Livestock and poultry feed additive capable of replacing grease and preparation method of livestock and poultry feed additive

A livestock and poultry feed and additive technology, applied in the molding or processing of animal feed, feed, animal feed, etc., can solve problems such as high triglyceride and cholesterol, unfavorable long-term storage of feed, and reduce feed intake of livestock and poultry, etc., to achieve Improve satiety, be beneficial to human health, and improve the effect of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

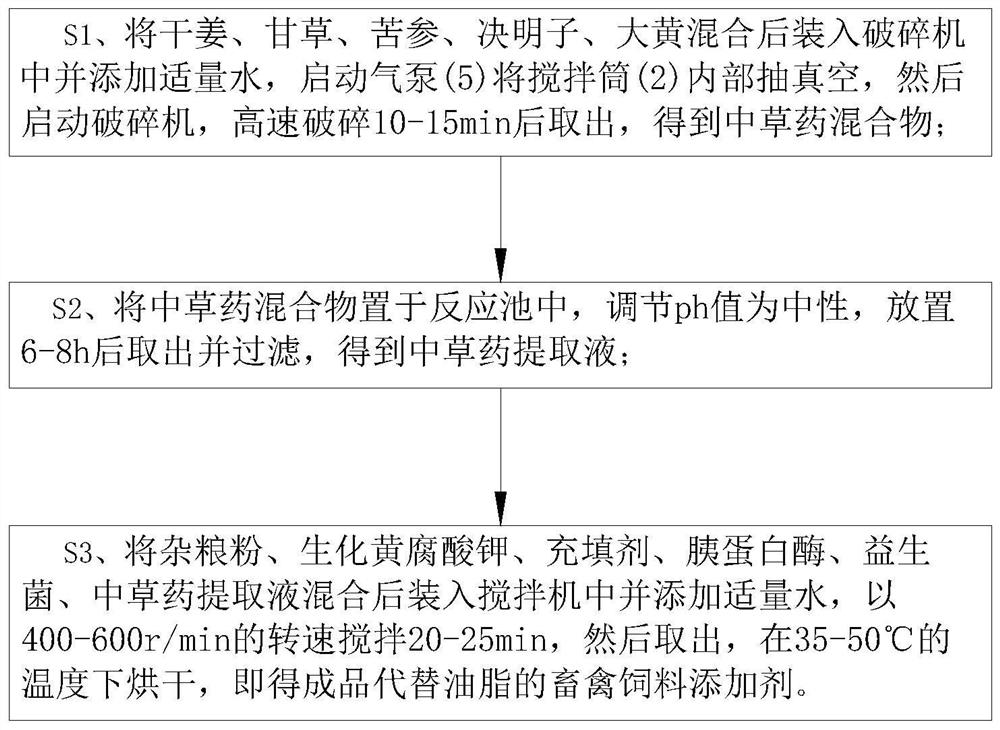

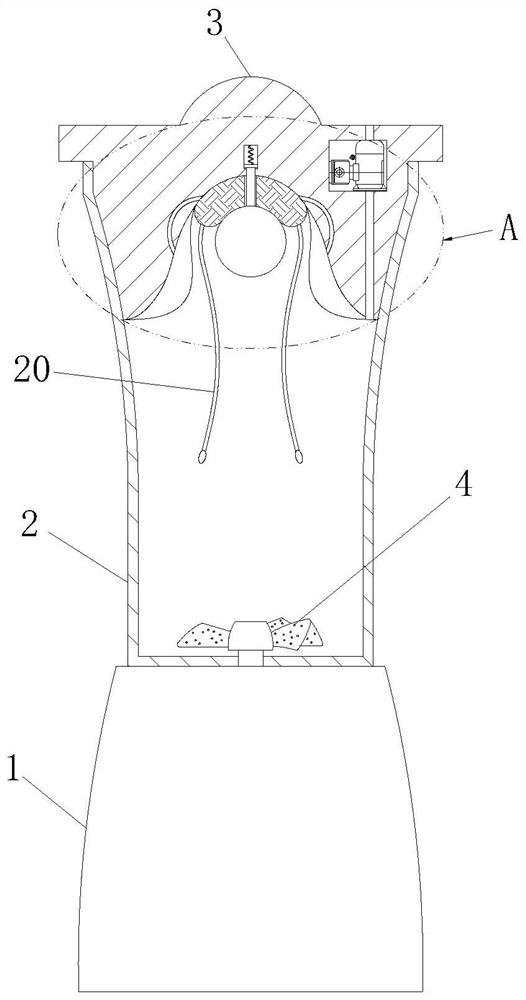

Method used

Image

Examples

Embodiment 1

[0043] A feed additive for livestock and poultry instead of fat, which is composed of the following raw materials in parts by weight: 60 parts of miscellaneous grain powder, 5-10 parts of biochemical potassium fulvic acid, 3-6 parts of filler, 8-12 parts of trypsin, probiotic 3-5 parts of bacteria, 6-8 parts of Chinese herbal medicine; wherein, the miscellaneous grain powder is composed of the following raw materials in parts by weight: 25-28 parts of corn flour, 25-28 parts of pumpkin powder, and 10-14 parts of green tea powder.

[0044] Each raw material is produced into a feed additive for livestock and poultry instead of oil according to the preparation method, and after being combined with the feed, the livestock and poultry are continuously fed for one month, and the body fat percentage of the livestock and poultry is inspected.

Embodiment 2

[0046] A feed additive for livestock and poultry instead of fat, which is composed of the following raw materials in parts by weight: 65 parts of miscellaneous grain powder, 5-10 parts of biochemical potassium fulvic acid, 3-6 parts of filler, 8-12 parts of trypsin, probiotic 3-5 parts of bacteria, 6-8 parts of Chinese herbal medicine; wherein, the miscellaneous grain powder is composed of the following raw materials in parts by weight: 25-28 parts of corn flour, 25-28 parts of pumpkin powder, and 10-14 parts of green tea powder.

[0047] Each raw material is produced into a feed additive for livestock and poultry instead of oil according to the preparation method, and after being combined with the feed, the livestock and poultry are continuously fed for one month, and the body fat percentage of the livestock and poultry is inspected.

Embodiment 3

[0049] A feed additive for livestock and poultry instead of fat, the additive is composed of the following raw materials in parts by weight: 70 parts of miscellaneous grain powder, 5-10 parts of biochemical potassium fulvic acid, 3-6 parts of filler, 8-12 parts of trypsin, probiotic 3-5 parts of bacteria, 6-8 parts of Chinese herbal medicine; wherein, the miscellaneous grain powder is composed of the following raw materials in parts by weight: 25-28 parts of corn flour, 25-28 parts of pumpkin powder, and 10-14 parts of green tea powder.

[0050] Each raw material is produced into a feed additive for livestock and poultry instead of oil according to the preparation method, and after being combined with the feed, the livestock and poultry are continuously fed for one month, and the body fat percentage of the livestock and poultry is inspected.

[0051] The body fat percentages of the obtained livestock and poultry are shown in Table 1.

[0052] body fat percentage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com