Ink composition and method or printing ink

An ink composition and composition technology, applied in the direction of ink, printing, printing machine, etc., can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

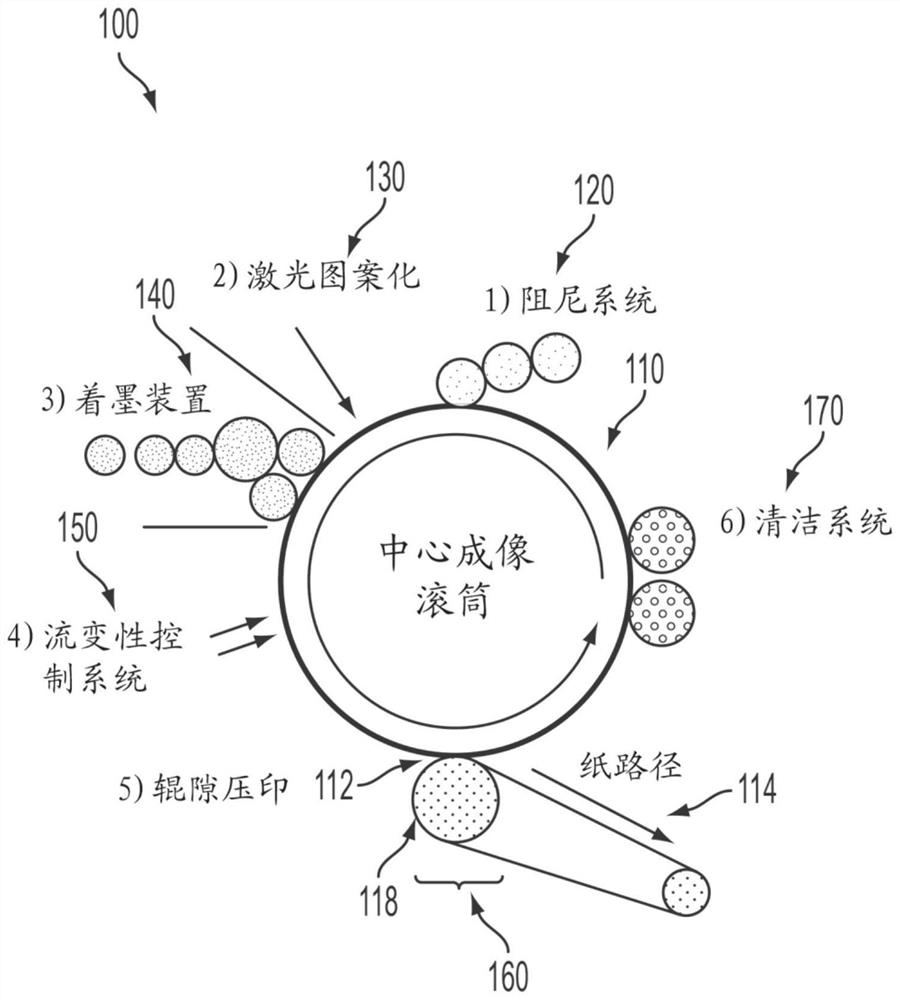

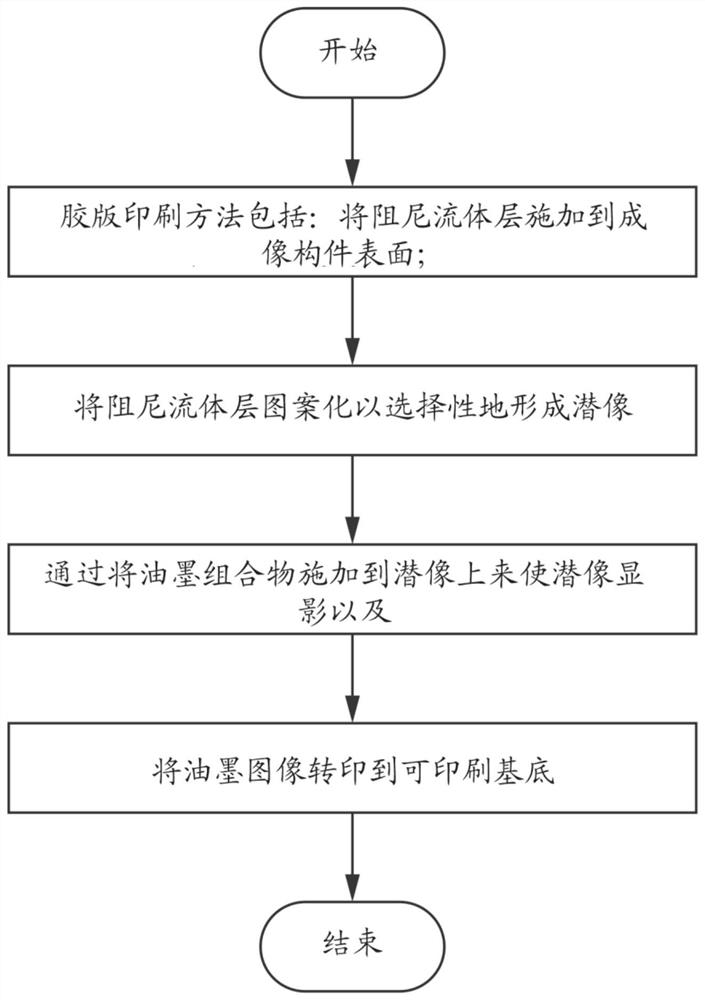

Method used

Image

Examples

Embodiment 1

[0115] Example 1: Synthesis of Highly Sulfonated Polyester (7.5 wt% Sulfonated)

[0116] A 5 gallon Parr reactor equipped with a mechanical stirrer, distillation apparatus and bottom drain valve was charged with dimethyl terephthalate (3.492 Kg), dimethyl-5-sulfoisophthalate sodium salt (940g), 1,2-propanediol (2.9kg), diethylene glycol (449g) and FASCAT 4100 (7.2g). The mixture was heated to 120°C under nitrogen flow (3 SCFH), after which stirring was started at 50 rpm. The mixture was then heated at 0.5°C / min for the next two hours until a temperature of 180°C was reached, during which time methanol by-product was collected in the distillation receiver. The mixture was then heated at 0.25°C / min until a temperature of 210°C was reached, during which time methanol and excess 1,2-propanediol were collected in the distillation receiver. Vacuum was then gradually applied until 4.4 mm-Hg was reached over a period of 1 hour at 210°C. The mixture was then repressurized to atmos...

Embodiment 2 to Embodiment 4

[0117] Embodiment 2 to embodiment 4: be formulated into DALI ink

[0118] Fluorescent pigments are added to the transparent matrix of water-based DALI inks in order to obtain corresponding fluorescent inks.

[0119] fluorescent ink

[0120]

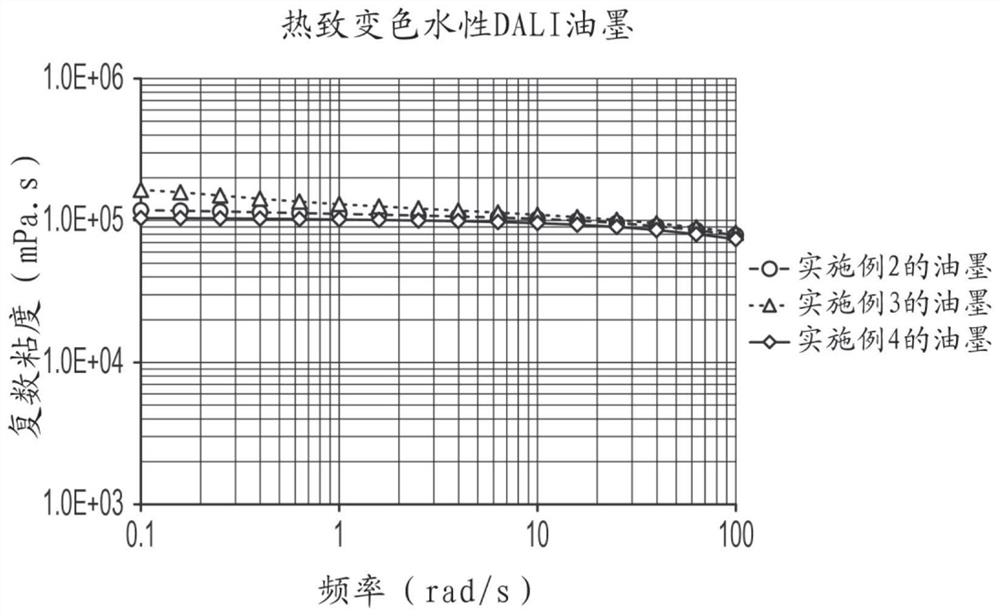

[0121] To a 100 mL beaker equipped with a heating jacket and overhead mixer was added water, sulfolane and Dynwet 800. The solution was then sheared with a Cowles blade at 600 rpm, and branched sulfonated polyester (BSPE), a sulfopolyester prepared by a method similar to that in Example 1, was added to the beaker with Onset glass transition temperature of about 55°C, number average molecular weight of 1818 g / mole, weight average molecular weight of 3315 g / mole, and softening point of about 135°C. Once the polyester is fully dispersed (about 10 minutes) at room temperature (about 23°C), the vessel is heated to 85°C-90°C and shear is continued for 10-15 minutes. The mixture was cooled to image 3 , Figure 4 and Figure 5 middle. ...

Embodiment 5

[0123] Example 5: Testing Polyurethane-Containing Fluorescent Cyan DALI Ink on Lithographic Fixtures

[0124] The ink of Example 1 was tested in a DALI surrogate printing test jig ('Mimico') to assess the efficiency of ink transfer from the blanket under typical lithographic conditions. The anilox roll was filled with ink, transferred to the blanket, and then offset printed on SterlingGloss #80 paper, followed by a second offset event and a third offset event between the new paper and the previously inked blanket to monitor possible residues on the blanket ( 'Frame sheet') residual ink. The prints were then cured in an oven at 100°C for 5 minutes.

[0125] Figure 5 The offset printing results of the ink of Example 2 are shown. Although difficult to see due to the clear coat, the sample showed good ink transfer with no residual ink observed on the "frame" sheet. The stencil section of the print was probed with UV light and no ink residue was detected. The black that app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com