Slurry reactor hydrocracking reaction system and method

A technology of hydrocracking and reaction system, applied in hydrocarbon oil cracking, petroleum industry and other directions, to avoid bottom coking, low equipment cost, and overcome technical difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

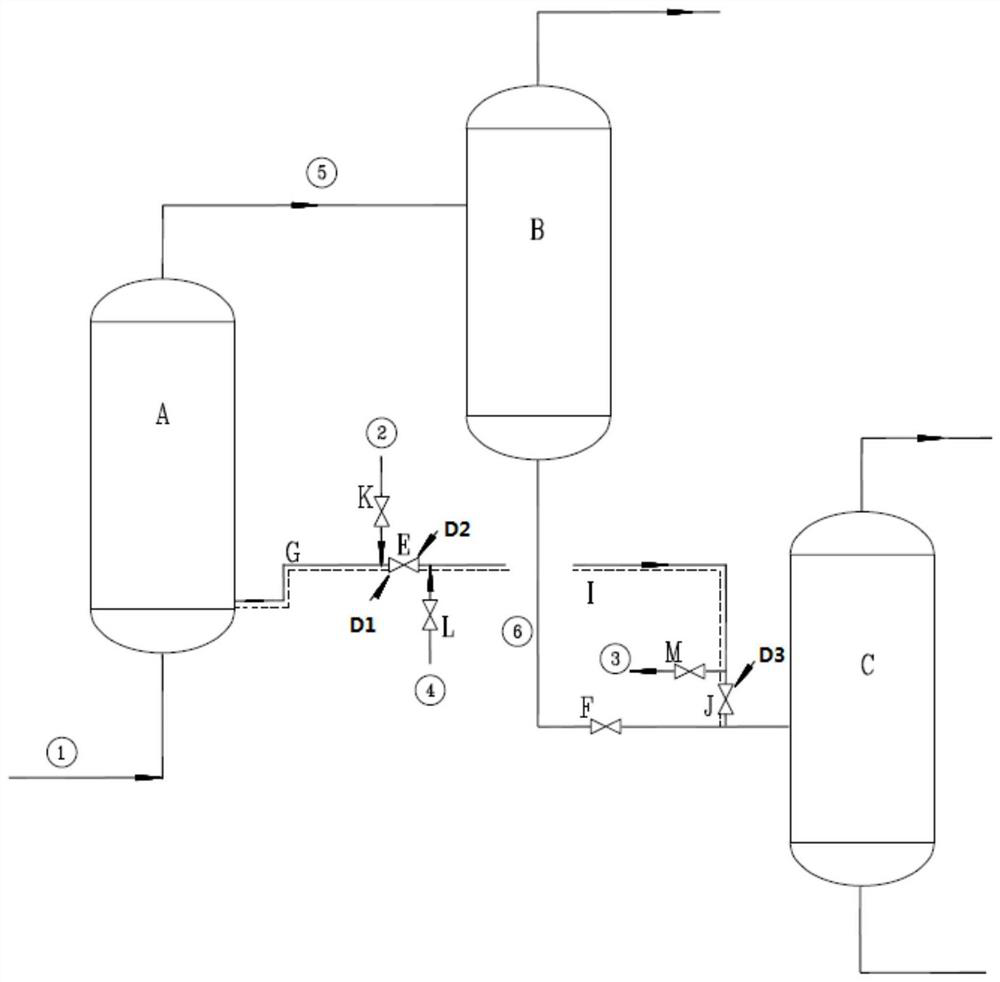

[0032] A slurry bed hydrocracking reaction system, comprising: a slurry bed hydrocracking reactor A, a reaction product separator B, a discharge pipeline G, a flushing system, a purging system, and a discharge separator C; wherein,

[0033] The top of the slurry bed hydrocracking reactor A is connected to the reaction product separator B, and the lower part is connected to the discharge separator C through the discharge pipeline G; the bottom of the reaction product separator B is connected to the discharge separator C through a pipeline, and an isolation valve F;

[0034] The discharge pipeline G is provided with a pressure reducing valve E and an isolating valve group J in sequence; the discharge pipeline G is provided with a heating pipeline I, and the flushing interface D2 and the purge interface D1 are arranged on the pressure reducing valve E.

[0035] The purge system communicates with the discharge pipeline G through the purge interface D1, and the flushing system comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com