A turbine-type combined anti-friction tool capable of changing the flow state of drilling fluid

A flow state and drilling fluid technology, which is applied in the directions of liquid/gas jet drilling, earthwork drilling, flushing of boreholes, etc., can solve the problems of low rock-carrying capacity of drilling fluid, unsatisfactory vibration effect, and low drilling efficiency, etc., to achieve The effect of small pressure drop, reduced friction and improved life of drilling tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to understand the technical features, objects and effects of the present invention, specific embodiments of the present invention will be described with reference to the drawings.

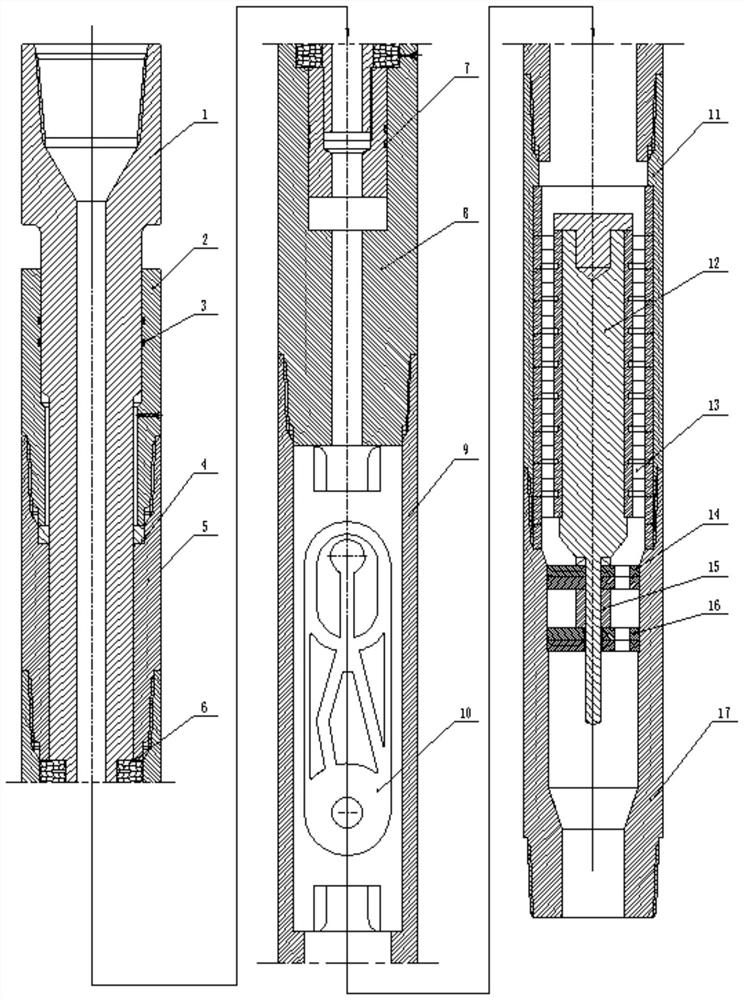

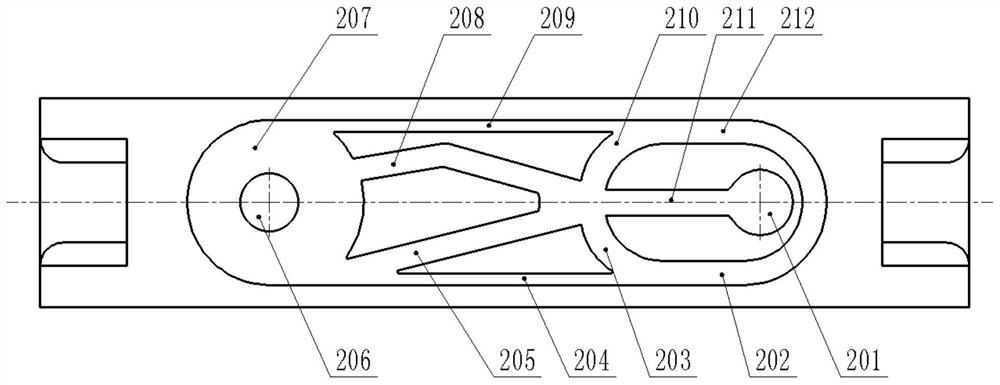

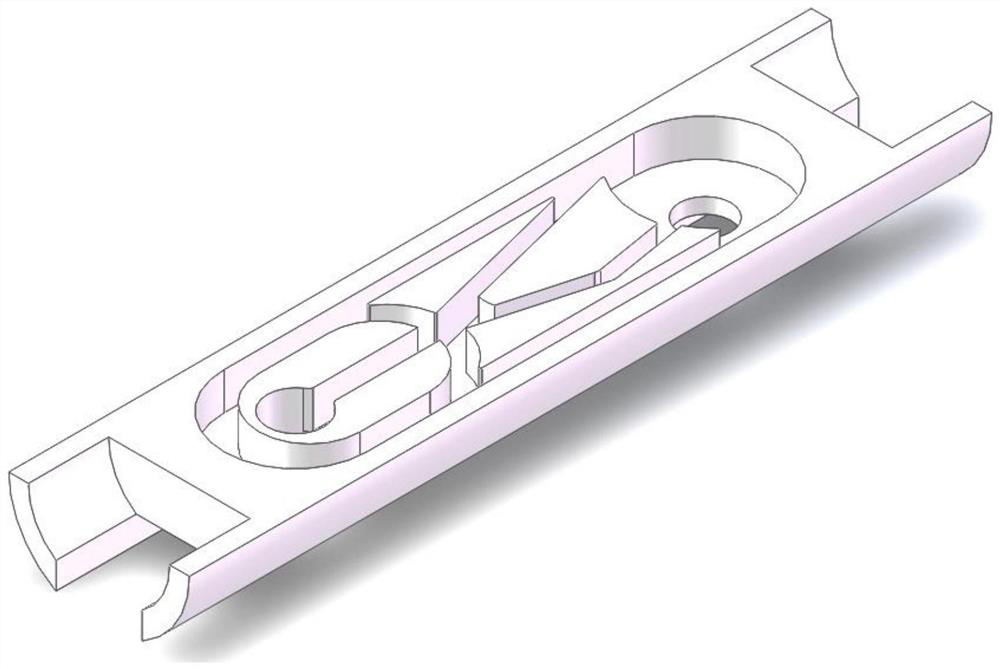

[0015] like Figure 1 - Figure 5 As shown, the turbine combination of the drilling fluid flow state is mainly mainly rod 1, the upper casing A2, the O-shaped seal A3, the limit ring 4, the upper casing B5, the disc spring 6, O-shaped seal B7, housing A8, housing B9, pulse generator 10, lower casing 11, mandrel 12, turbine 13, valve A14, sleeve 15, valve B16, the lower joint 17, the technology is characterized in that the lever 1 Connect to the upper housing B5 by the spline; upper housing A2, the upper casing B5, the outer casing A8, the outer casing B, the lower casing 11, and the lower joint 17 are sequentially connected by the threads; the fluid inlet cone is located in the draw rod 1 inlet At equivalent to a tube, it is used to increase the fluid pressure difference, the improvement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com