3D printing cerebral hemorrhage model for puncture training and efficient manufacturing method thereof

A 3D printing and model technology, applied in the field of medical teaching, can solve the problems of time-consuming, easy to change, difficult to operate, etc., and achieve the effect of ensuring absolute accuracy, preventing material waste, and accurate skull position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0094] Embodiment two: if Figure 11 As shown, on the basis of Embodiment 1, the simulated hematoma 5 is directly positioned at the position of the foramen magnum through the positioning rod 52, and the inside of the hematoma cyst wall 511 can be perfused and filled with the first transparent flexible material directly from the position of the foramen magnum to form a simulated The blood clot 512 does not need to be additionally provided with a skull base base 4, and has a simple structure and is easy to operate.

[0095] When filling the simulated brain tissue 6 , the external auxiliary structure can be used to assist the limit positioning rod 52 and the simulated blood mass 5 .

Embodiment 3

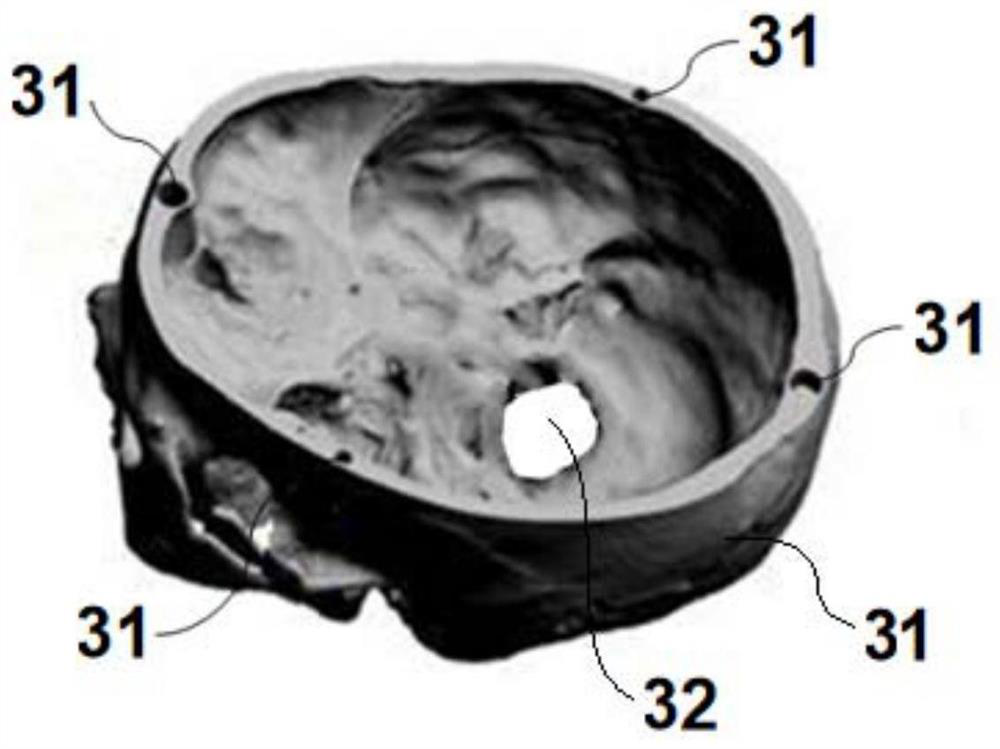

[0096] Embodiment 3: On the basis of Embodiment 1, a plurality of positioning rods are arranged inside the lower skull 3, and a plurality of trays 53 are fixedly supported by the plurality of positioning rods, and a simulated hematoma 51 can be fixedly arranged above each tray 53, To simulate multiple cerebral hematomas; in this embodiment, a maximum of 12 trays can be fixedly set, which can simulate the simultaneous occurrence of 12 hematomas.

[0097] The actual operation process of the present invention is as follows:

[0098] 1. Collect medical digital imaging and communication DICOM (hereinafter referred to as DICOM) data of brain CT of patients with cerebral hemorrhage clinically, import it into a computer with Mimics software installed, open the DICOM data, perform 3D reconstruction, and perform corresponding processing according to the model requirements:

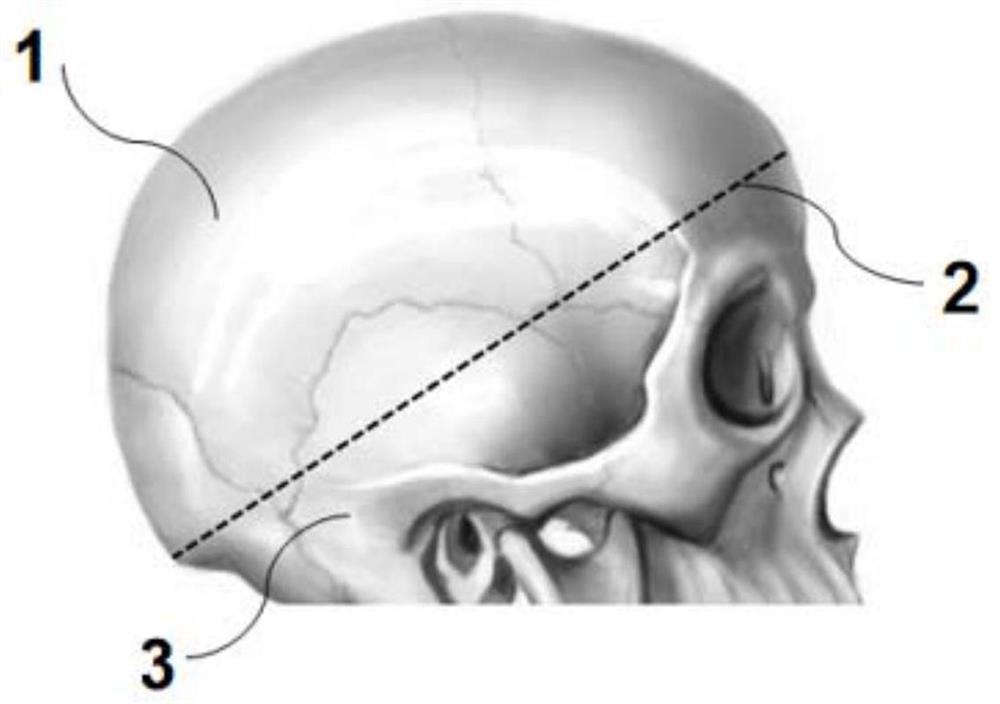

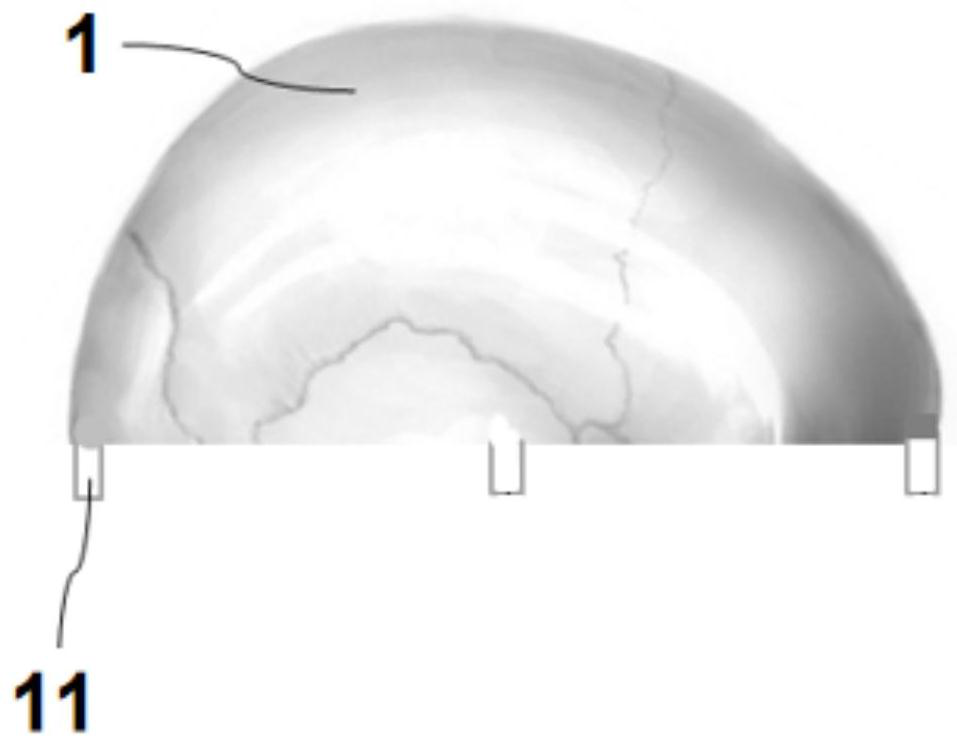

[0099] 1) Skull reconstruction and design processing: After reconstructing the skull with Mimics software, design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com