Coating method and device for heating non-combustion reconstituted tobacco

A heat-not-burn and reconstituted tobacco leaf technology, which is applied in transportation and packaging, tobacco, and tobacco preparation, can solve the problems of difficult penetration of coating liquid, affecting the processing process, and substandard coating rate, so as to improve thickness and enhance penetration The effect of good performance and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

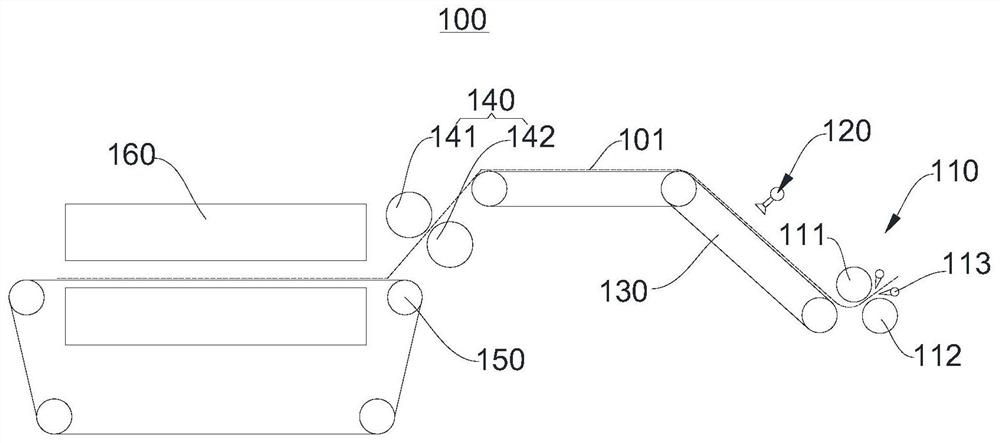

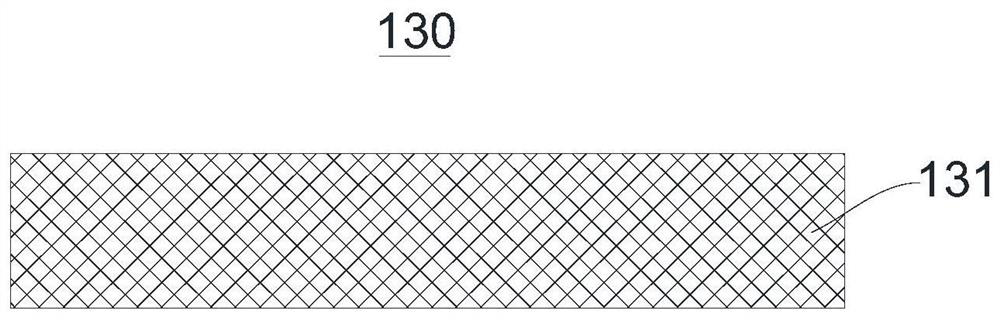

[0087] The application provides a coating method for heat-not-burn reconstituted tobacco, comprising:

[0088] S1, coating step.

[0089] During the coating process, the temperature of the coating solution was controlled to be 60°C, and the base sheet 101 was quantitatively 55g / m2. 2 , the hardness of the first coating roll 111 is 30P&J; the hardness of the second coating roll 112 is 130P&J. The line pressure of the coating roll is 10kN / m, the feeding amount of the coating liquid is 6.5 tons / hour, and the return flow rate of the coating liquid is 3.5 tons / hour. The width of the paper machine is 3m, the speed of the paper machine is 170m / min, and the concentration of the coating liquid is 55%±2%.

[0090] S2, strengthen the penetration step.

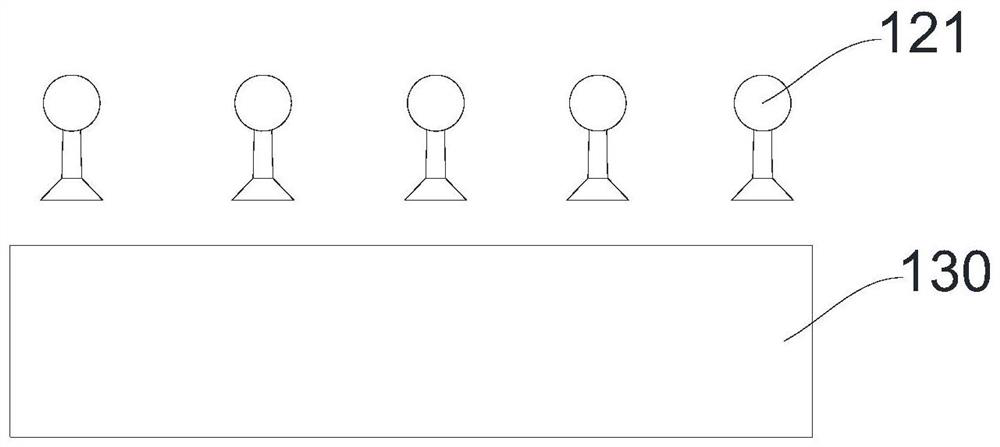

[0091] In this application, a plurality of steam nozzles 121 are used to wet-heat the semi-finished tobacco leaves; the plurality of steam nozzles 121 are evenly distributed in the direction perpendicular to the moving direction of the...

Embodiment 2

[0097] The application provides a coating method for heat-not-burn reconstituted tobacco, comprising:

[0098] S1, coating step.

[0099] During the coating process, the temperature of the coating solution is controlled to be 55°C, and the base sheet 101 is quantitatively 55g / m2. 2 , the hardness of the first coating roll 111 is 20P&J; the hardness of the second coating roll 112 is 120P&J. The line pressure of the coating roll is 10kN / m, the feeding amount of the coating liquid is 6.5 tons / hour, and the return flow rate of the coating liquid is 3.5 tons / hour. The width of the paper machine is 3m, the speed of the paper machine is 170m / min, and the concentration of the coating liquid is 55%±2%.

[0100] S2, strengthen the penetration step.

[0101] In this application, a plurality of steam nozzles 121 are used to wet-heat the semi-finished tobacco leaves; the plurality of steam nozzles 121 are evenly distributed in the direction perpendicular to the moving direction of the s...

Embodiment 3

[0107] The application provides a coating method for heat-not-burn reconstituted tobacco, comprising:

[0108] S1, coating step.

[0109] During the coating process, the temperature of the coating liquid was controlled to be 75°C, and the base sheet 101 was quantitatively 55g / m2. 2 , the hardness of the first coating roll 111 is 40P&J; the hardness of the second coating roll 112 is 140P&J. The line pressure of the coating roll is 10kN / m, the feeding amount of the coating liquid is 6.5 tons / hour, and the return flow rate of the coating liquid is 3.5 tons / hour. The width of the paper machine is 3m, the speed of the paper machine is 170m / min, and the concentration of the coating liquid is 55%±2%.

[0110] S2, strengthen the penetration step.

[0111] In this application, a plurality of steam nozzles 121 are used to wet-heat the semi-finished tobacco leaves; the plurality of steam nozzles 121 are evenly distributed in the direction perpendicular to the moving direction of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com