Method for preparing polyether polyol with low viscosity, low unsaturation degree, low odor and high activity

A high-activity polyether and polyol technology is applied in the field of preparing low-viscosity, low-unsaturation, low-odor, high-activity polyether polyols, and can solve the problems of poor physical properties and odor, complicated refining process, and long reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

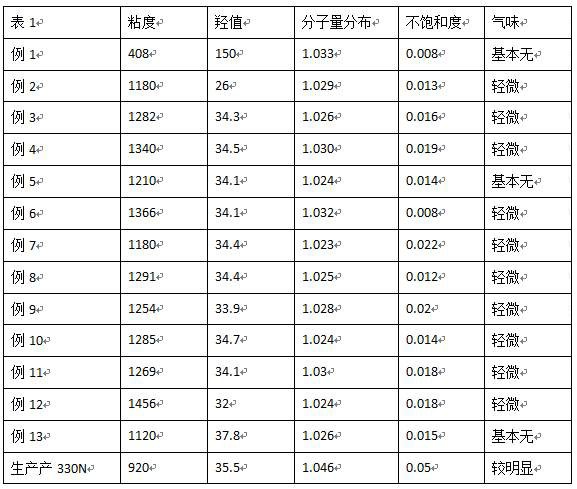

Examples

Embodiment 1

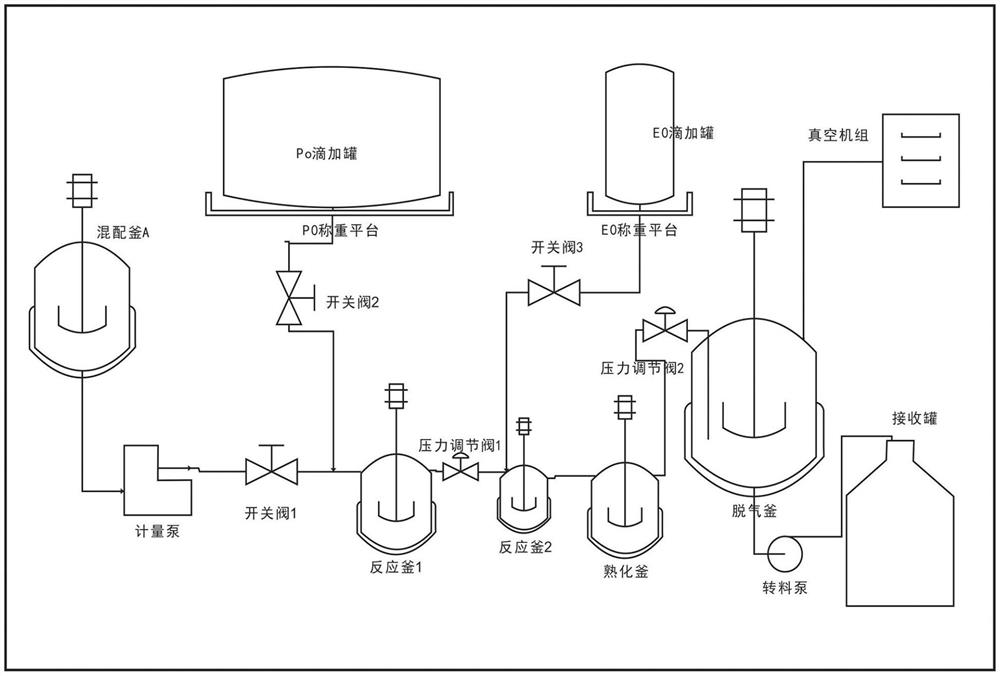

[0021] (1) First replace the entire device with nitrogen, and check that the airtightness is qualified (the whole device includes a 2L mixing tank, a 10L PO dropping tank, a 2L EO dropping tank, a 1L reactor 1, and a 0.5L reactor 2, 1L aging kettle, 3L degassing kettle, 3L receiving tank);

[0022] (2) Add initiator 300g glycerin and 1200g basic polyether 305 (3-500 molecular weight, self-produced by the factory) into the mixing tank, heat up to 100°C after dehydration is qualified, carry out nitrogen replacement, and then add 12.6 under nitrogen protection g phosphazene catalyst, stirred and mixed;

[0023] (3) Click on the feeding program controlled by the computer, feed 250g of polymerized substrate into Reactor 1 from the mixing tank, start stirring to raise the temperature to 100 degrees, and start PO dropwise addition. After the reaction is activated, feed about 750g of PO. At this time, the liquid level of Reactor 1 Basically full, start the normal feeding program at t...

Embodiment 2

[0025] (1) First replace the entire device with nitrogen, and check that the airtightness is qualified (the whole device includes a 2L mixing tank, a 10L PO dropping tank, a 2L EO dropping tank, a 1L reactor 1, and a 0.5L reactor 2, 1L aging kettle, 3L degassing kettle, 3L receiving tank);

[0026] (2) Add 1250g of initiator 1250g of basic polyether 204 (2 official 400 molecular weight, self-produced by the factory) 1136g into the mixing tank, heat up to 100°C and dehydrate, then carry out nitrogen replacement, and then add 25g of phosphazene under nitrogen protection Catalyst, stir and mix;

[0027] (3) Click on the computer-controlled feeding program, and the mixing tank feeds 113.6g of the polymer substrate into Reactor 1, starts stirring and raises the temperature to 100 degrees, and then starts PO dropwise addition. After the reaction is activated, PO feeds about 886.4g. At this time, Reactor 1 The liquid level is almost full. At this time, the normal feeding program is ...

Embodiment 3

[0029] (1) First replace the entire device with nitrogen, and check that the airtightness is qualified (the whole device includes a 2L mixing tank, a 10L PO dropping tank, a 2L EO dropping tank, a 1L reactor 1, and a 0.5L reactor 2, 1L aging kettle, 3L degassing kettle, 3L receiving tank);

[0030] (2) Add starter agent 1172g basic polyether 305 (3-500 molecular weight, self-produced by the factory) to the mixing tank, heat up to 100°C and dehydrate to pass the nitrogen replacement, then add 23g of phosphazene catalyst under the protection of nitrogen , stir well;

[0031](3) Click on the computer-controlled feeding program, and the mixing tank feeds 117.2 g of the polymer substrate into Reactor 1, and then starts stirring to raise the temperature to 100 degrees, and then starts PO dropwise addition. After the reaction is activated, PO feeds about 882.8 g. At this time, Reactor 1 The liquid level is almost full. At this time, the normal feeding procedure is started. The mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com