Preparation process of a cool-feeling three-dimensional spacer knitted fabric and its knitted fabric

A knitted fabric and preparation process technology, applied in knitting, warp knitting, rayon manufacturing and other directions, can solve the problems of accelerated sweat dissipation, poor thermal conductivity, poor dyeing, etc., and achieve a high degree of environmental protection and good bactericidal effect. , to avoid the effect of sensitive skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

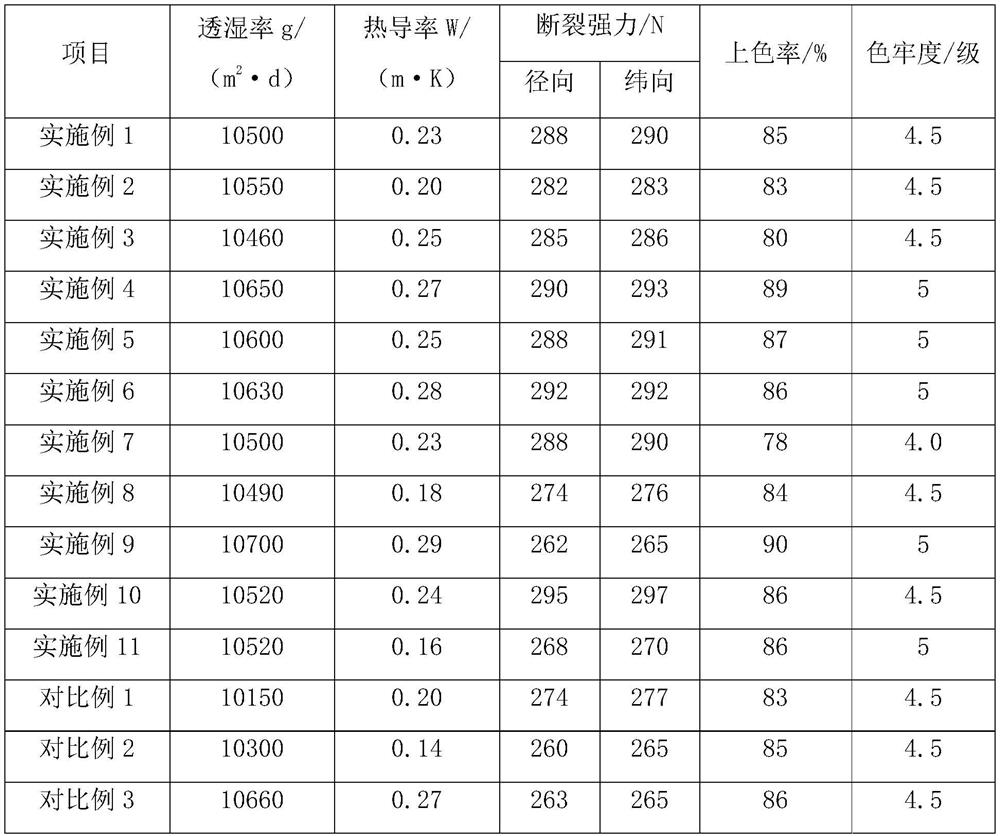

Examples

preparation example Construction

[0044] Preparation example of ultra-high molecular weight polyethylene fiber yarn

[0045] The ultra-high molecular weight polyethylene in the following raw materials was purchased from Shenzhen Tellus New Material Technology Co., Ltd.; the white oil was purchased from Wuhan Xindongyi Chemical Co., Ltd.; the colorant was purchased from Shandong Yunze Biotechnology Co., Ltd., model SS-01; Etherimide was purchased from Suzhou Mutual Innovative Materials Co., Ltd.; other raw materials and equipment were commercially available.

preparation example 1

[0046] Preparation Example 1: UHMWPE fiber yarn was prepared by the following method:

[0047] S11. After weighing and mixing 8kg of ultra-high molecular weight polyethylene, 48kg of white oil and 2kg of colorant, stir for 30min under the conditions of 150°C and 700r / min, then add 2kg of nano-mica powder and 1kg of nano-silver powder and continue to stir for 5min to obtain Spinning solution; ultra-high molecular weight polyethylene molecular weight 5 million;

[0048] S12, placing the spinning solution obtained in S11 in a twin-screw extruder, and under the conditions of 180 ° C and an extrusion speed of 150 r / min, through extrusion and spinning to obtain a semi-finished product;

[0049] S13. The semi-finished product prepared in S12 is stretched in three passes. The first stretch is 12 times, the hot air temperature is 120°C, the second stretch is 1.8 times, the hot air temperature is 130°C, and the third stretch is 130°C. The elongation ratio is 1.1 times, the hot air temp...

preparation example 2

[0050] Preparation Example 2: UHMWPE fiber yarn was prepared by the following method:

[0051] S11. After weighing and mixing 5kg of ultra-high molecular weight polyethylene, 40kg of white oil and 1kg of colorant, stir for 25min at 130°C and 550r / min, then add 1kg of nano-mica powder and 0.5kg of nano-silver powder and continue to stir for 3min. The spinning solution is obtained; the molecular weight of ultra-high molecular weight polyethylene is 8 million;

[0052] S12, placing the spinning solution obtained in S11 in a twin-screw extruder, and under the conditions of 180 ° C and an extrusion speed of 150 r / min, through extrusion and spinning to obtain a semi-finished product;

[0053] S13. The semi-finished product prepared in S12 is stretched in three passes. The first stretch is 12 times, the hot air temperature is 120°C, the second stretch is 1.8 times, the hot air temperature is 130°C, and the third stretch is 130°C. The elongation ratio is 1.1 times, the hot air temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com