Pressure sensor packaging module

A technology of pressure sensor and molding, which is applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, instruments, measuring force, etc., can solve the problems of pressure sensor packaging process complexity, poor chip protection effect, high cost, etc., and achieve improvement Protective effect, simplify the manufacturing process, reduce the effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

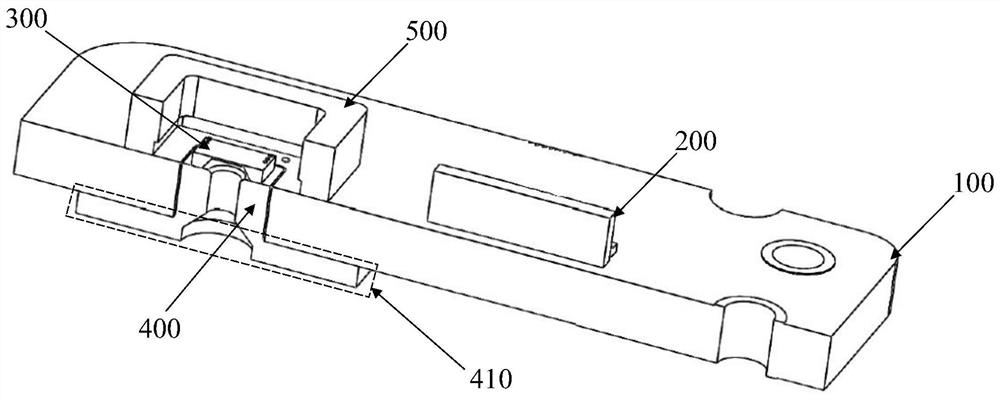

[0058] As a preferred embodiment, the pressure sensor package module further includes a frontal potting layer 310; the front surface debris layer is disposed in the protective chamber, covering the front side of the MEMS pressure sensing chip 300, The front side of the MEMS pressure sensing chip 300 is directly in contact with the external fluid atmosphere, further improving the protection effect.

[0059] Further, the inner wall of the protective frame 500 includes a swimming groove, and when the front pin sealing layer 310 is provided, the liquid potting glue is larger due to the large surface tension, along the side of the protective frame 500. The wall is climbed up, which in turn affects the potting effect. The glue climbed may also destroy other structures on the PCB substrate 100, and the anti-climbing groove can effectively block the glue from climbing, protect other original devices, and improve the final finished product. Rate. The anti-climbing groove can be an equal hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com