Phase-change film temperature control material

A technology of phase-change materials and thin films, which is applied in the fields of modification by liquid cooling, modification by conduction heat transfer, cooling/ventilation/heating modification, etc. It can solve the problems that the temperature rise of electronic components cannot be effectively alleviated, and achieve excellent heat dissipation. Effects of management ability, improvement of thermal conductivity, and improvement of latent heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

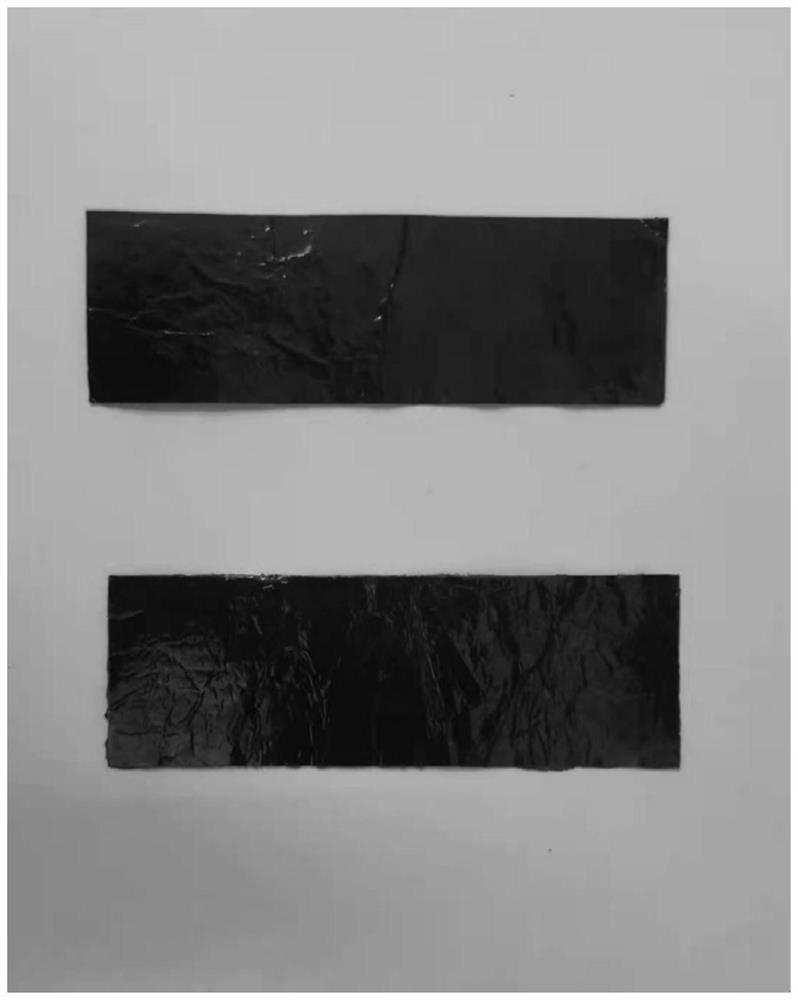

[0025] A phase-change film temperature control material has a three-layer structure, the middle layer is a phase-change microcapsule film, and the upper and lower layers are high thermal conductivity graphite films.

[0026] Preparation of phase change thin film temperature control material: use high thermal conductivity graphite film as substrate, put 0.544g n-tetradecane phase change microcapsule powder into a mold with an internal area of 40*100mm, and cover the top of the microcapsule with high thermal conductivity graphite film , pressurized by a tablet press, and the thickness is adjusted by rolling with a roller to make a phase change film temperature control material.

[0027] The phase change microcapsule film density of the obtained phase change film temperature control material is 0.744g / cm 3 , the thickness is 0.175mm.

Embodiment 2

[0029] A phase-change film temperature control material has a three-layer structure, the middle layer is a phase-change microcapsule film, and the upper and lower layers are high thermal conductivity graphite films.

[0030] Preparation of phase change thin film temperature control material: with high thermal conductivity graphite film as the substrate, put 0.552g of n-eicosane phase change microcapsule powder into a mold with an internal area of 40*100mm, and cover the upper part of the microcapsule with high thermal conductivity graphite film. It is pressed by a tablet press, and then rolled by a roller to adjust the thickness to make a phase change material film. The density of the obtained phase change microcapsule film is 0.732g / cm 3 , the thickness is 0.172mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap