Rotary machine rotating speed fluctuation keyless phase order tracking method

A technology of rotational speed fluctuation and rotating machinery, applied in the measurement of ultrasonic/sonic/infrasonic waves, testing of machines/structural components, measuring devices, etc., it can solve the problems of inability to extract time-domain waveforms and poor calculation accuracy, so as to reduce the cost of fault diagnosis. , the effect of obvious amplitude and high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

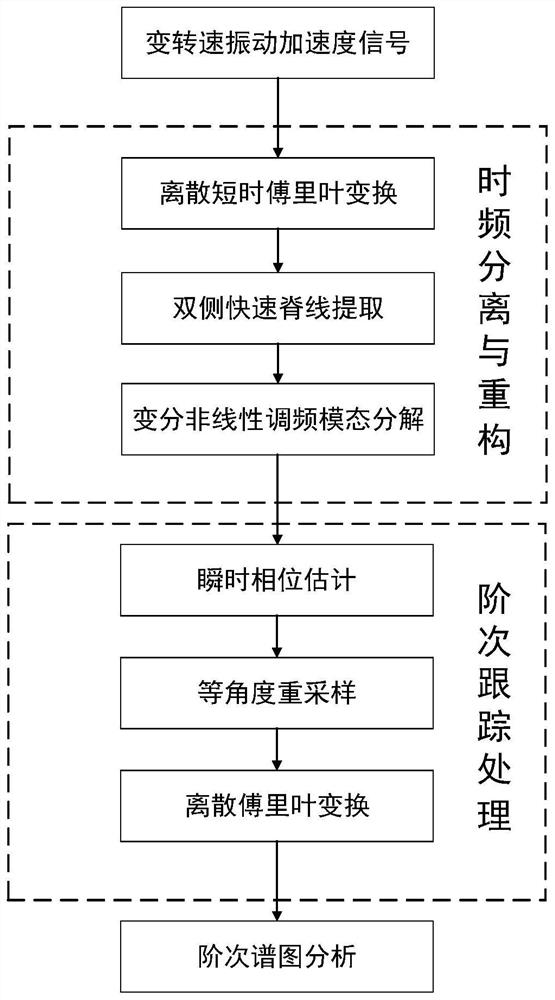

[0150] like figure 1 As shown, it is a keyless phase order tracking method for the speed fluctuation of rotating machinery. Assuming that the variable speed vibration signal is x(t), the method specifically includes the following steps:

[0151] Step 1: Install a vibration acceleration sensor near the rotating machinery to collect the vibration acceleration signal x(t) during variable speed operation;

[0152] Step 2: Perform discrete short-time Fourier transform (STFT) on the collected signal to obtain the time-frequency expression TFR(t,f), which specifically includes the following steps:

[0153] Step 201: Set the window function length N W and Fourier points L F , to construct the corresponding window function g(t):

[0154]

[0155] In the formula, σ is the window function coefficient;

[0156] Step 202: Perform discrete short-time Fourier transform (STFT) on the variable speed vibration acceleration signal x(t) to obtain the time-frequency expression TFR(t,f):

...

Embodiment 2

[0241] like figure 2 As shown, it is a second embodiment of the keyless phase order tracking technology for rotational speed fluctuations of rotating machinery. The vibration simulation signal x(t) of the gearbox is constructed, and the instantaneous rotational frequency of the reference shaft is:

[0242] f(t)=[500+1000*sin(2π·0.1t)] / 50 (40)

[0243] The amplitude modulation and phase modulation functions caused by the fault are:

[0244]

[0245] The gearbox vibration signal x(t) is:

[0246]

[0247] The concrete implementation result of this embodiment is as follows:

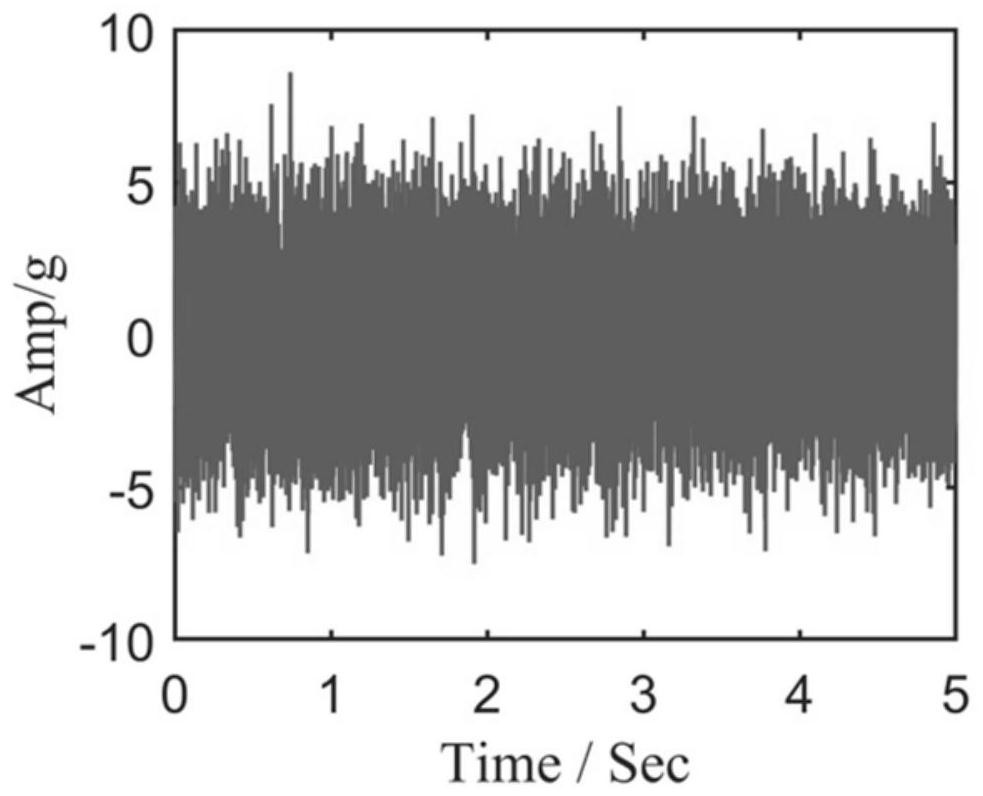

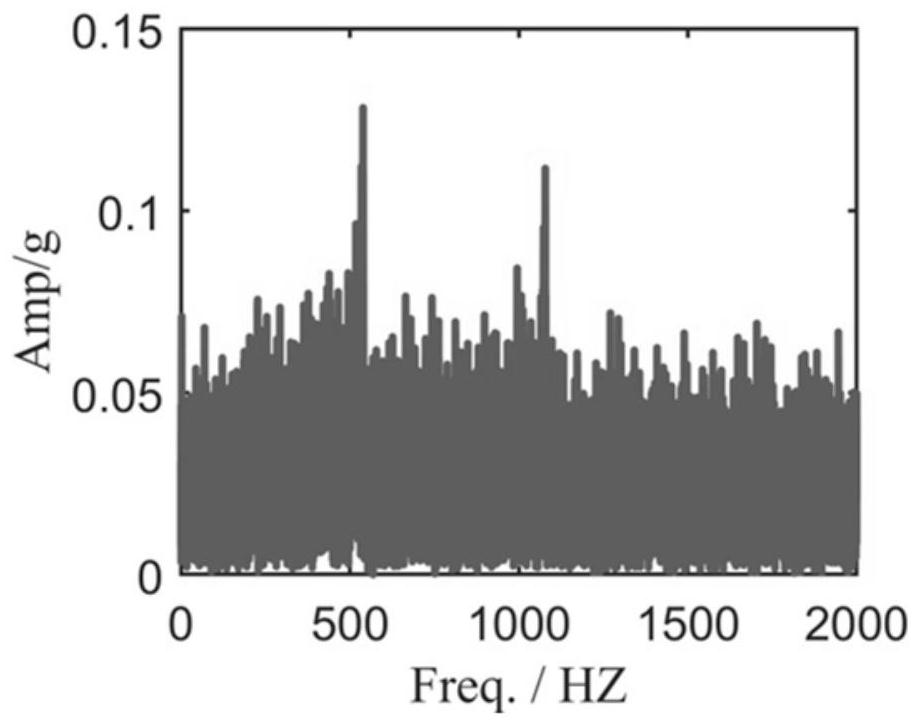

[0248] Set the basic parameters of the variable speed vibration signal: the highest meshing frequency order K=2, the number of faulty gear teeth N=16, the amplitude of the kth order meshing frequency X k = 1, initial phase Signal sampling frequency Fs=4000Hz, sampling time t=5s, signal-to-noise ratio SNR=-6dB.

[0249] Using the fast Fourier transform (FFT) method, the gearbox vibration signal x...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com