Shell processing system filled with Pu'er tea

A processing system and technology of Pu'er tea, which is applied in the field of fruit shell processing system for filling Pu'er tea, can solve the problems of low manual processing efficiency, inability to obtain market benefits, time-consuming and energy-consuming, and save manpower and time , ingenious design, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

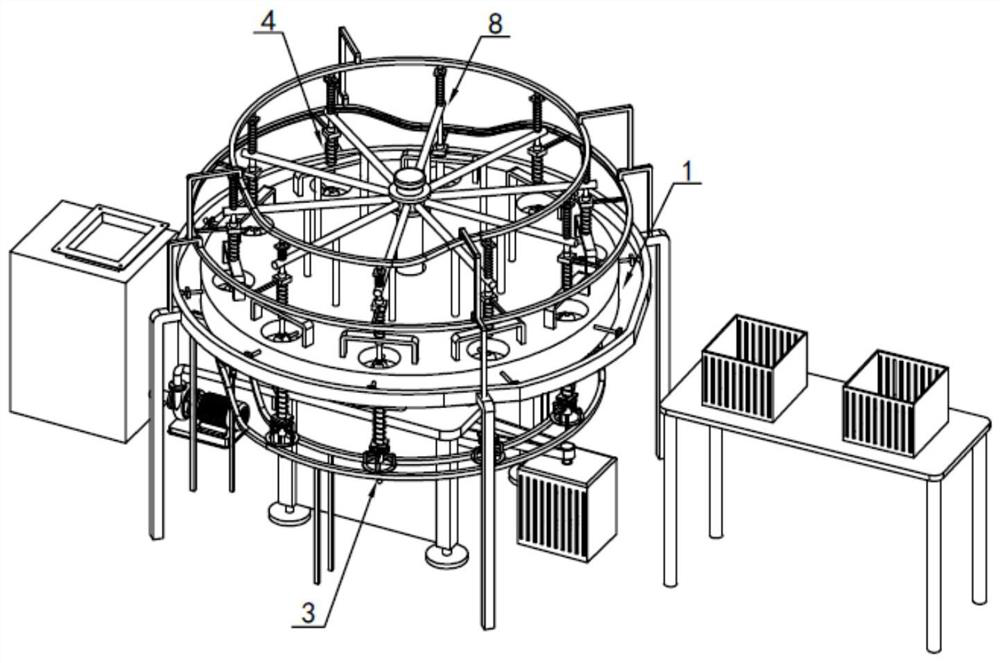

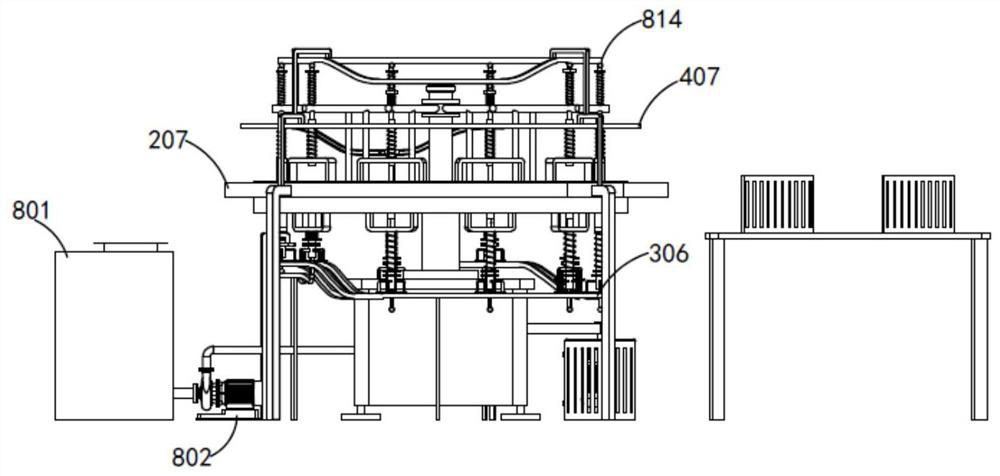

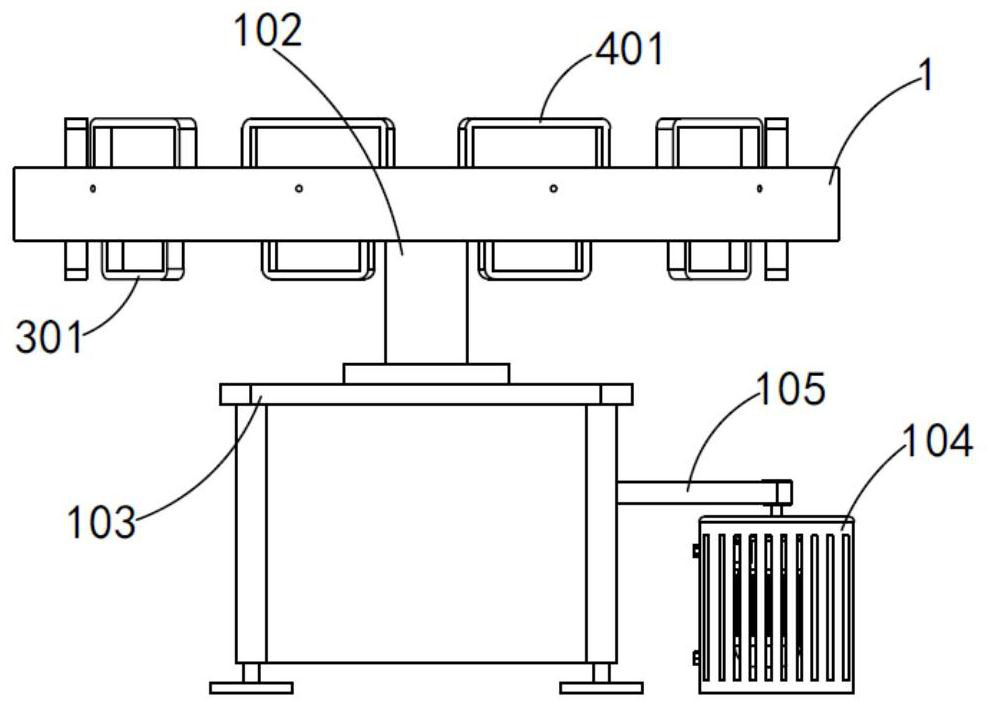

[0043] Such as Figure 1 to Figure 19 As shown, a fruit shell processing system for filling Pu-erh tea includes a rotating disk 1, and the rotating disk 1 is provided with a plurality of bearing grooves 101 distributed in a circular array, and the bearing grooves 101 are used to limit and carry a single lime , the bearing groove 101 is provided with a clamping assembly 2, and the clamping assembly 2 is used to fix and clamp a single lime in the bearing groove 101 during the rotation process, and the corresponding setting directly below the bearing groove 101 There is a capping assembly 3 fixed on the bottom of the rotating disk 1. During the rotation, the capping assembly 3 digs the caps for the clamped limes by lifting up vertically. Correspondingly, there is an ejection assembly 4 fixed on the top of the rotating disk 1, and the ejection assembly 4 pushes the lime caps separated from the digging assembly 3 downwards by vertically pressing downwards during the rotation proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com