Movable flue gas deacidification and desulfurization device and use method thereof

A desulfurization device and mobile technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of easy hardening, affecting the service life of the device, and exceeding the standard of flue gas emissions, so as to improve economic benefits and increase stability. The effect of prolonging the practical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

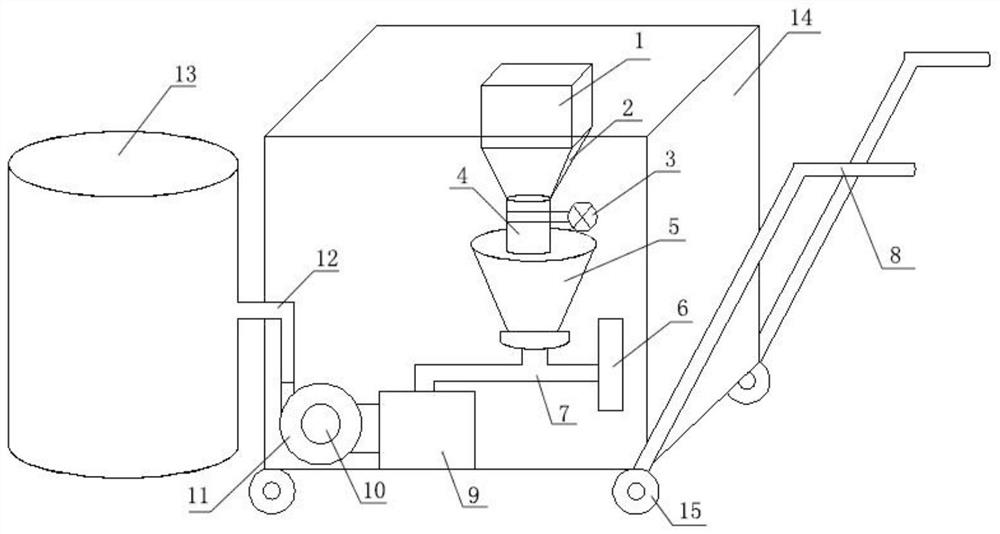

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention is described below through specific embodiments shown in the accompanying drawings. It should be understood, however, that these descriptions are exemplary only and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention. Embodiment 1: as figure 1 As shown, a kind of mobile flue gas deacidification and desulfurization device of the present invention comprises sodium bicarbonate spraying device and mobile casing 14, and described baking soda spraying device comprises the feeding part that connects in sequence, weighing part, grinding part and conveying part;

[0028] The feeding part includes a silo 1 for storing baking soda, and a pneumatic valve 3 for controlling feeding is ar...

Embodiment 2

[0033] Embodiment 2: A method for using a flue gas deacidification and desulfurization device in a waste incineration power plant, using the mobile flue gas deacidification and desulfurization device system in Embodiment 1, comprising the following steps:

[0034] 1: Conveying and grinding: choose 60-mesh baking soda and put it into the silo, transport it to the grinder for grinding through the conveying fan, and grind it into 700 mesh after being ground by the grinder;

[0035] 2. Measuring and weighing: adjust the real-time flow rate of the weightless feeder according to the amount of garbage incinerated in the furnace, automatically set the frequency of the corresponding conveying fan, and control the input of baking soda to 4.2kg / ton of garbage in the furnace;

[0036] 3. Injection reaction and detection: Under the action of the blower, after grinding, the baking soda is blown into the reaction tower by the wind for deacidification and desulfurization reaction.

[0037] Af...

Embodiment 3

[0038] Embodiment 3: A method for using a flue gas deacidification and desulfurization device in a waste incineration power plant, using the mobile flue gas deacidification and desulfurization device system in Embodiment 1, which is different from that in Embodiment 2:

[0039] 1: Conveying and grinding: select 60-mesh baking soda into the silo, transport it to the grinder for grinding through the conveying fan, and grind it into 850 mesh after being ground by the grinder, and control the input amount of baking soda to be 4.2kg / ton into the furnace garbage;

[0040] After the above reaction, the concentration of HCl in the flue gas is 1-7mg / m 3 , SO 2 The average concentration is 1mg / m 3 , the index is far lower than the national standard GB18485-2014 standard and the European Union 2010 / 75 / EU standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com