Aquatic product screening equipment

A technology for screening equipment and aquatic products, which is applied to sieves, grilles, and the separation of solids from solids by air flow. Improve screening efficiency and screening effect, improve screening efficiency, and improve the effect of sorting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

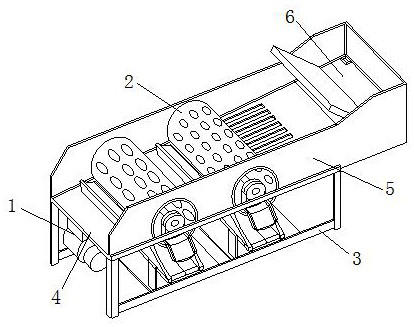

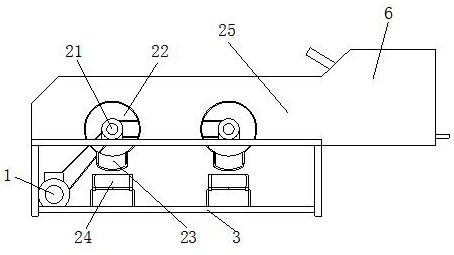

[0023] as attached figure 1 to attach Figure 4 Shown:

[0024] The present invention is an aquatic product screening equipment, its structure includes a motor 1, a screening machine main body 2, a chassis 3, a discharge port 4, an outer baffle 5, and a cleaning device 6, and the motor 1 is located on the left side of the screening machine main body 2 Bottom, the motor 1 is installed on the left rear surface of the bottom side of the chassis 3, the screening machine main body 2 is installed on the top of the chassis 3, the left side of the top of the screening machine main body 2 is provided with a discharge port 4, the screening The front and rear sides of the machine main body 2 are provided with outer baffles 5, and the upper part of the right side of the screening machine main body 2 is provided with a cleaning device 6, and the front, rear and right sides of the cleaning device 6 are provided with outer baffles 5. 2 includes a rotating shaft 21, a screening drum 22, a m...

Embodiment 2

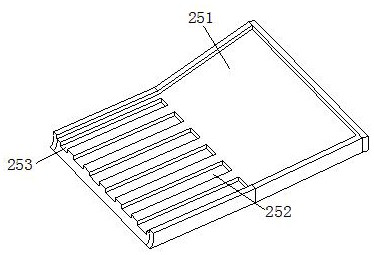

[0030] as attached Figure 5 to attach Figure 8 Shown:

[0031] Wherein, the screening drum 22 includes a drum wall 221, a screening opening 222, a protection device 223, and a screening plate 224. The screening drum 22 is provided with a screening opening 222 outside, and the screening plate 224 is installed in the left middle part of the screening drum 22. The middle part of the right side of the screening drum 22 is equipped with a sorting opening 253, and the protection device 223 is installed on the upper surface of the middle part of the screening plate 224. The screening drum 22 is made of aluminum, which has good corrosion resistance and rust resistance. Long service life, the surface of the right part of the screening drum 22 is provided with eight screening openings 222 horizontally, and eight screening openings 222 are arranged around the longitudinal direction, and the openings are relatively small, which are respectively installed corresponding to the eight sort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com