Lap joint injection molding type connecting assembly and steel bar truss floor support plate

A technology for connecting components and steel trusses, which is applied to floors, building components, buildings, etc. It can solve the problems that the bottom of the floor cannot meet the acceptance criteria, affect the appearance of the bottom of the floor, increase the deformation of the bottom of the bottom form, and improve the disassembly efficiency. , good flatness of the bottom of the board, and the effect of reducing the difficulty of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

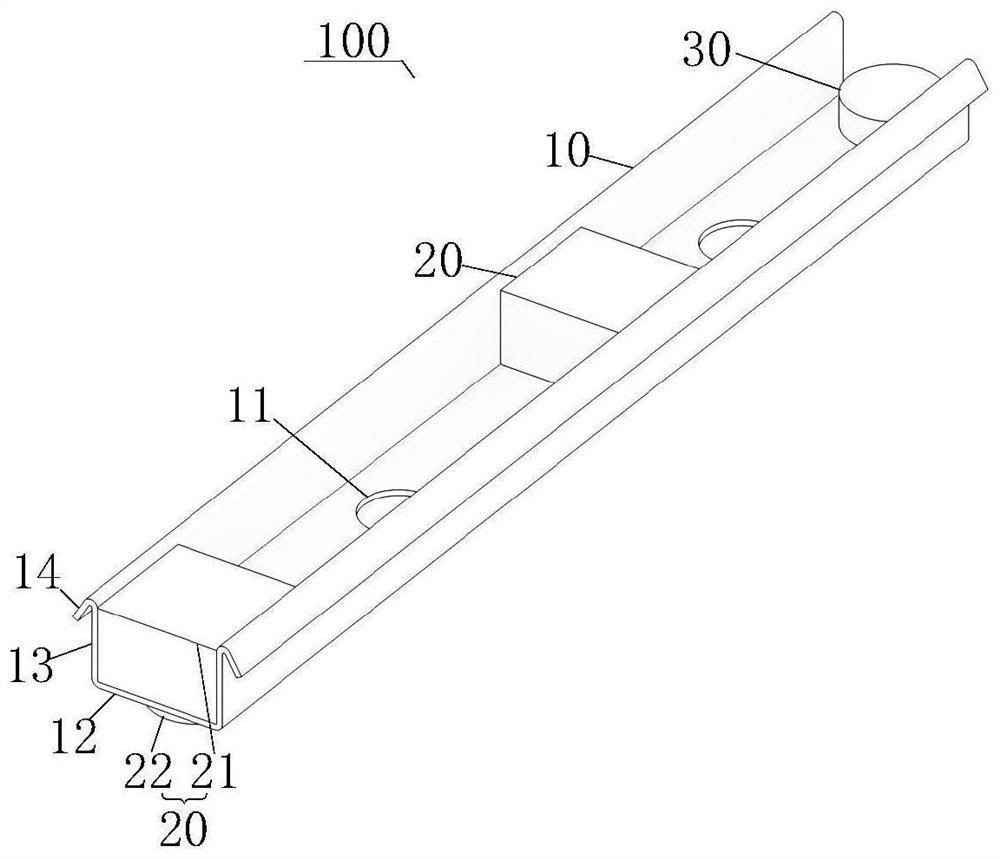

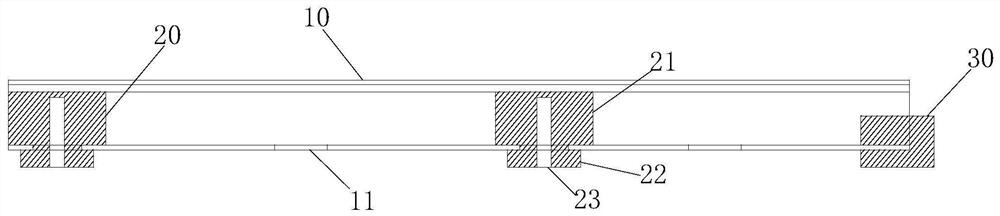

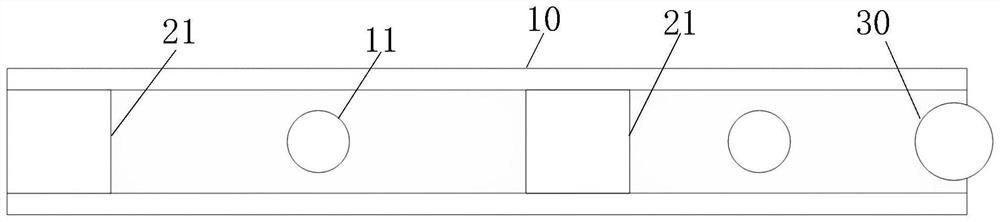

[0061] figure 1 It is a three-dimensional structural schematic diagram of an overlapping injection molding connection assembly in an embodiment of the present invention, figure 2 It is a schematic cross-sectional structure diagram of an overlapping injection molding connection assembly in an embodiment of the present invention, such as figure 1 and figure 2 shown.

[0062] An embodiment of the present invention provides an overlapping injection molding connection assembly 100 , including: a connecting piece 10 , a bridging piece 30 and a supporting piece 20 . Wherein, the connector 10 has a first surface and a second surface opposite to each other, and has a mounting hole 11 penetrating through the first surface and the second surface. by figure 1 and figure 2 Take the orientation in , as an example, the first side is the upward side, and the second side is the downward side.

[0063] combine figure 1 and figure 2 , see Figure 3 to Figure 5 , the supporting membe...

Embodiment 2

[0114] On the basis of Example 1, combined with Figure 6 , see Figure 11 and Figure 12 Correspondingly, the embodiment of the present invention also provides a reinforced truss floor deck, including: a floor deck body 200 , a plurality of rows of overlapping connection assemblies 100 and a steel truss 300 .

[0115] Wherein, each row of overlapping connecting assemblies 100 includes a plurality of overlapping connecting assemblies 100 arranged at intervals. The overlapping connection assembly 100 can be realized by the overlapping connection assembly 100 described in the embodiments. Specifically, see Figure 1 to Figure 5 , The overlapping connection assembly 100 includes: a connecting piece 10 , a connecting piece 30 and a supporting piece 20 . The connector 10 has a first surface and a second surface opposite to each other, and has a mounting hole 11 passing through the first surface and the second surface. The supporting member 20 is passed through the mounting hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com