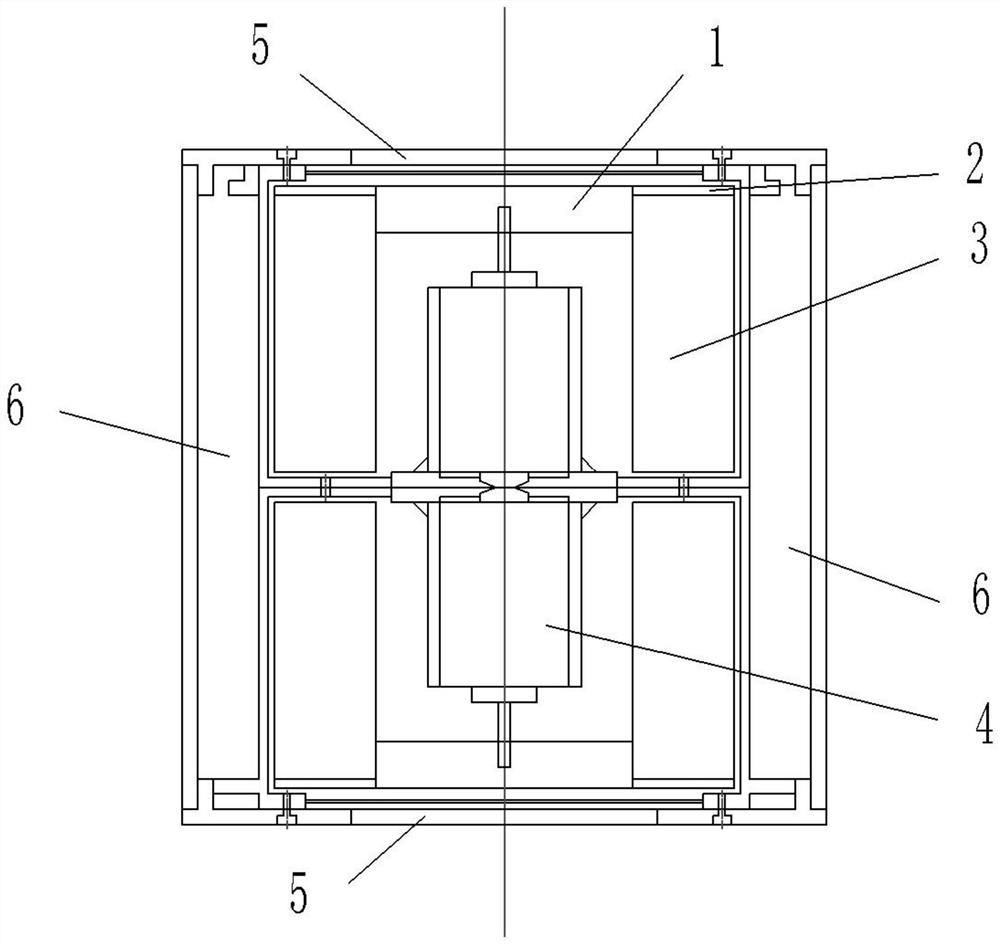

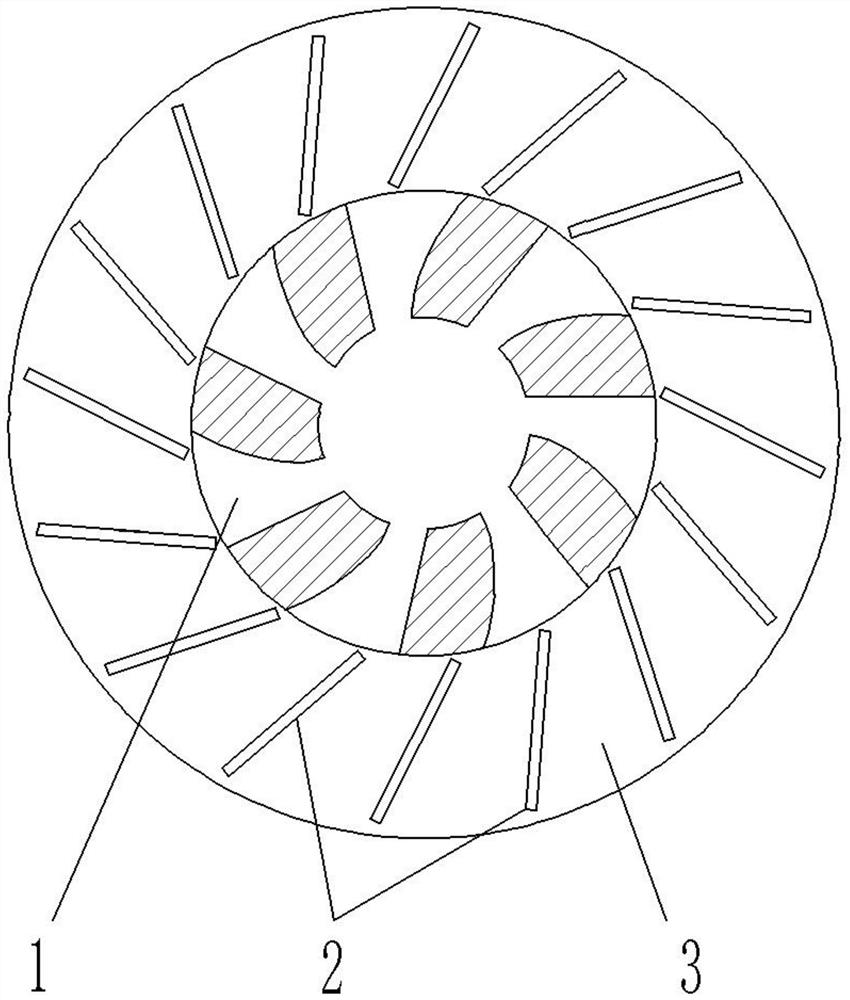

Centrifugal contra-rotating air pump with two ends axially feeding air

A technology of axial air intake and air transfer, applied in radial flow pumps, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of low suction capacity, poor practicability, and high energy consumption of air pumps. To achieve the effect of compact structure, long service life and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] A double impeller counter-rotating wind wheel structure suitable for small wind power generators of the present invention is used to conduct wind tunnel blowing research, and the incoming wind speeds are respectively 7m / s, 8m / s, 9m / s and 10m / s. The output power of the single-wheel wind rotor structure and the counter-rotating wind rotor structure of the same design size (same airfoil and the same maximum rotation radius) were measured respectively, and the experimental results are as follows:

[0034] Table 1 Experimental structure

[0035]

[0036] It can be seen from Table 1 that the dual-blade counter-rotating wind rotor structure of the present invention has at least 41% improvement in wind energy utilization rate compared with the conventional single-blade wind rotor structure under moderate wind conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com