Welding paste printing quality prediction method and system based on IGA-DNN

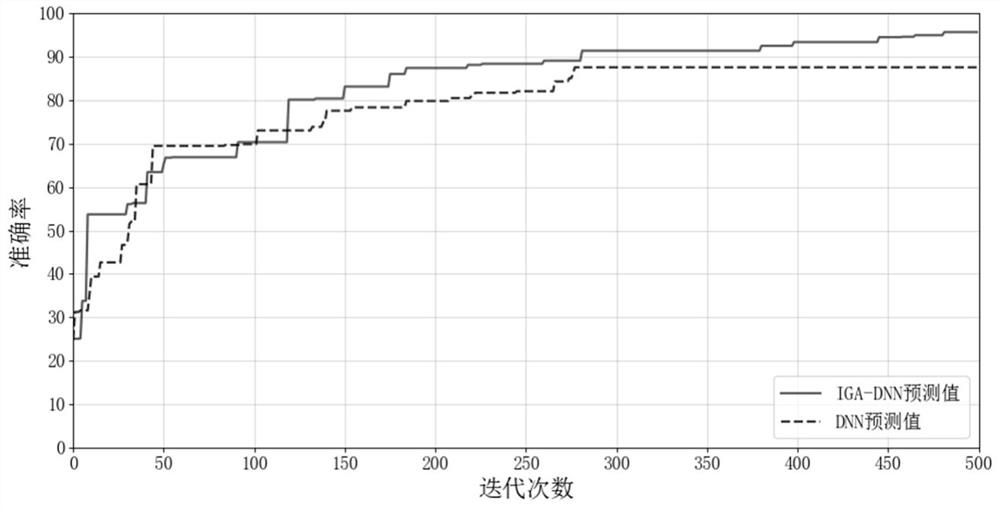

A technology for solder paste printing and quality prediction, applied in prediction, neural learning methods, biological neural network models, etc., can solve the problems of reduced prediction accuracy, slow convergence speed, and failure to meet the use requirements, so as to improve the accuracy of prediction , Improve the effect of convergence speed and precision, high precision and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The invention will be further described in detail below with reference to the accompanying drawings:

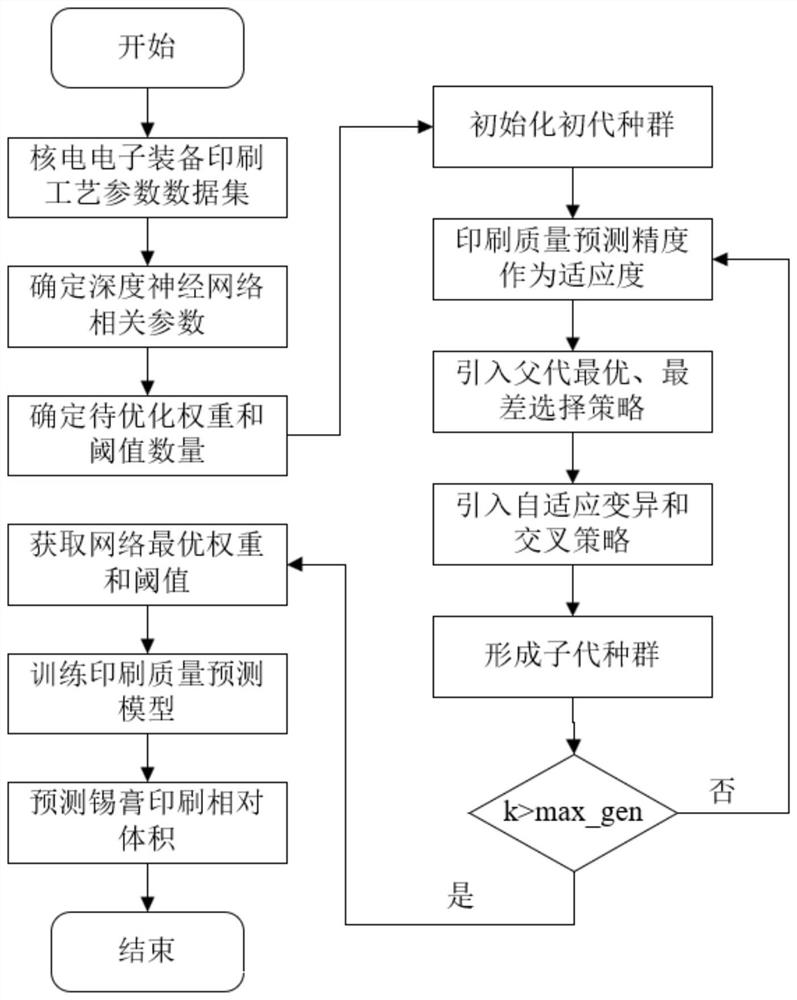

[0053] Such as figure 2 As shown, a prediction method of solder paste printed quality prediction based on a deep neural network (IgA-DNN) based on genetic algorithm, including the following steps:

[0054] S1, collecting the solder paste printing process parameters with the solder paste printed by the solder paste printing process parameters, and pretreats the collected raw data;

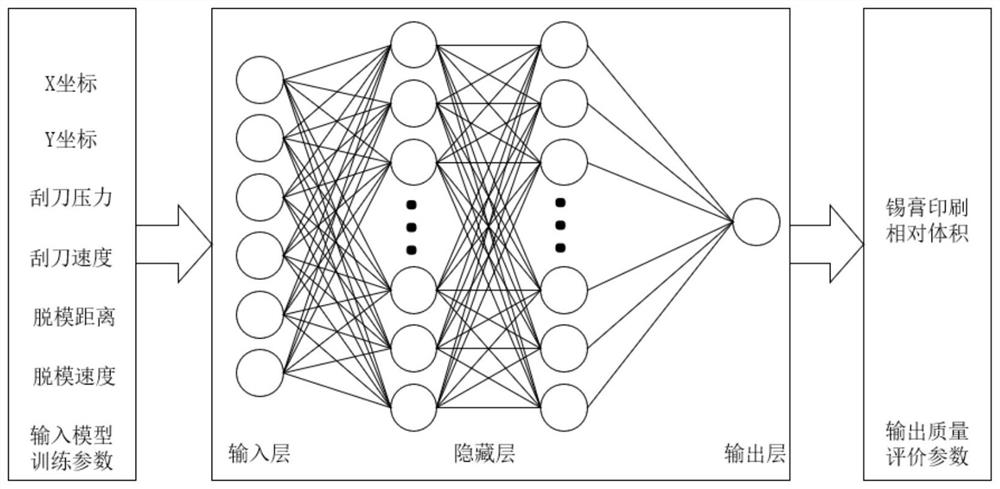

[0055] Specifically, according to the actual requirements of the solder paste print in surface mounting techniques to determine the process parameters optimized control, by analyzing the process parameters of the printed quality of the solder paste, the solder paste printing process parameters include X coordinate, Y coordinate, scraper pressure , Blade speed, demolding speed, and release distance, the above six solder paste printing process parameters are key factors affecting the quality of so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com