Weeding composition containing profoxydim and anilofos

A herbicidal composition and a technology of cyclofenazone are applied in the directions of herbicides, algicides, biocides, animal repellents, etc., which can solve problems such as being difficult to know and have no creativity, and achieve good control effects and herbicidal effects. The effect of broad spectrum and significant control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

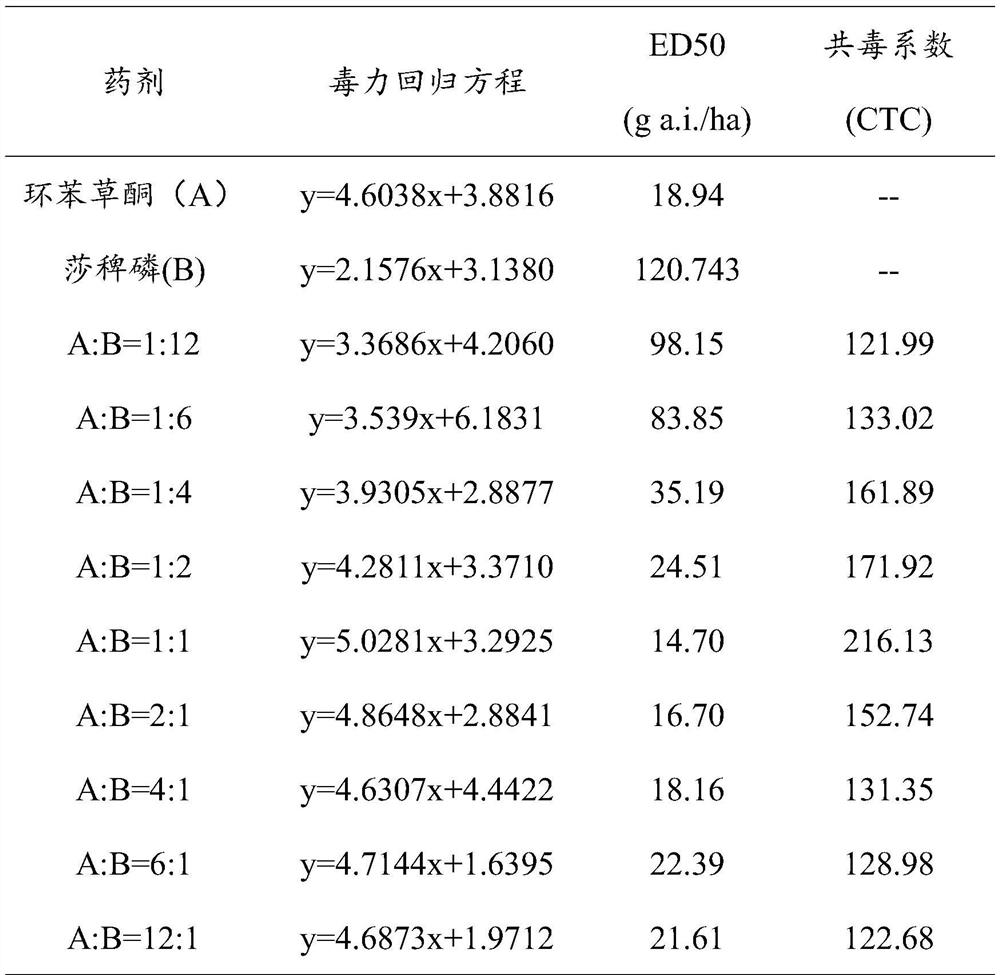

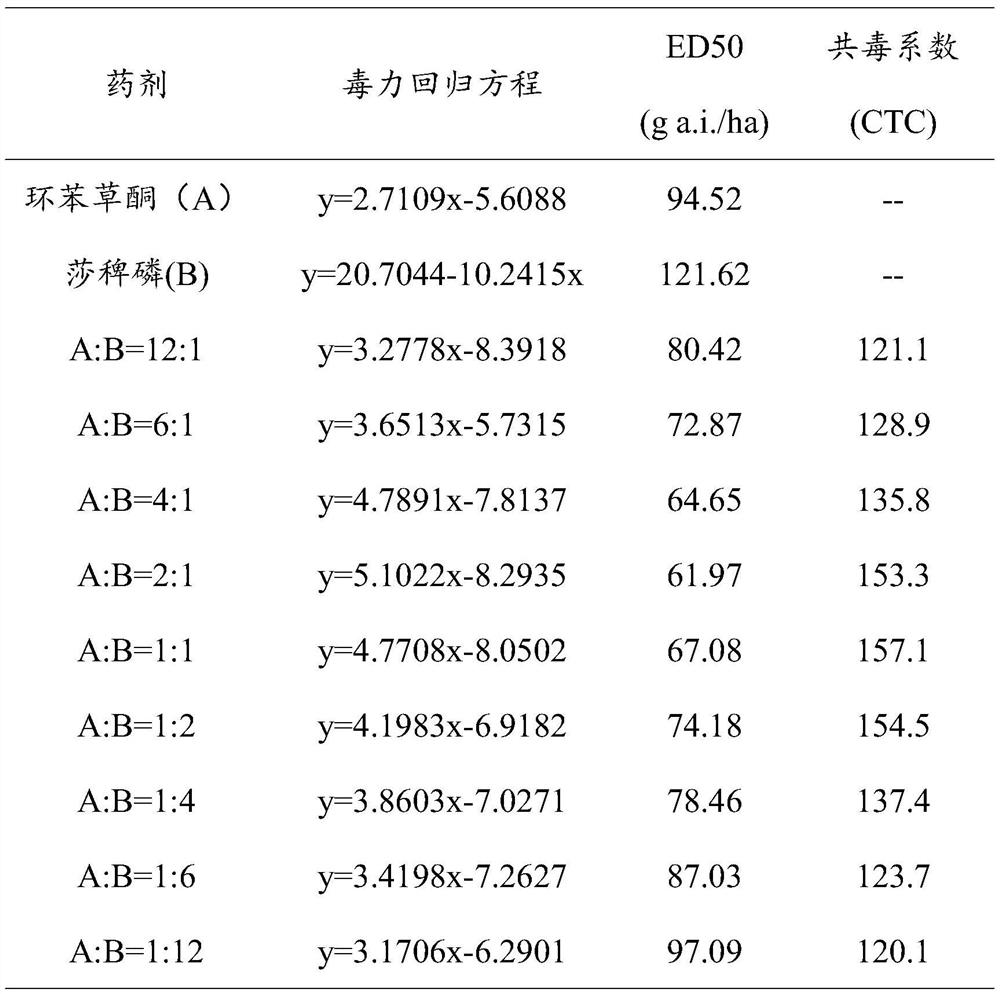

Method used

Image

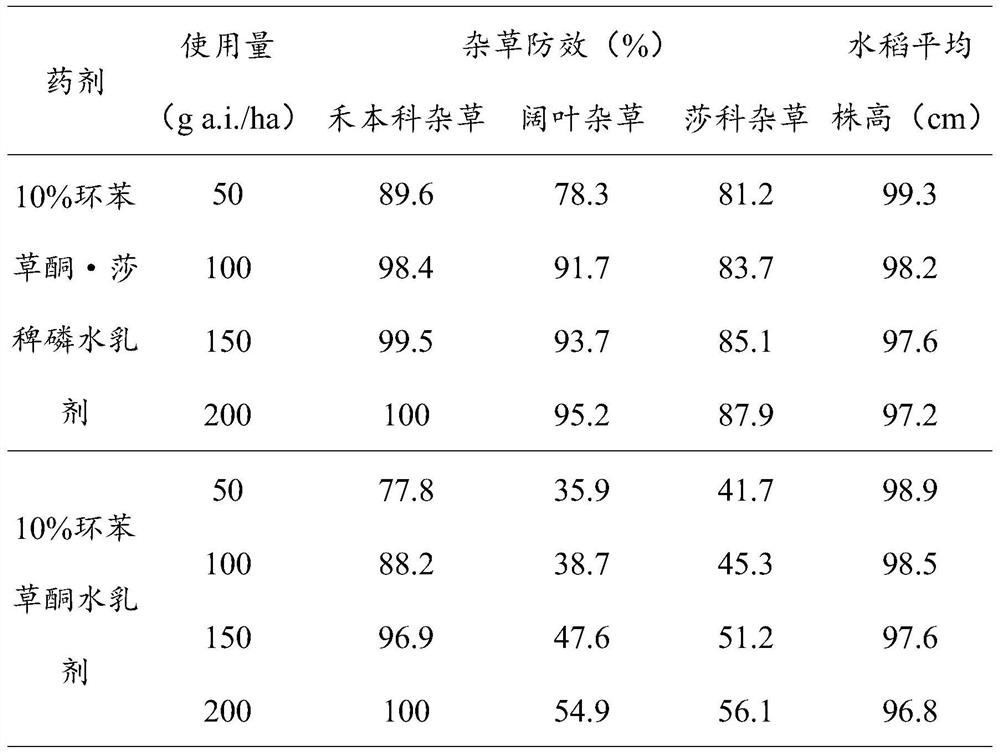

Examples

Embodiment 1

[0018] This example provides the preparation of 30% cycloclozone·sapine phosphorus water emulsion.

[0019] In terms of parts by mass, every 100 parts of cyclooxygenone-sapylphosphorus aqueous emulsion contains 6 parts of cyclooxygenone, 24 parts of saponin, 5 parts of cyclohexanone, 20 parts of tetramethylbenzene solvent, castor oil polyoxygen 3 parts of vinyl ether, 2 parts of phosphate emulsifier, 5 parts of phenol polyoxyethylene ether, 35 parts of sterile water.

[0020] Weigh each component according to the above parts by mass, and add cyclobucinone, saponin and cyclohexanone, tetramethylbenzene solvent, castor oil polyoxyethylene ether, phosphate emulsifier phenol polyoxyethylene ether, into the stirring tank , fully stirred and dissolved to form an oil phase, then added the dissolved oil phase to 35 parts of water, and at the same time started the shear emulsification disperser, and sheared and emulsified into a uniform milky white liquid, which is 30% Cyclobuzone·Sapi...

Embodiment 2

[0022] This example provides the preparation of 30% cyclooxygenone·saponin emulsifiable concentrate.

[0023] In terms of parts by mass, every 100 parts of Cyclotrione·Sabylphos emulsifiable concentrate contains 24 parts of Cyclobufenone, 6 parts of Sabinphosphorus, 15 parts of Nongru 400#, 35 parts of N-methylpyrrolidone, and industrial vegetable oil 17.5 parts, 2.5 parts of epichlorohydrin.

[0024] Weigh each component according to the above-mentioned parts by mass, add saponin and cyclazone into N-methylpyrrolidone, mix well, add industrial vegetable oil, agricultural milk 400# and epichlorohydrin in sequence, and stir well to form Uniform and transparent oily liquid, that is, 30% cyclooxygen-sapylphosphorus emulsifiable concentrate.

Embodiment 3

[0026] This example provides the preparation of 30% Cycloclozone·Sabenphos water-dispersible granules.

[0027] In terms of parts by mass, every 100 parts of cyclobufenone·sapylphosphorus water-dispersible granule contains 2.31 parts of cyclobufenone, 27.69 parts of saponinphosphorus, 2 parts of lignocarbon sulfonate, lauryl sulfate 3 parts of sodium, 5 parts of sodium sulfate, 5 parts of polyethylene glycol, 55 parts of kaolin.

[0028] Weigh each component according to the above parts by mass, put the material into the mixer and mix evenly, then pulverize it through the jet mill, pass through a 600-mesh standard sieve, add it into the kneader to knead into a plastic material, and finally put the material into extrusion granulation Squeeze and granulate in the machine, dry and sieve after granulation to obtain 30% cycloclozone·sapine phosphorus water-dispersible granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com