Preparation method of cobaltosic oxide particles and calcining equipment

A technology of cobalt tetroxide particles and cobalt tetroxide, applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of cobalt carbonate sticking, affecting the fluidity of materials, large agglomerates, etc., to avoid sticking and agglomeration, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

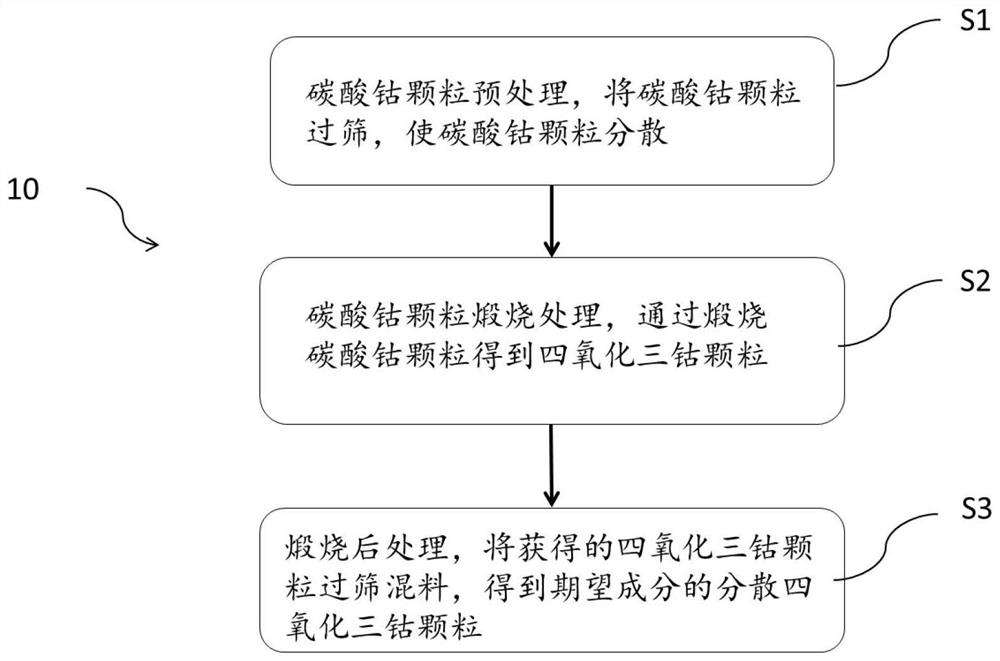

[0039] The preparation method of the tricobalt tetroxide particles is not limited to steps S1 to S3 shown in the figure, and can be appropriately changed. For example, before step S1, if the cobalt carbonate particles are prepared by a wet method, the dehydration process or moisture control process of the cobalt carbonate particles may be required, and the sieving treatment in steps S1 and S3 can be performed multiple times. The dehydration process or moisture control process before step S1 and the sieving before calcination of step S1 can effectively separate the cohesive and agglomerated cobalt carbonate, and avoid the problem of uneven heating of the inner and outer particles of the cobalt carbonate massive agglomerate. The dehydration process or moisture control process before step S1 preferably controls the moisture content of cobalt carbonate to ≤4%. The sieved cobalt carbonate particles are more likely to roll with the calcination equipment in the calcination equipment,...

Embodiment 1

[0066] The particle size D50 of the cobalt carbonate particles used is 4.2 μm, the aluminum doping amount is 0.38%, the water content is 2%, the mesh size is 325, the rotary kiln speed is 1.0r / min, and the cobalt carbonate particle feed rate is 250kg / h.

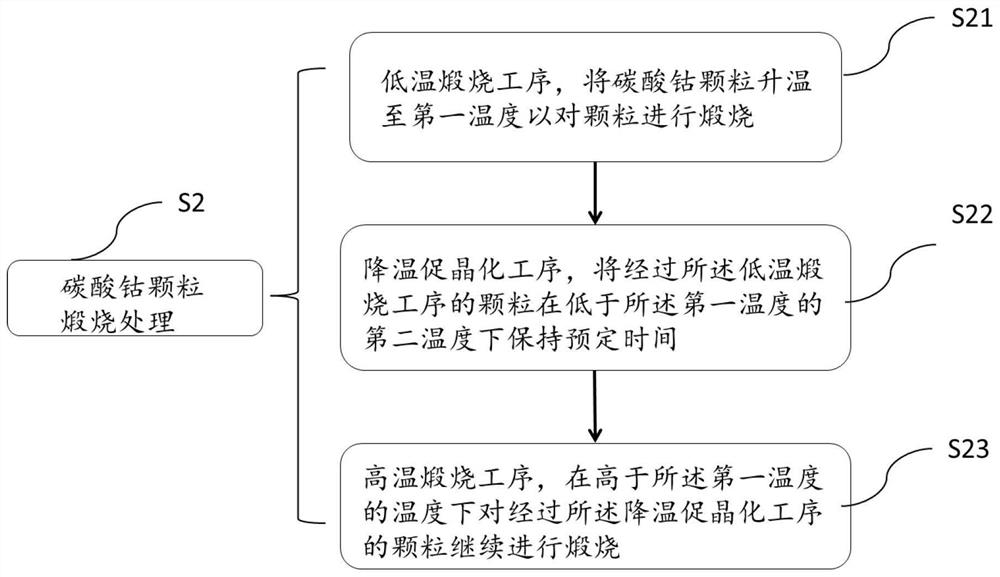

[0067] In step S2, in the low-temperature calcination process S21, the temperature is 200°C, and the residence time is 30min. At the end of the low-temperature calcination process S21, the conversion rate of cobalt carbonate is 19%, and the cobalt content is 50%; The residence time is 30min.

[0068] The particle size D50 of the cobalt tetroxide product obtained after sieving and mixing is 3.8 μm, the peak width of the particle size distribution is 0.66, and the specific surface area is 3.2m 2 / g.

[0069] Figure 4 Be according to the scanning electron micrograph (3000 times) of the product obtained in specific example 1 of the present invention. Figure 4 It can be seen in the figure that the obtained cobalt tetraoxide p...

Embodiment 2

[0071] The particle size D50 of the cobalt carbonate particles used is 4.7 μm, the aluminum doping amount is 0.65%, the moisture content is 4%, the mesh number of the cobalt carbonate particles is 200, the mesh number of the tricobalt tetroxide particles is 325, the rotary kiln speed is 1.5r / min, and the cobalt carbonate particles enter Material speed 300kg / h.

[0072] In step S2, in the low-temperature calcination process S21, the temperature is 350°C, and the residence time is 20min. At the end of the low-temperature calcination process S21, the conversion rate of cobalt carbonate is 26%, and the cobalt content is 52%; The residence time is 20min.

[0073] The particle size D50 of the cobalt tetroxide product obtained after mixing is 4.0 μm, the peak width of the particle size distribution is 0.68, and the specific surface area is 3.5m 2 / g.

[0074] Figure 5 It is a scanning electron micrograph (3000 times) of the product obtained in specific example 2 according to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com