Ethylene-vinyl alcohol copolymer (EVOH) containing resin composition and mixture and blend thereof

A technology of vinyl alcohol copolymer and resin composition, applied in the direction of synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve high gel, extruder current and pressure rise, cannot be processed or solved, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Four fluoropolymers (Example Fluoropolymers A-D) were prepared according to the invention. The fluorine-containing ethylene-vinyl alcohol copolymer (hereinafter referred to as "EVOH") resin composition of the present invention was then prepared using Example Fluoropolymers A-D. Although Example Fluoropolymers A-D were prepared according to the specific methods disclosed below, other types of fluoropolymers can be used to add to EVOH.

[0049] Example Fluoropolymer A

[0050] Example Fluoropolymer A was prepared using an autoclave as a batch reactor. The autoclave has an internal volume of about 20 L and is equipped with an electromagnetic induction stirrer. Fully fill the autoclave with nitrogen (N 2 ), and then filled with reduced-pressure nitrogen five times.

[0051]While reducing the pressure in the autoclave, 6960 g of deoxygenated pure water, 3204 g of 1,1,2-trichloro-1,2,2-trifluoroethane, and 3.5 g of methylcellulose were put into the autoclave. The viscosi...

Embodiment 2

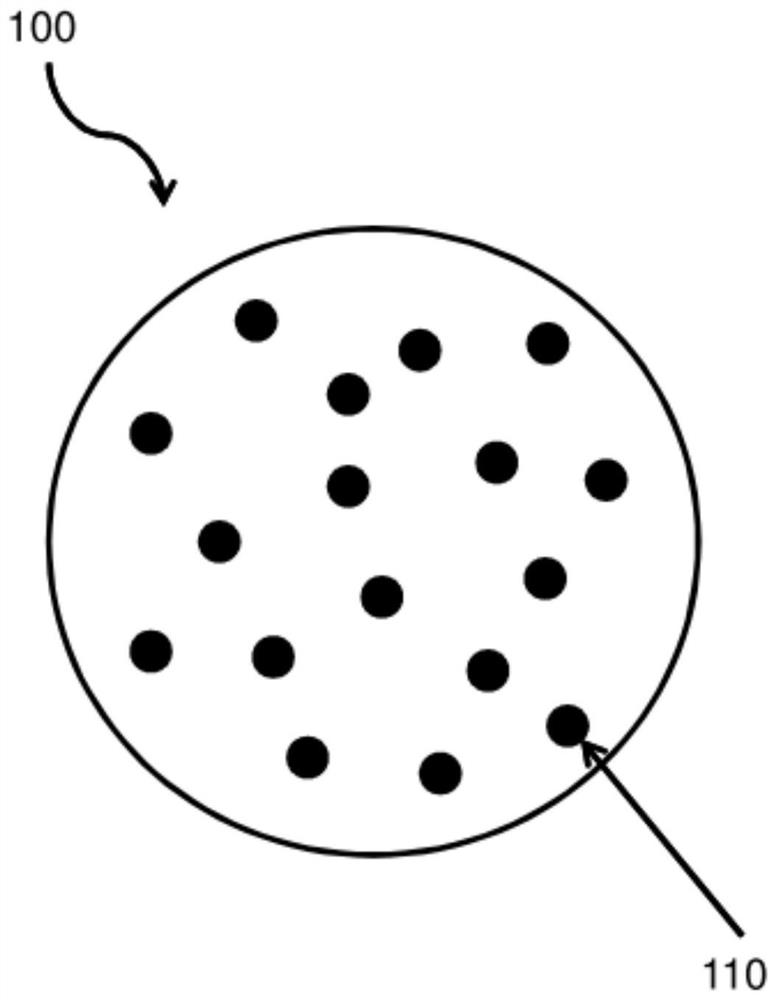

[0065] A non-limiting method of preparing fluorine-containing EVOH particles formed from the fluorine-containing EVOH resin composition is provided below. According to methods similar to those disclosed below, 16 non-limiting example EVOH resin compositions (Examples EVOH 1-16) and 4 comparative example EVOH resin compositions (Comparative Example EVOH 1-4) with fluorine particles were prepared. ). However, the specific methods for preparing Example EVOH 1-16 and Comparative Example EVOH 1-4 will generally differ in one or more respects from the methods disclosed below.

[0066] An ethylene-vinyl acetate copolymer (hereinafter referred to as "EVAC") with an ethylene content of 29 mole% was saponified to a saponification degree of 99.5% to prepare EVOH polymer. Subsequently, EVOH was dissolved in a solution containing methanol and water (70:30 ratio). After that, the EVOH solid content of the solution was 41 wt.%, and the solution was placed at 60°C.

[0067] Then the aforem...

Embodiment 3

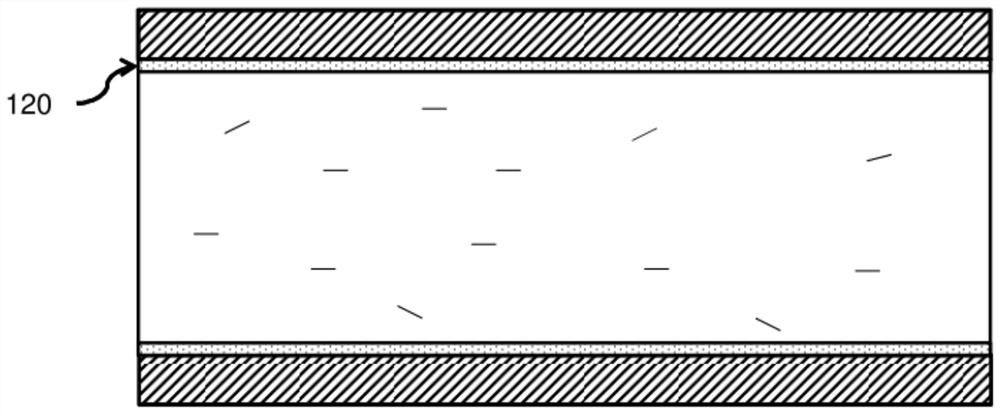

[0072] Films were formed using Example EVOH particles 1 to 16, respectively, according to the methods described below. The Example EVOH particles 1-16 and Comparative Example EVOH particles 1-4 were fed into a single-layer T-die casting film extruder (optical control system MEV4) to prepare a film. The thicknesses of the films formed from Example EVOH particles 1-16 and Comparative Example EVOH particles 1-4 were each 20 μm. The temperature of the extruder was set at 220°C, and the temperature of the mold (ie, T-shaped mold) was set at 230°C. The rotation frequency of the screw was 7 rpm (rotations / minutes).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com