Casting method of large two-plate type injection molding machine mold plate casting

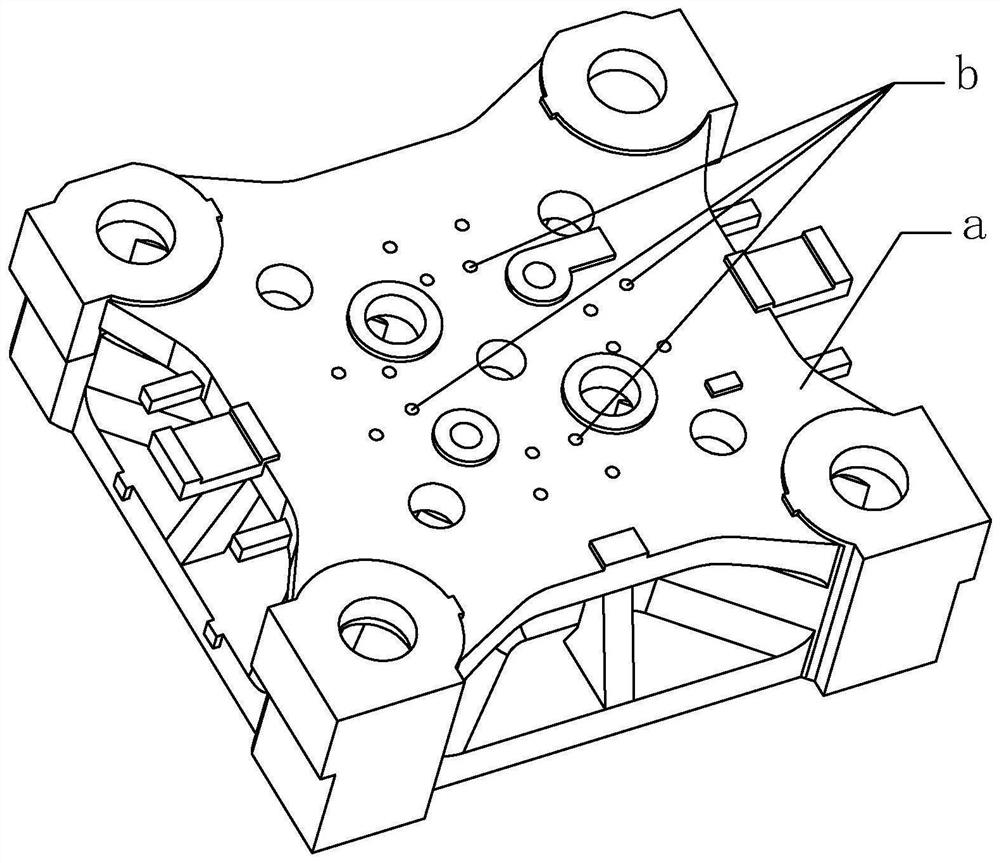

A two-plate, injection molding machine technology, used in casting molding equipment, molds, cores, etc., can solve the problems of loss of template parallelism, injection repeatability, inability to meet high-precision mold production, and casting blowhole defects. , to improve the cooling effect, facilitate adjustment, and reduce shrinkage cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] (1) The raw material of following mass percentage is taken: 40% of pig iron, steel scrap 35%, 25% of returned charge, carburizer: 0.9% of the total amount of pig iron, scrap steel, returned charge;

[0095] (2) Put all the pig iron, steel scrap, recycled material and recarburizer into the smelting furnace, heat to melt the furnace material, add FeSi75-C ferrosilicon after the furnace material is melted, the amount of ferrosilicon added is pig iron, scrap steel and recycled 0.80% of the total mass of the charge to obtain the original molten iron, and continue to heat the original molten iron to 1440°C; the composition and mass percentage of the obtained original molten iron are C 3.55%, Si 1.45%, Mn 0.20%, P 0.028% , S 0.023%, the rest is iron;

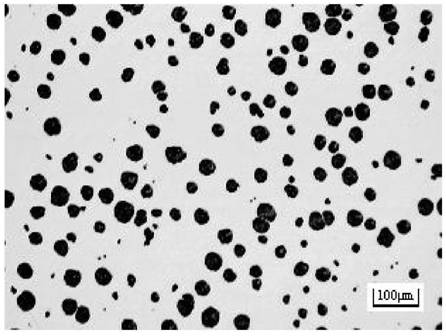

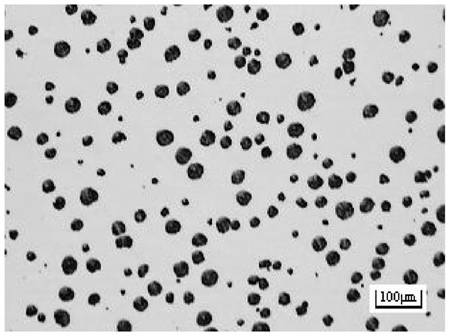

[0096] (3) Spheroidization: the spheroidization is carried out by the flushing method. The spheroidizing agent on one side of the spheroidizing bag is first added and compacted, and then 0.005% pure antimony of the original molt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com