Equipment for preparing polyglycerol isomeric fatty acid ester, and operation method thereof

A technology of fatty acid ester and operation method, applied in the directions of carboxylate preparation, separation method, chemical instrument and method, etc., can solve problems such as low production efficiency, achieve short reaction time, improve product purity, low ash content and acid value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

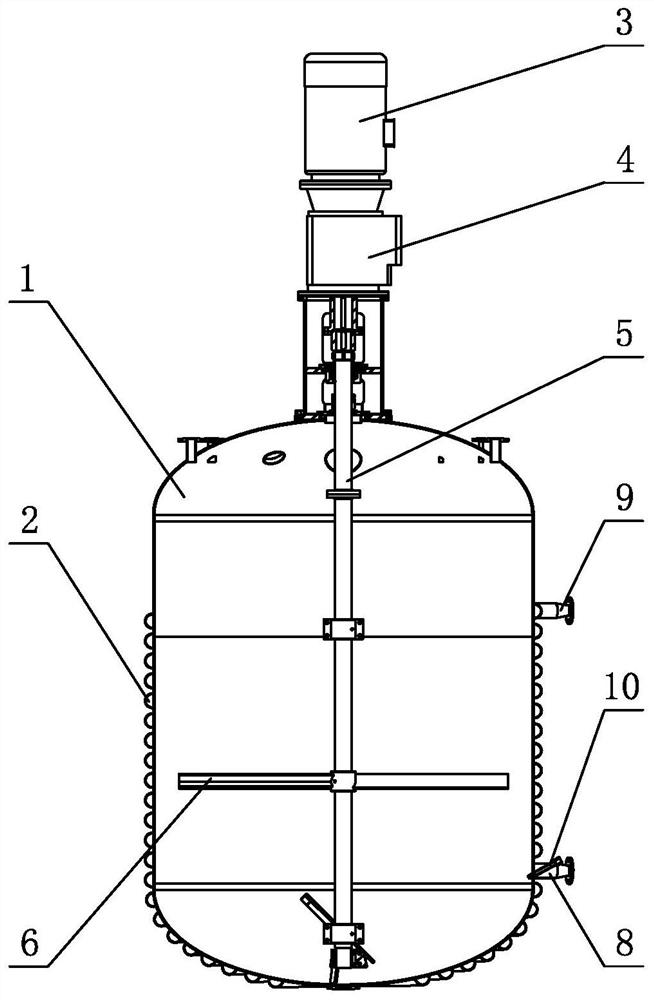

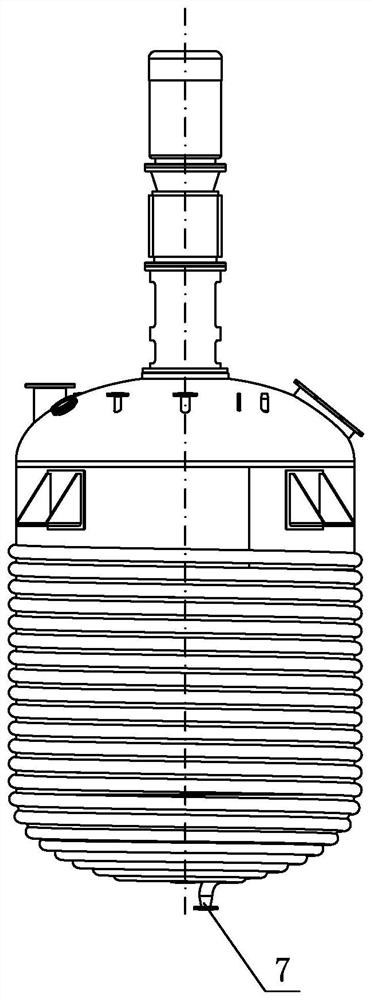

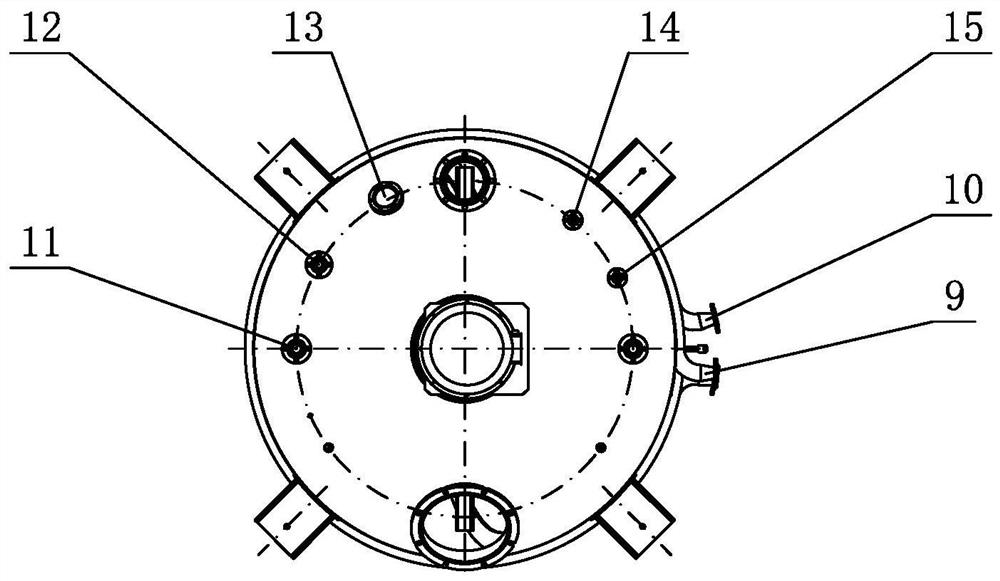

[0061] see Figure 1-Figure 7 and Figure 12 , the equipment for making polyglycerol isomeric fatty acid esters includes a reactor 1 with stirring blades, a heating device is arranged on the outer wall of the reactor 1, and the heating device includes a The heat-conducting spiral tube 2 or the heating jacket on the outer wall, the heat-conducting spiral tube 2 or the heating jacket is wound from the bottom of the reactor to the middle and upper part of the reactor 1, wherein the first heat-conducting oil inlet pipe 7 and the heat-conducting spiral tube 2 Or the lowest part of the heating jacket is connected, the second heat-conducting oil inlet pipe 8 is connected with the middle part of the heat-conducting spiral pipe 2 or the heating jacket, and the heat-conducting oil outlet pipe 9 is connected with the highest point of the heat-conducting spiral pipe 2 or the heating jacket .

[0062] The upper part of the reaction kettle 1 is provided with a first feeding port 14 and a ...

no. 2 example

[0098] see Figure 8 and Figure 13 , in this embodiment, the polyglycerol is polyglycerol-3, and when the molar ratio of polyglycerol-3 to isostearic acid is 1:1.5-2.2, polyglycerol-3 diisostearate is obtained. Preferably, the molar ratio of polyglycerol-3 to isostearic acid is 1:1.56-2.2. The dosage of the food-grade antioxidant is 0.54%-3.25% of the sum of the mass of polyglycerol and the mass of the basic catalyst.

[0099] After the mixing reaction, the specific indicators of the obtained polyglycerol-3 diisostearate are shown in Table 3.

[0100] Table three

[0101]

[0102] The color of polyglyceryl-3 diisostearate can be found in Figure 8 .

[0103] Next, the polyglycerol-3 diisostearate obtained above is carried out the detection of the two functional groups of ester group and hydroxyl group by infrared chromatography, and the detection results are shown in Figure 13 .

[0104] See Table 2 for the analysis of the test results.

[0105] Refer to the first...

no. 3 example

[0107] see Figure 9 and Figure 14 , when the polyglycerol is polyglycerol-10, and the molar ratio of polyglycerol-10 to isostearic acid is 1:1.5-2.2, polyglycerol-10 diisostearate is obtained. Preferably, the molar ratio of polyglycerol-10 to isostearic acid is 1:1.55-2.15. The dosage of the food-grade antioxidant is 0.83%-4.62% of the sum of the mass of polyglycerol and the mass of the basic catalyst.

[0108] After the mixing reaction, the specific indicators of the obtained polyglycerol-10 diisostearate are shown in Table 5.

[0109] Table four

[0110]

[0111] The last column of table five is the specific index of the same product of Nikko Chemical Trading (Shanghai) Co., Ltd., can basically draw from Table 4, the specific index that the present invention obtains polyglycerol-10 diisostearate is the same as that of Nikko Chemical Trading The specific indicators of the same products of (Shanghai) Co., Ltd. are basically the same.

[0112] The color of polyglycery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com