Cooling liquid device for machining, and using method thereof

A technology of machining and coolant, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of poor cooling effect, blockage, poor material recovery, etc., to improve cooling effect, increase consumption, temperature reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

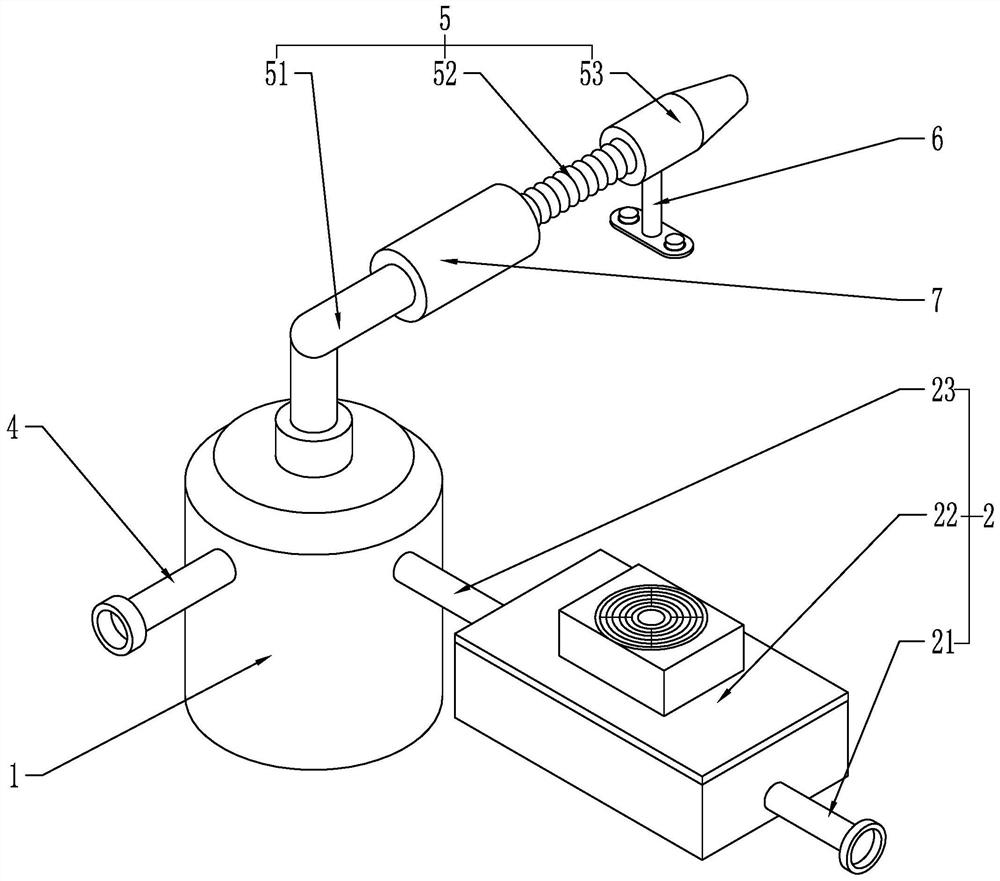

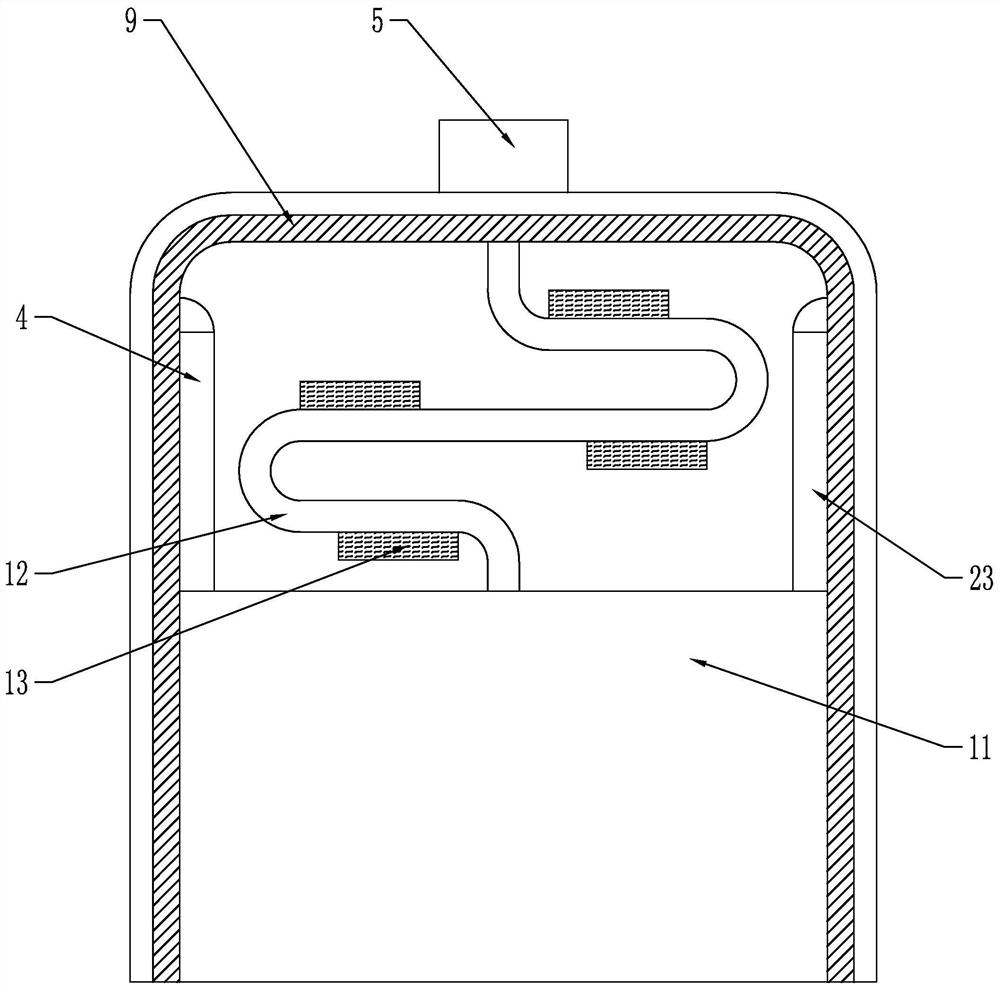

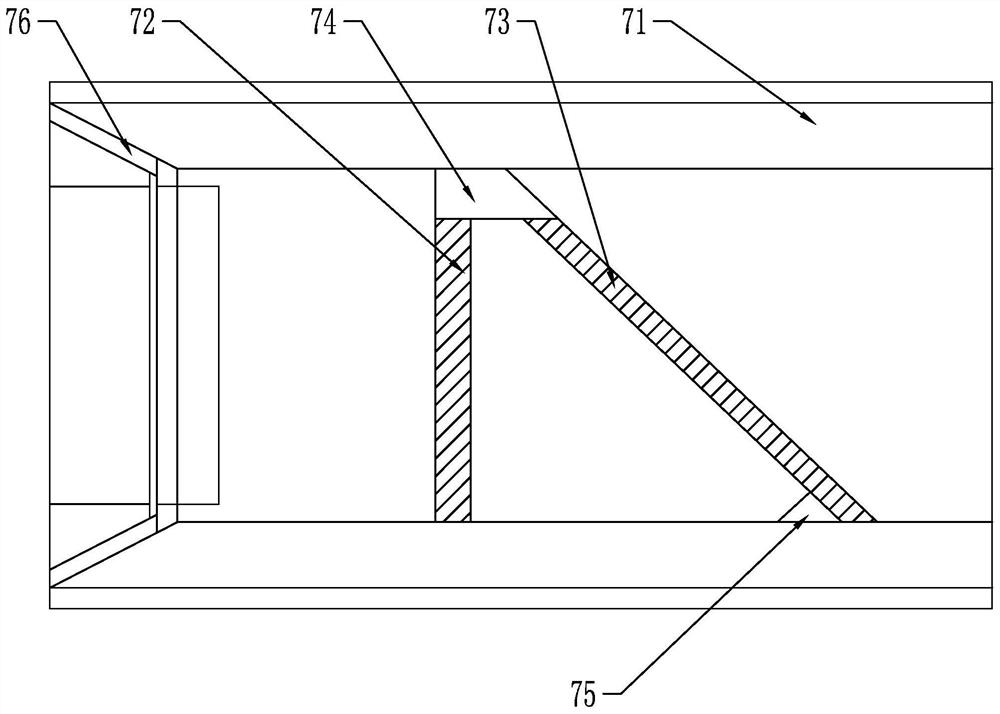

[0038] to combine Figure 1 to Figure 6 , this embodiment provides a cooling liquid device for mechanical processing, including a cooling cylinder 1 and a recovery filter device 2, a liquid storage tank 11 is provided inside the cooling cylinder 1, and a liquid replenishment pipeline 4 and a delivery pipeline 5 are externally connected to the cooling cylinder 1 and All are connected with the liquid storage tank 11, and the liquid storage tank 11 is provided with a delivery pump, and the liquid replenishment pipeline 4 adds cooling liquid to the liquid storage tank 11, and the output end of the delivery pump is connected with the delivery pipeline 5, and the liquid storage tank 11 is connected with the delivery pump. The cooling liquid inside is output from the conveying pipe 5, and the end of the conveying pipe 5 is provided with a cooling nozzle 53, which can be sprayed on the machining position. The recovery and filtration device 2 is respectively connected to the liquid sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com