Highly accelerated aging test device and method for polymer materials

A technology of polymer materials and aging test, applied in the field of high-accelerated aging test devices of polymer materials, can solve the problems of long test period and low reflectivity, and achieve the effect of high durability, high ultraviolet reflectivity and expanding the number of installations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

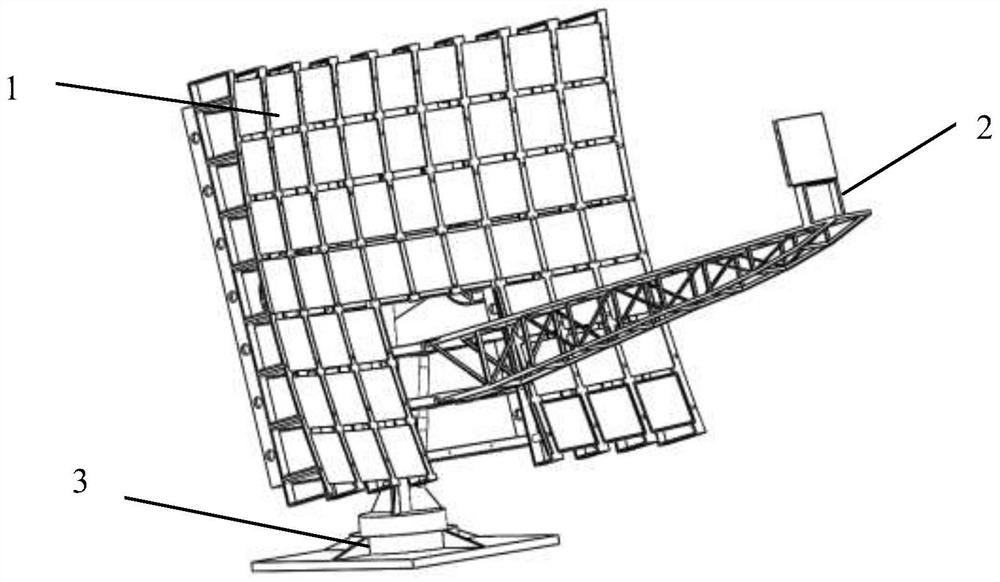

[0078] The high-accelerated aging test device for polymer materials provided in this embodiment includes:

[0079] UV light reflection system 1;

[0080] Sample temperature control system 2;

[0081] Sun Tracking System 3;

[0082] Multi-environmental factors coordinated control system;

[0083] in:

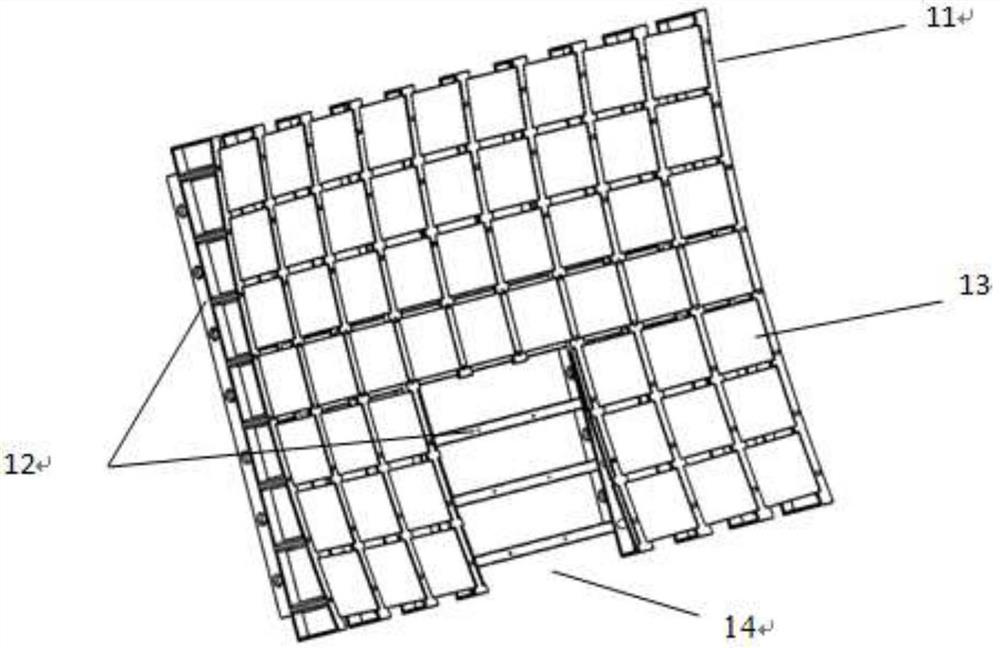

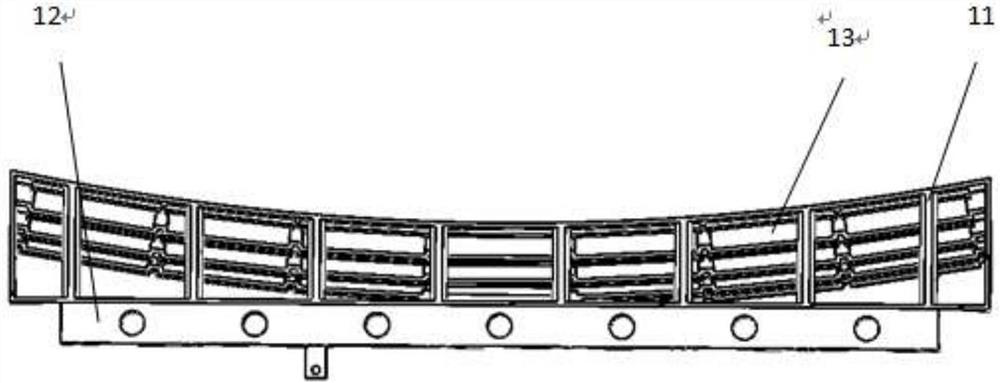

[0084] Such as Figure 1-4 As shown, the main structure of the ultraviolet light reflection system 1 is spherical concave, mainly composed of a concave frame 11 and a fixing frame 12 for fixing the concave frame, and a plurality of reflectors 13 are arranged on the concave frame.

[0085] Such as Figure 5-7 As shown, the sample temperature control system 2 includes a support 21 , a sample stage 22 and a temperature control mechanism 23 . One end of the support 21 is connected to the ultraviolet light reflection system 1, and the other end is provided with a sample stage 22. The sample stage 22 is provided with a sample and a temperature control mechanism 23 for controlling...

Embodiment 2

[0143] Different from Example 1,

[0144] The material of the combined reflective film of the reflective mirror 13 is different.

[0145] Incidence at 8 degrees, HfO 2 / ZrO 2 / SiO 2 Combined high ultraviolet reflective film (band 240 ~ 400nm, average reflectance> 96.3%) as an example, further illustrate the importance of the number of film layers to reflective film ultraviolet reflectance, high reflective bandwidth and durability improvement during structure control, this method Include the following steps:

[0146] (1) Design of reflective film: construct HfO based on optical thin film design software (such as Essential Macleod, Optilayer, TFCalc) 2 / ZrO 2 / SiO 2 Combined UV reflective film, the reflective film structure is divided into three layers, which are the bottom film layer for ultraviolet reflection, the middle film layer and the top film layer for improving durability.

[0147]Specifically, the bottom layer structure is (aHbL) 10 (cHbL) 10 (dHbL) 10 , H is...

Embodiment 3

[0161] Refer to Example 1 for the high-accelerated aging test device for polymer materials provided in this example.

[0162] A method for performing a high-density polyethylene high-accelerated aging test using a high-molecular material high-accelerated aging test device, comprising the following steps:

[0163] 1) Turn on the power, switch the sun tracking system to manual mode through the control box, and lower the equipment sample stage through the vertical rotation device.

[0164] 2) High-density polyethylene is processed into a plate by compression molding, and the melting point is 142°C through a dumbbell knife; the samples are fixed on the sample stage in sequence through the clamping position, and the back of the sample is attached to the sample stage, so that the temperature of the sample can be fully cooled .

[0165] 3) After the sample is fixed, turn on the fan and cooling cycle, and set the temperature upper limit protection at the same time. The upper limit of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com