System and method for accurately measuring length in compensation chain boxing process

A technology of precise measurement and compensation chain, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of no feedback alarm function, time-consuming and laborious rework adjustment, and decreased device accuracy, so as to achieve small space, eliminate torque tension, reduce effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

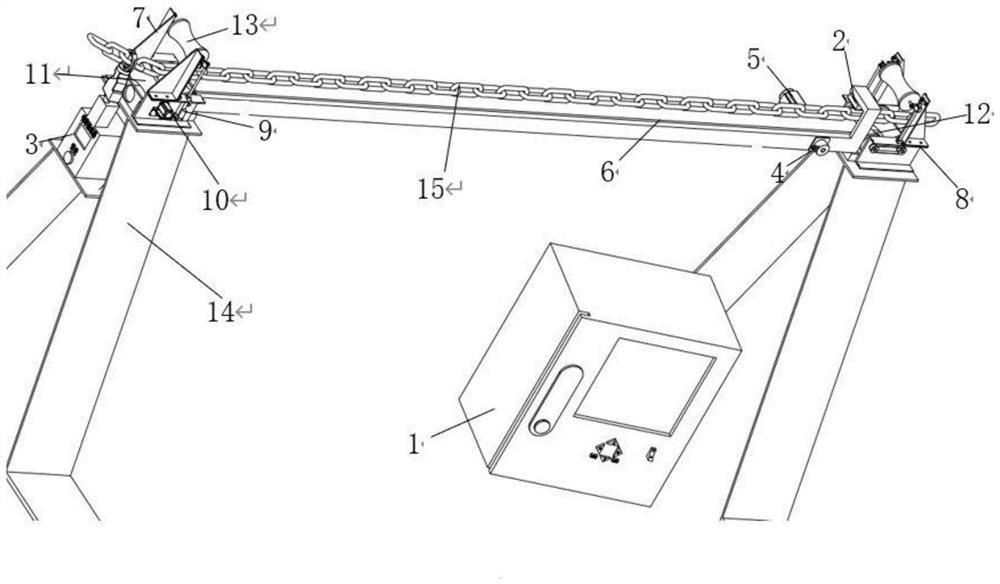

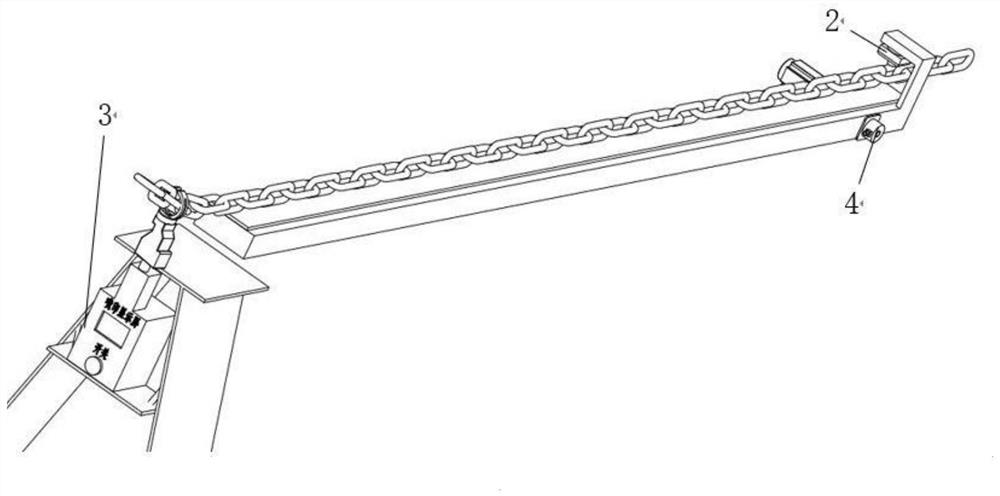

[0050] figure 1 It is a schematic diagram of the overall structure of an embodiment of the present invention. The device includes a main control device 1 and a length measuring device, a transmission device, a clamping device, and a compensation chain 15 arranged on a supporting platform 14 .

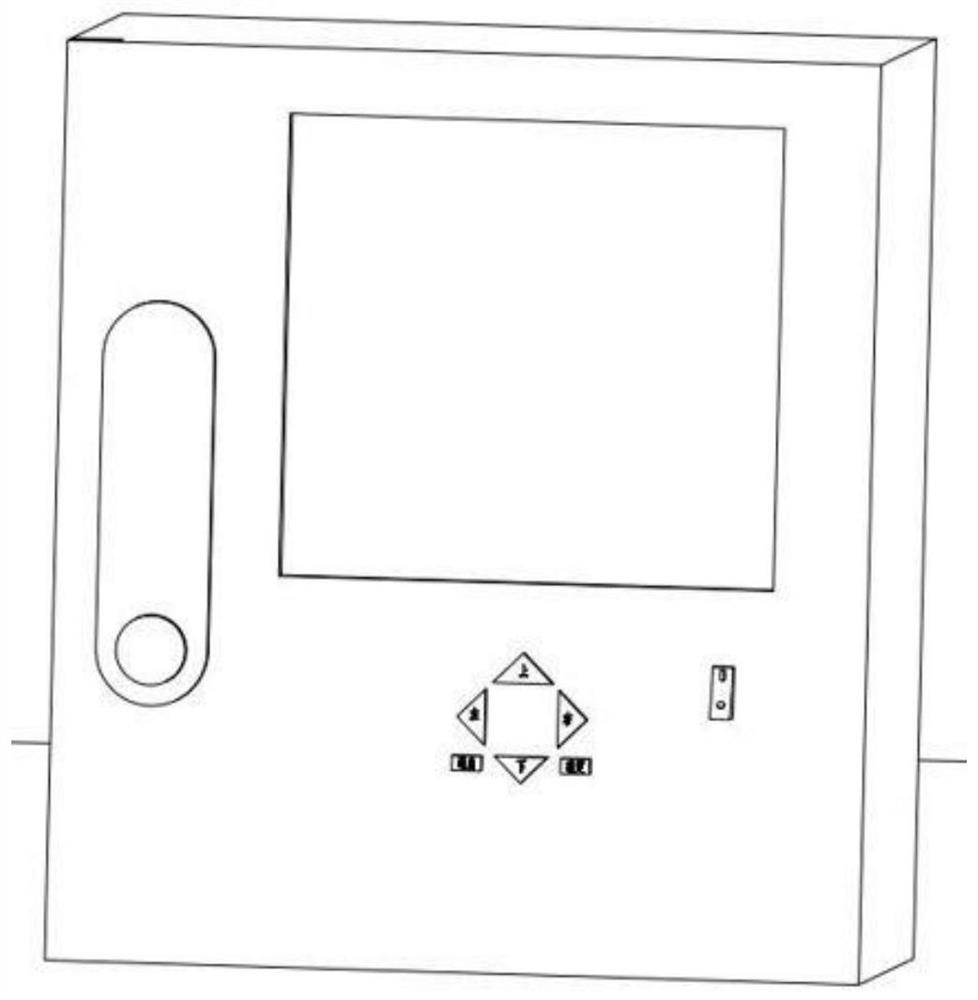

[0051] figure 2 It is a schematic diagram of the main control device of an embodiment of the present invention. Such as figure 2 The main control device 1 shown is placed near the chain outlet end under the right end of the support platform 14, and is used to electrically control the working and running of the length measuring device, the transmission device, the clamping device, and the compensation chain 15. It includes a switch, a touch screen and a number of common control buttons, through which the inkjet printer 3 and the hollow shaft encode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com