Anti-fouling device for optical fiber sensor

An optical fiber sensor and anti-fouling technology, which is applied in the direction of grinding/polishing safety devices, grinding/polishing equipment, grinding machine parts, etc., can solve the problems of limited detection function, interference signal detection, dust generation, etc., to prevent Pollution, compact layout, and stable rust-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

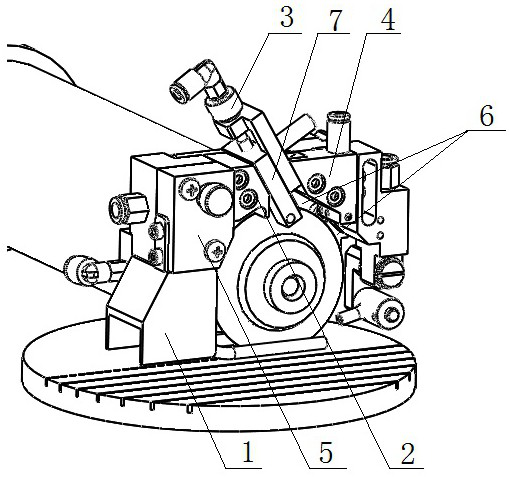

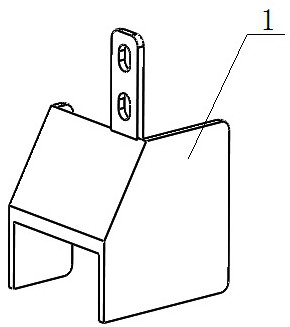

[0028] The invention provides an antifouling device for optical fiber sensors, which is in a semi-enclosed structure, see Figure 1-7 , including: fog collecting deflector 1, sewage intercepting plate 2, longitudinal air blowing assembly 3, horizontal air blowing assembly 4, front water spraying plate 5 and rear bottom plate 6;

[0029] The mist-collecting deflector 1 is arranged on the front water spray plate 5, and is located below the front water spray plate 5; On the rear bottom plate 6, and the front water spray plate 5, the sewage interceptor plate 2, the longitudinal air blowing assembly 3 and the horizontal air blowing assembly 4 are arranged in sequence from left to right;

[0030] Wherein, the optical fiber sensor 7 is arranged on the longitudinal air blowing assembly 3 .

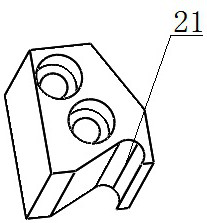

[0031] Further, see Figure 4 , 5 , the longitudinal blowing assembly 3 includes: a longitudinal blowing main body 31 and a longitudinal blowing joint 32 arranged on the longitudinal blowing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com