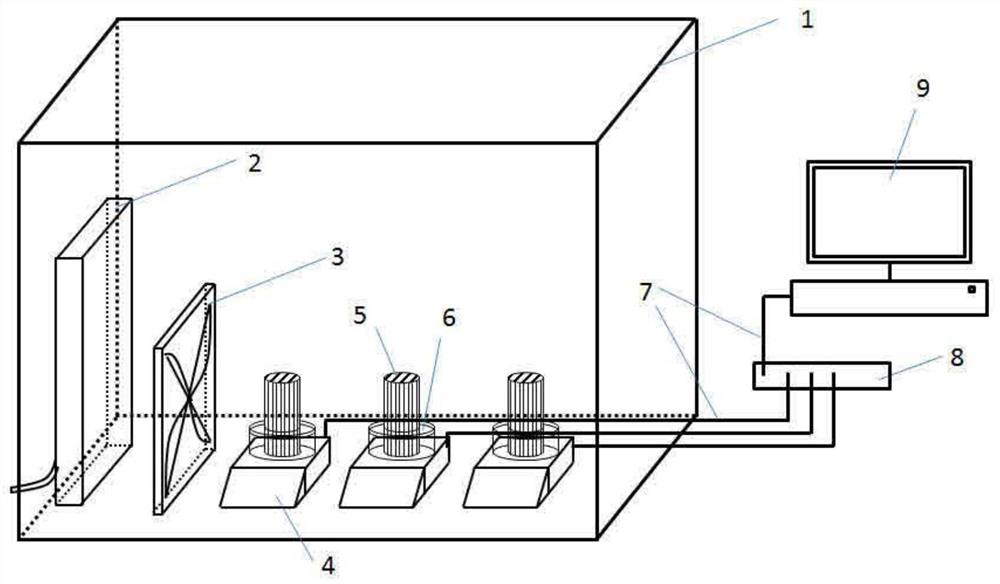

Device and method for testing evaporation rate of water passing through concrete surface under wick effect

A technology of concrete surface and evaporation rate, applied to measuring devices, weighing by removing certain components, analyzing materials, etc., can solve problems such as inconsistency in the transmission of salty moisture, avoid volatility and hysteresis, and increase test effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

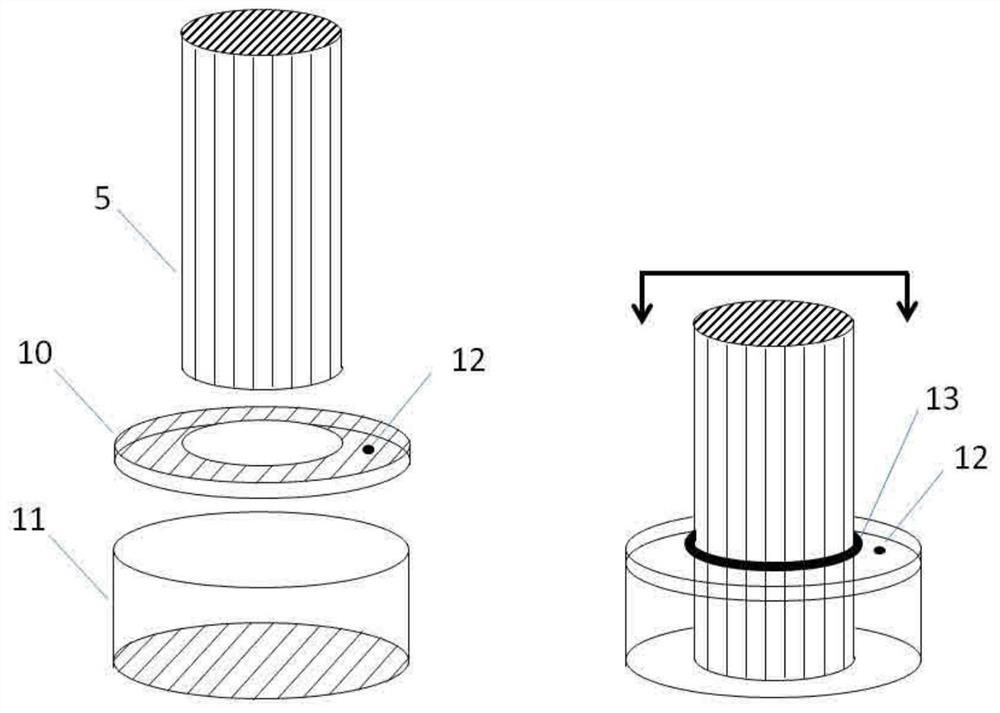

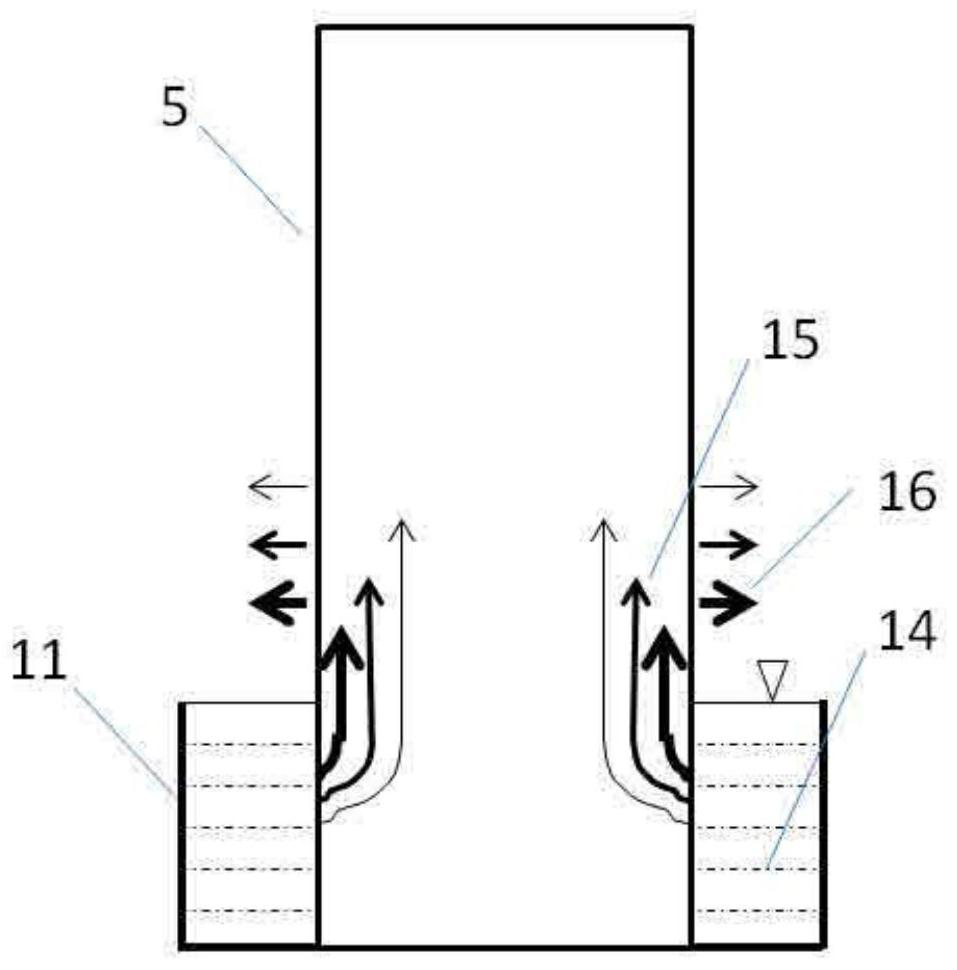

Method used

Image

Examples

Embodiment

[0067] Table 1 Mixing ratio for water evaporation test

[0068]

[0069]As shown in Table 1, four types of concrete were designed, and the two water-binder ratios of 0.55 and 0.45 were compared, whether mineral admixtures (25% fly ash FA and 15% mineral powder SL) were added, and mineral powder was added at the same time. The effect of admixtures and erosive medium inhibitors or preservatives (TIA, RMA produced by Jiangsu Subote New Materials Co., Ltd.) on the water evaporation rate. Form a concrete test block of 175mm×185mm×150mm, and after curing for 28 days, obtain a core sample with a diameter of 75±2mm by drilling a core, dry it in an oven at 105°C for 72±2h, take it out and dry it in a drying oven for at least 24h.

[0070] Use the specific implementation method to do the described test device, test with reference to the above steps, control the ambient humidity to 40%, do not consider the influence of wind speed, and keep the external temperature at 25°C, lift the pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com