High-temperature gas reverse double-rotation efficient mixer matched with acetylene furnace

A gas mixing and acetylene furnace technology, applied in chemical instruments and methods, detailed information of chemical/physical/physical-chemical reactors, chemical/physical/physical-chemical processes, etc., and can solve the problem that the specific structure and realization method of the mixer are not disclosed And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

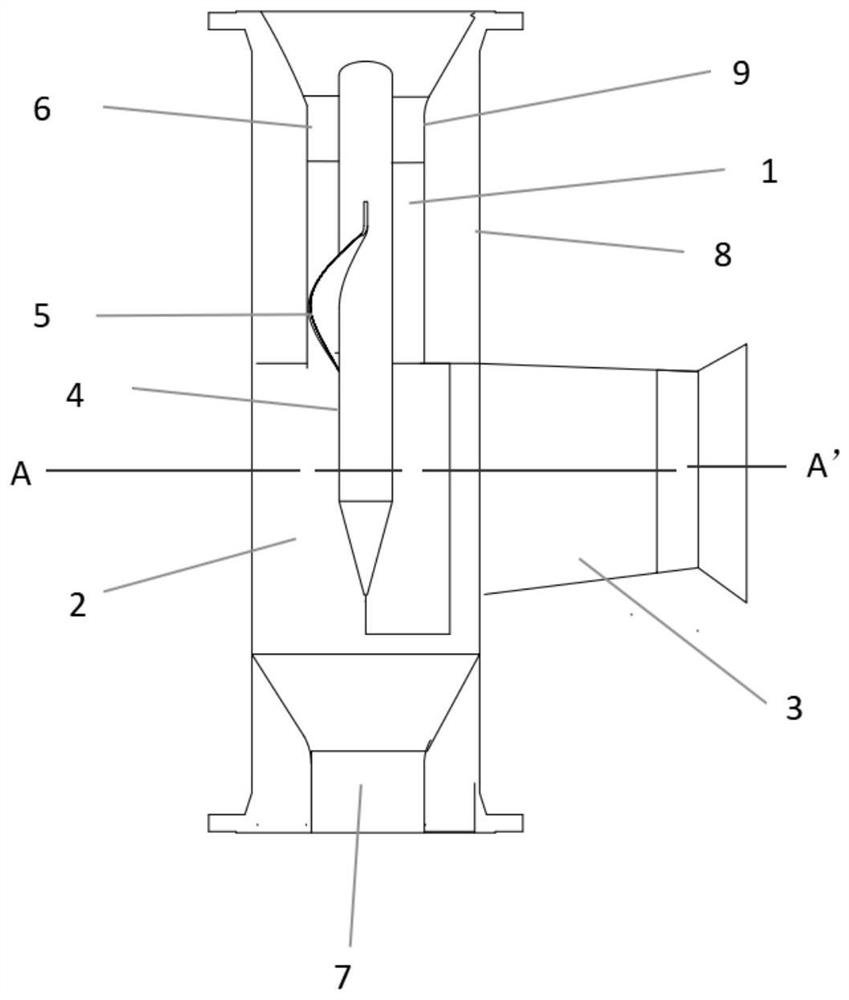

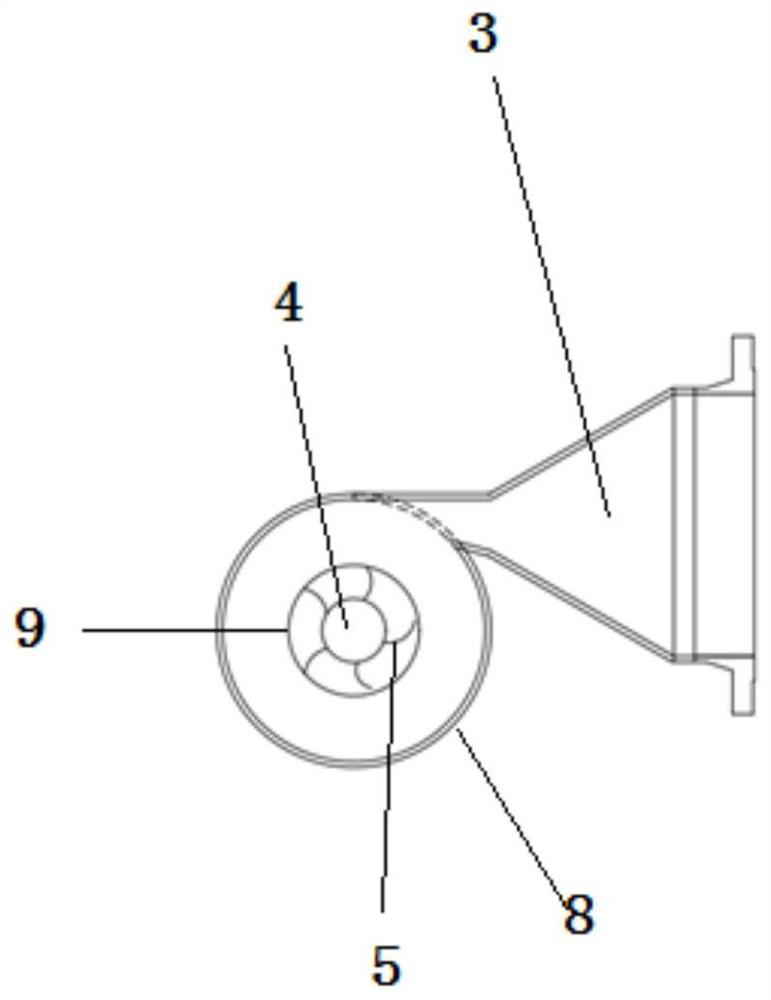

[0040] A gas reverse double-rotation mixer matched with the acetylene furnace, its structure is as follows figure 1 As shown, it includes a first air inlet 1, a gas mixing area 2 and a second air inlet 3; the first air inlet 1 is a port of a shell 8 with a cylindrical structure, and the lower part of the first air inlet 1 The area inside the housing 8 is the gas mixing zone 2, and the first air inlet 1 is used to send the first gas into the gas mixing zone 2; the second air inlet 3 communicates with the housing 8 at the position of the gas mixing zone 2, and uses Then send the second gas into the gas mixing zone 2.

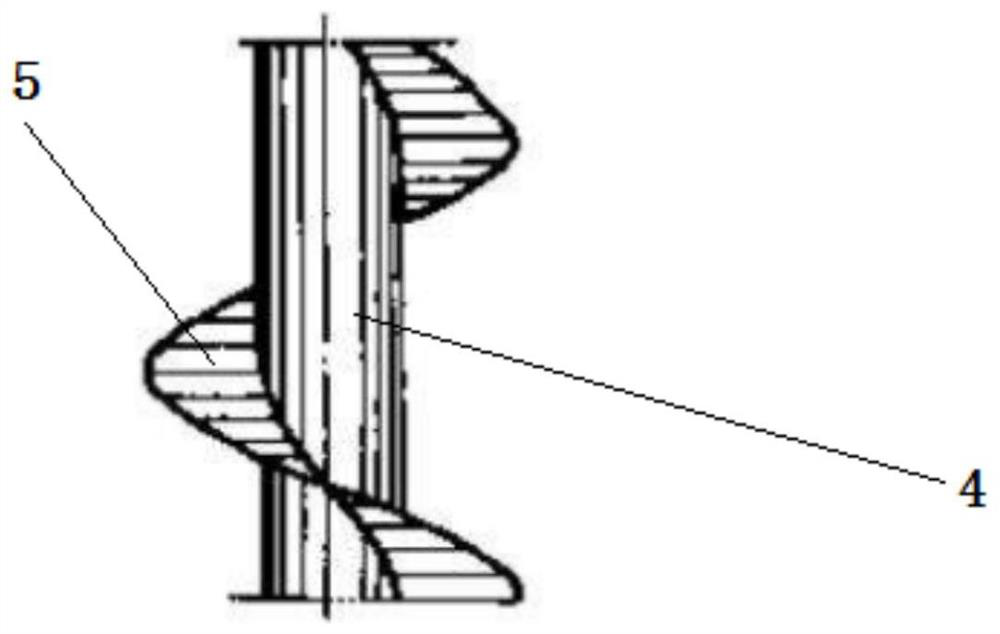

[0041] The specific and preferred structure of the first air inlet 1 is as follows: the center of the first air inlet 1 is provided with an inner sleeve 9, positioning fins 6 and cone columns 4; the inner sleeve 9 has the same outer diameter as the inner diameter of the housing 8 1. The inner diameter is a funnel-shaped closed structure, which is arranged in the ...

Embodiment 2

[0046] A raw material gas mixing process in the process of producing acetylene from natural gas, it uses the gas inverse double-rotation mixer matched with the acetylene furnace in embodiment 1, comprising the following steps:

[0047] Send one of oxygen or hydrocarbon gas into the inner sleeve 9 from the mouth of the first air inlet 1;

[0048] The other one of oxygen or hydrocarbon gas is sent into the shell from the mouth of the second air inlet 3;

[0049] The two gases are mixed in the gas mixing zone 2 .

[0050] Preferably, the gas velocity entering the gas mixing zone 2 from the first air inlet 1 is 120~320m / s; the gas velocity entering the gas mixing zone 2 from the first air inlet 1 is 120~280m / s; The mixing time in the mixing zone is 0.001~0.01S, and then enters the acetylene reaction furnace from the exhaust part 7; the gas entering the gas mixing zone in the shell 8 from the mouth of the second air inlet 3 is natural gas raw material gas; the gas mixing The temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com