Dual-sensitization high-sensitivity FBG temperature sensor and manufacturing method thereof

A temperature sensor, high-sensitivity technology, used in thermometers, thermometers, instruments, etc. with physical/chemical changes, it can solve the problems of long reaction time, poor sensitivity, and inability to achieve rapid and accurate measurement, and achieve response The effect of short time, long service life and rapid response to external temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

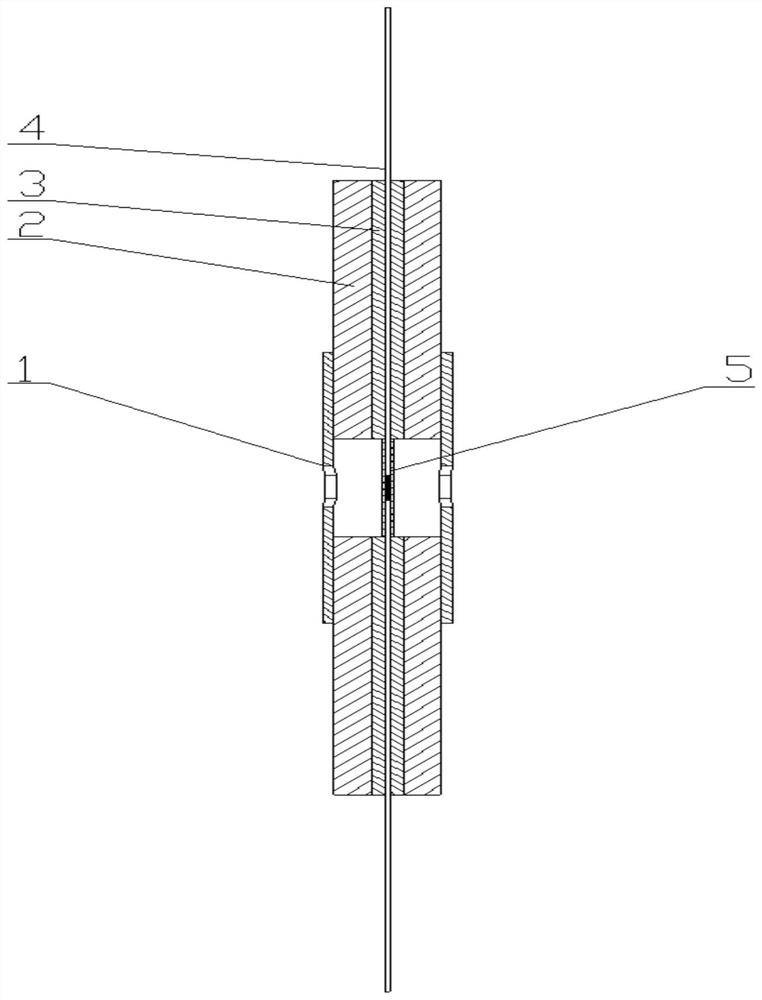

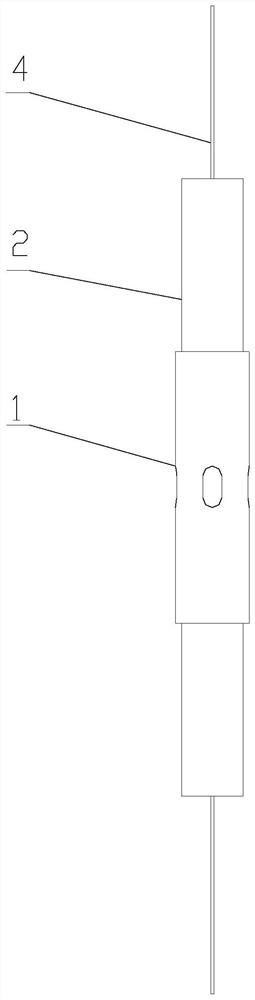

[0031] see figure 1 with figure 2 , the embodiment of the present invention includes a metal shell 1, a metal pipe 2, a thermally conductive colloid 3, an optical fiber grating 4, and a high thermal expansion coefficient colloid 5; the thermally conductive colloid 3 adopts PDMS glue or epoxy resin glue;

[0032] The metal shell 1 is cylindrical with thermal conductivity; the metal tube 2 has thermal conductivity, and the outer diameter of the metal tube 2 is smaller than the inner diameter of the metal shell 1;

[0033] Two metal tubes 2 are inserted into the metal shell 1 from both ends of the metal shell 1 and bonded and nested on the inner wall of the metal shell 1 by the thermally conductive colloid 3, and the gap between the metal tube 2 and the metal shell 1 is filled with the thermally conductive colloid 3 The distance betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com