Mullite ceramic with high strength and low shrinkage performance, and preparation method thereof

A low-shrinkage, high-strength technology, applied in the field of mullite ceramics and its preparation, to achieve the effects of inhibiting a large amount of generation, inhibiting ceramic shrinkage, and improving ceramic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

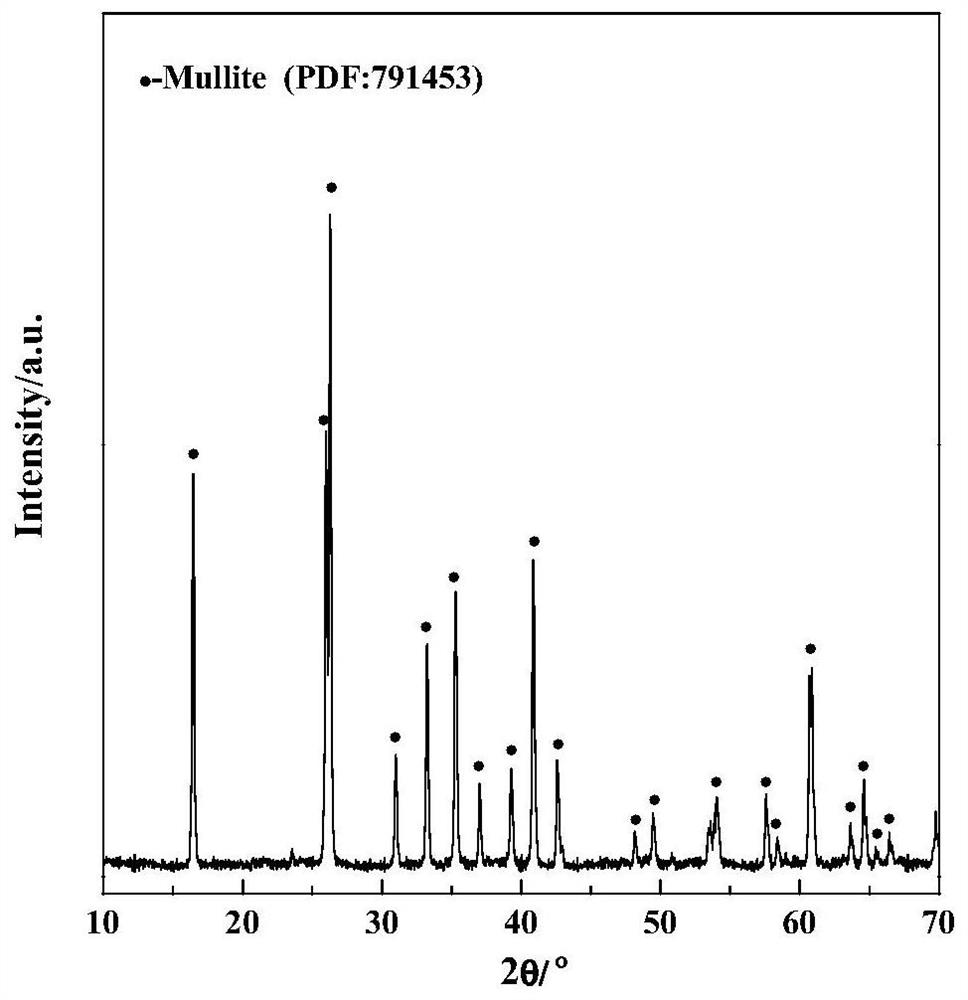

[0022] For the second solution in the present invention, a method for preparing mullite ceramics with high strength and low shrinkage properties is provided, which is used to prepare mullite ceramics with high strength and low shrinkage properties in the aforementioned first solution. Laishi ceramics, the steps include: mixing the silicon source and the aluminum source according to the mass ratio (40-50): (50-60) and ball milling, and then sieving, preferably 250-500 mesh sieve, to obtain the mixture; and then The mixture is pressed into a green body and fired at high temperature to obtain mullite ceramics with high strength and low shrinkage. Among them, the specific process conditions of high-temperature firing are preferably: the firing temperature is 1550-1650° C., the heating rate is 10-20° C. / min, and the holding time is 10-30 minutes.

[0023]Among them, the silicon source is coal series kaolin, and the preferred particle size of the silicon source is 20-50 μm; in terms...

Embodiment 1

[0029] In this embodiment, the steps for preparing mullite ceramics with high strength and low shrinkage properties are as follows:

[0030] (1) Coal series kaolin is selected as the silicon source, in terms of mass percentage, the chemical composition of the silicon source is specifically: SiO 2 45%, Al 2 o 3 36%, Fe 2 o 3 0.011%, CaO 0.035%, K 2 O-Na 2 O 0.015%, carbonaceous 15%; the particle size of the silicon source is 20-50 μm.

[0031] (2) Select α-Al 2 o 3 and Al(OH) 3 The mixture of the aluminum source is used as the aluminum source, and the chemical composition of the aluminum source is specifically: α-Al 2 o 3 65%, Al(OH) 3 35%; the particle size of the aluminum source is 10-20 μm.

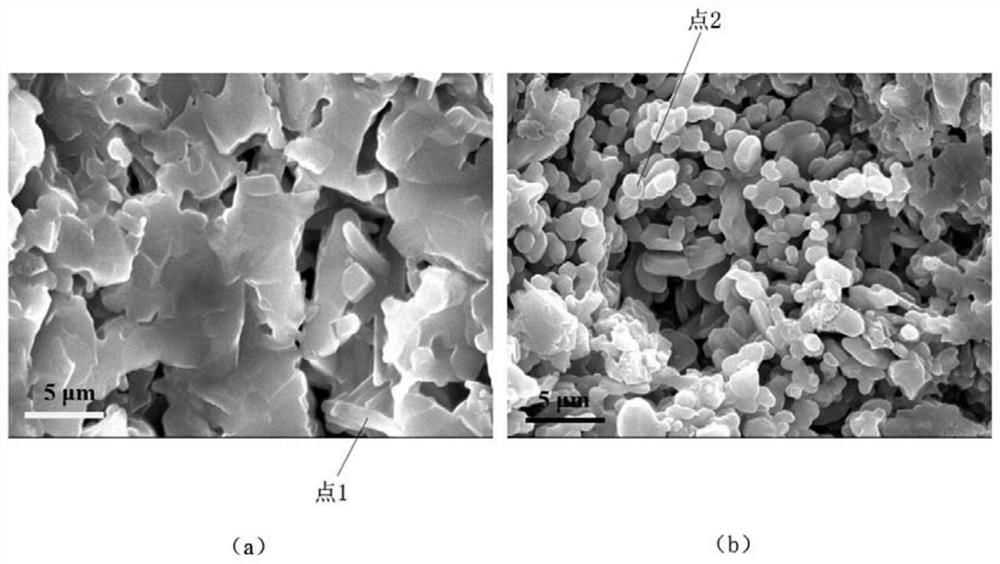

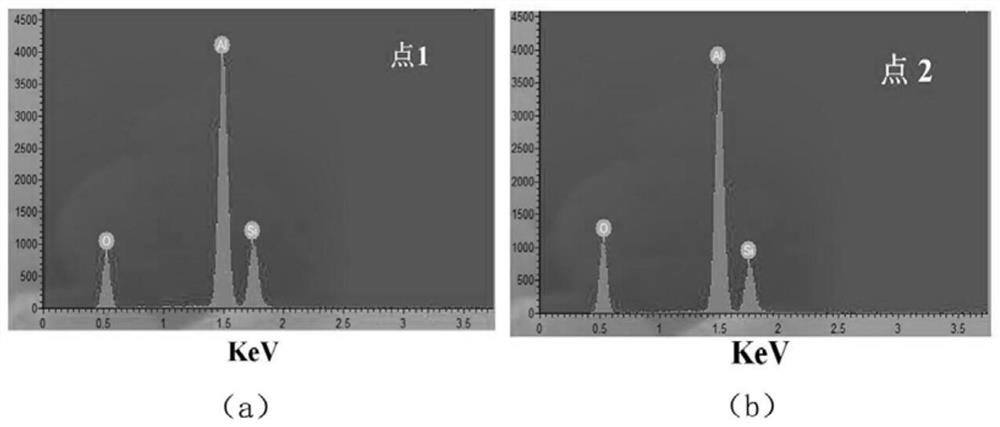

[0032] (3) After the silicon source and the aluminum source are mixed and ball milled according to the mass ratio of 50:50, the mixture is sieved with a 300-mesh sieve to obtain the mixture; Under the conditions of 15°C / min and holding time of 20min, the green body is f...

Embodiment 2

[0035] In this embodiment, the steps for preparing mullite ceramics with high strength and low shrinkage properties are as follows:

[0036] (1) Coal series kaolin is selected as the silicon source, in terms of mass percentage, the chemical composition of the silicon source is specifically: SiO 2 40%, Al 2 o 3 38%, Fe 2 o 3 0.01%, CaO 0.03%, K 2 O-Na 2 O 0.01%, carbonaceous 18%; the particle size of the silicon source is 20-50 μm.

[0037] (2) Select α-Al 2 o 3 and Al(OH) 3 The mixture of the aluminum source is used as the aluminum source, and the chemical composition of the aluminum source is specifically: α-Al 2 o 3 60%, Al(OH) 3 40%; the particle size of the aluminum source is 10-20 μm.

[0038] (3) After the silicon source and the aluminum source are mixed and ball milled in a mass ratio of 45:55, the mixture is sieved with a 250-mesh sieve to obtain the mixture; Under the conditions of 10°C / min and holding time of 10min, the green body is fired to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com