Transmission electron microscope sample wire carrier, and production method and application thereof

A technology of transmission electron microscope samples and sample wires, applied in the direction of material analysis, instruments, and measuring devices using wave/particle radiation, to achieve stable performance, reduce damage, and reduce changes in contact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

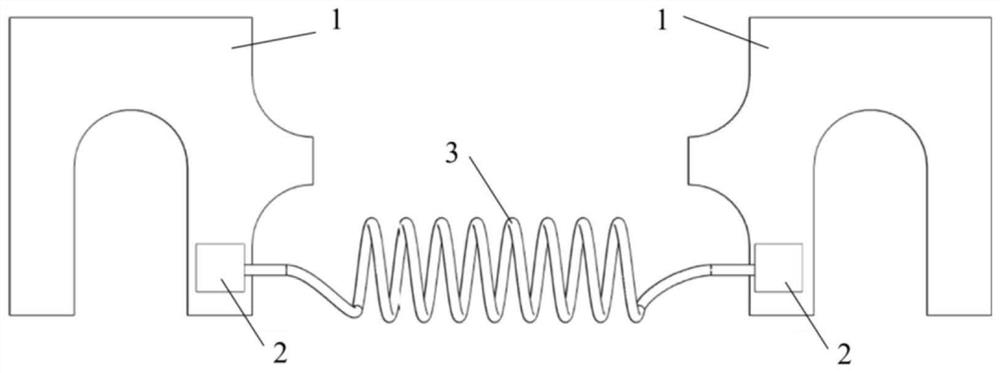

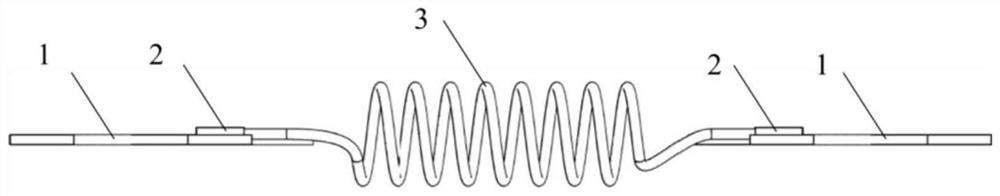

[0065] This embodiment provides a method for preparing a transmission electron microscope sample wire carrier, comprising the following steps:

[0066] 1) A spiral sample wire with a diameter of 0.2 mm is selected, wherein the material of the spiral sample wire is tungsten, the number of turns is 13, and the length is 6 mm;

[0067] 2) Place the two ends of the spiral sample wire on a semi-concave gasket cleaned with water and ethanol, wherein the semi-concave gasket is made of copper and has a thickness of 0.3mm;

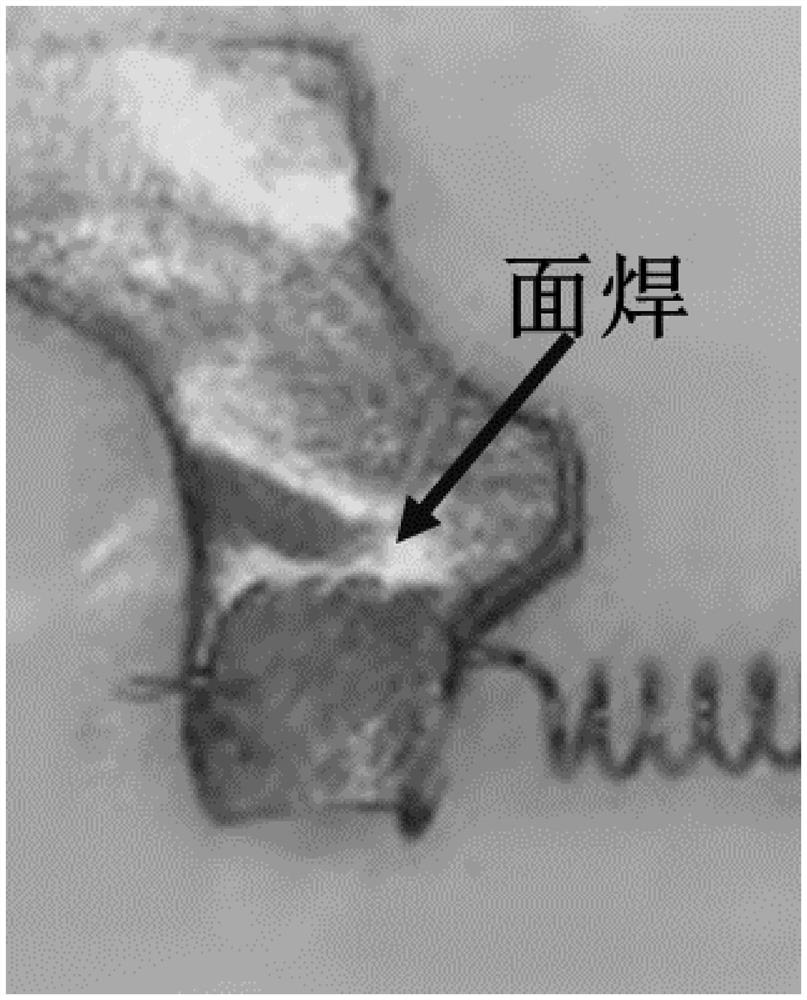

[0068] 3) Then cover the two ends of the spiral sample wire with the welding pieces cleaned with water and ethanol respectively. The material of the welding pieces is copper, the size is 2mm×2mm square, and the thickness is 0.2mm; Sheet welding, wherein the welding temperature is 1200°C, and the welding time is 3s, so as to achieve the purpose of bonding and fixing the soldering sheet on the pad, and clamping and fixing the two ends of the spiral sample wire, and o...

Embodiment 2

[0078] The present invention provides an in-situ observation experiment of the TEM sample wire carrier prepared in Example 1, comprising the following steps:

[0079] Use the hydrothermal method to prepare ZIF-67 crystal, and disperse the product powder in ethanol to obtain dispersion liquid; After the surface of the sample wire is dried, move the transmission electron microscope sample wire stage to the transmission electron microscope. During the observation, a current was applied to the TEM sample wire stage, and the corresponding measured temperature was 200°C, and recorded and photographed at this temperature as follows: Figure 6 ~ Figure 8 shown.

[0080] The result is as Figure 6 ~ Figure 8 As shown, the results show that when the TEM sample wire stage prepared in Example 1 is used for in-situ observation of the TEM, it is found that it has a good effect on the real-time heating of the sample (200 ° C) and the application of in-situ observation.

Embodiment 3

[0082] This embodiment provides a method for preparing a transmission electron microscope sample wire carrier, comprising the following steps:

[0083] 1) A spiral sample wire with a diameter of 0.3 mm is selected, wherein the material of the spiral sample wire is tungsten, the number of turns is 12, and the length is 7 mm;

[0084] 2) Place the two ends of the spiral sample wire on a semi-concave gasket cleaned with water and ethanol, wherein the semi-concave gasket is made of titanium and has a thickness of 0.3 mm;

[0085] 3) Then cover the two ends of the spiral sample wire with the welding pieces cleaned with water and ethanol respectively, wherein the material of the welding pieces is aluminum, the specification is a circle with a diameter of 3mm, and a thickness of 0.1mm; Welding and melting of the soldering sheet, wherein the welding temperature is 700°C, and the welding time is 2s, so as to achieve the purpose of bonding and fixing the soldering sheet on the gasket, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com