Magnesium hydride solid hydrogen energy storage system and method for improving hydrogen storage and release efficiency

A magnesium hydride and hydrogen energy storage technology, applied in the production of hydrogen, reversible absorption of hydrogen, etc., can solve the problems of not focusing on the important role of temperature, and achieve the effect of increasing heat conduction, increasing reaction rate, and increasing heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

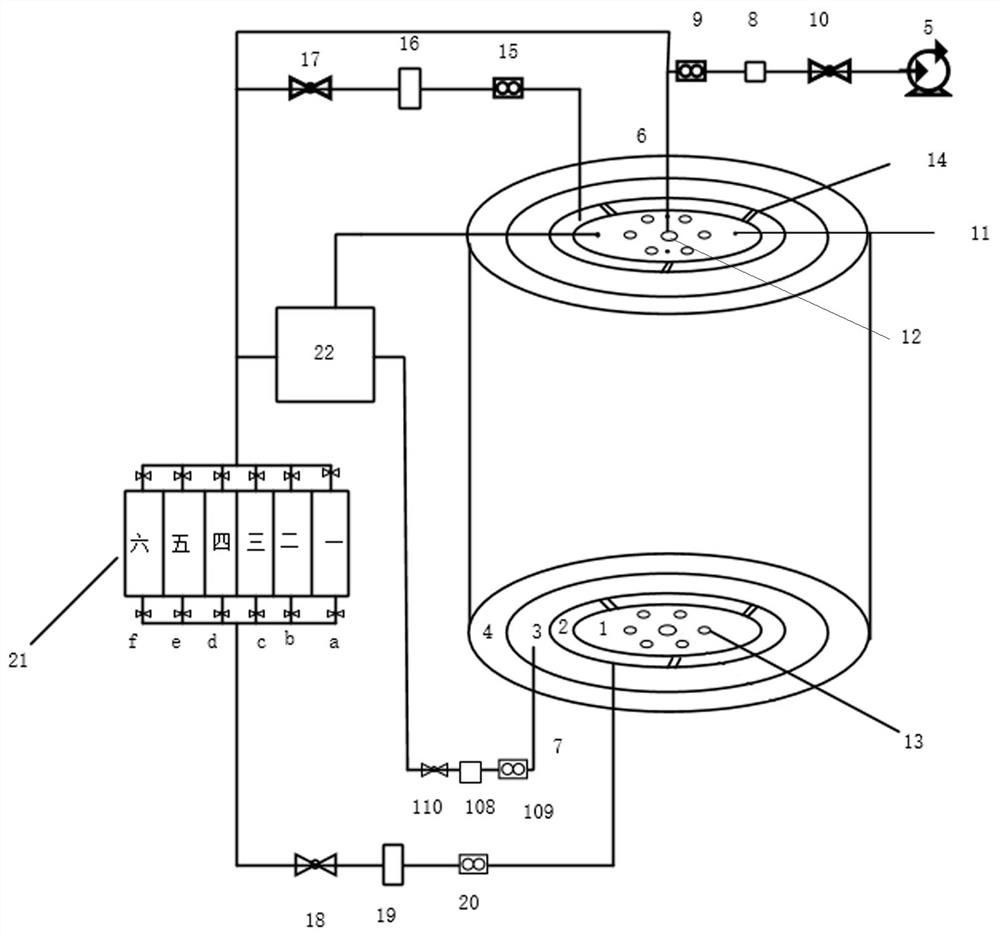

[0046] Such as Figure 1 to Figure 5 As shown, a magnesium hydride solid-state hydrogen energy storage system of the present invention includes a hydrogen storage and discharge tank and an external cold and hot fluid storage tank.

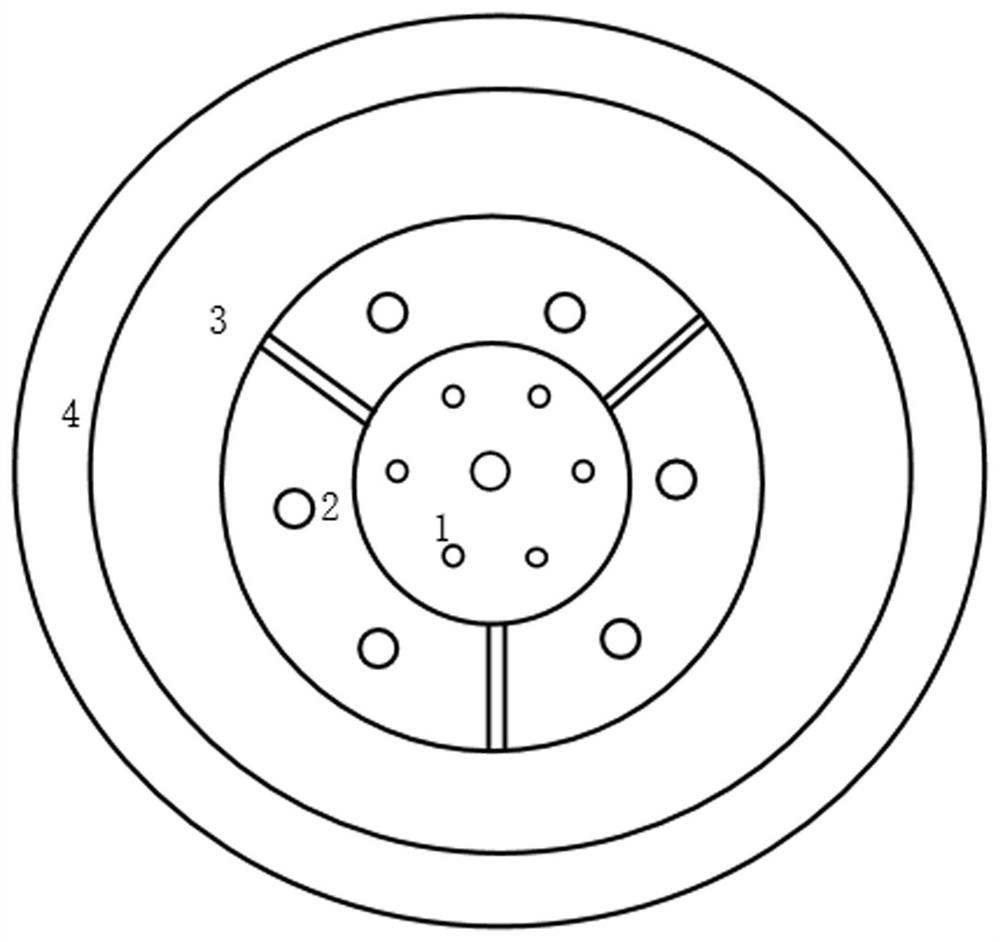

[0047] The hydrogen storage and discharge tank is radially outward from the center and is sequentially composed of a magnesium hydride porous medium hydrogen storage layer 1, a liquid cooling layer 2, a vacuum layer 3 and an insulation layer 4, wherein:

[0048] The magnesium hydride porous medium hydrogen storage layer 1 is provided with an air guide pipe 6 shared by the import and export of hydrogen, a heat conduction pipe 13 and an internal temperature measurement point 11, the air guide pipe 6 is connected with a hydrogen storage and discharge pipeline, and a pump 5, Valve 10, flow meter 9 and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com