High-temperature-resistant and high-strength diaphragm and preparation method thereof

A high-strength, high-temperature-resistant technology, applied to structural parts, electrical components, battery pack components, etc., can solve problems such as short circuit, puncture, and potential safety hazards, and achieve the effect of improving safety performance and avoiding short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

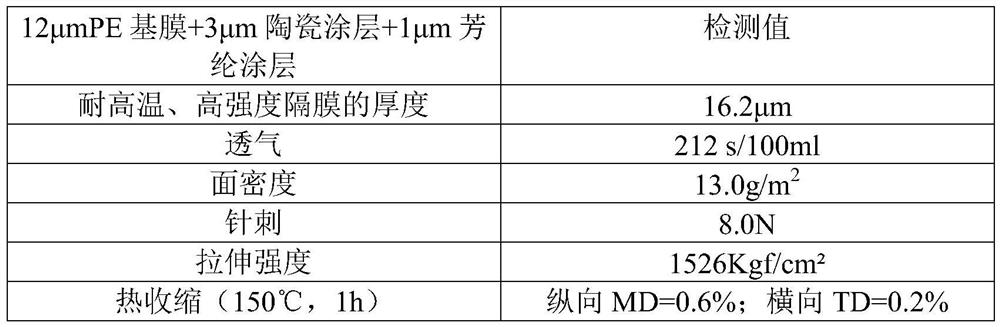

Embodiment 1

[0030] A method for preparing a high-temperature-resistant, high-strength diaphragm, comprising the following steps:

[0031] 1) Coat the water-based ceramic slurry on the base film by micro-gravure roller coating, the base film is PE, so that a ceramic coating with a thickness of 3 μm is formed on the base film, and dry at 60°C for 3 minutes to obtain a ceramic coating diaphragm;

[0032] 2) Coating aramid slurry on the ceramic coating by micro-gravure roller coating to form an aramid coating with a thickness of 1 μm on the ceramic coating, and extracting to obtain a high-temperature-resistant, high-strength diaphragm; , the extractant used in the extraction is water,

[0033] The method for preparing the water-based ceramic slurry is: add 7.5 parts by mass of boehmite powder and 0.085 parts by mass of dispersant to 12 parts by mass of deionized water, stir at a speed of 1000rpm for 0.5h until uniform, and then add 0.05 Thickener in parts by mass, defoamer in 0.12 parts by ...

Embodiment 2

[0038] A method for preparing a high-temperature-resistant, high-strength diaphragm, comprising the following steps:

[0039] 1) Coat the water-based ceramic slurry on the base film by micro-gravure roller coating, the base film is PE, so that a ceramic coating with a thickness of 3 μm is formed on the base film, and dry at 80°C for 4 minutes to obtain a ceramic coating diaphragm;

[0040] 2) Coating aramid slurry on the ceramic coating by micro-gravure roller coating to form an aramid coating with a thickness of 1 μm on the ceramic coating, and extracting to obtain a high-temperature-resistant, high-strength diaphragm; , the extractant used in the extraction is a mixed solution, the mixed solution is a mixture of water and DMAC, and the concentration of DMAC in the mixed solution is 25wt%,

[0041] The method for preparing the water-based ceramic slurry is as follows: add 7.5 parts by mass of alumina powder and 0.1 parts by mass of dispersant to 12 parts by mass of deionized...

Embodiment 3

[0046] A method for preparing a high-temperature-resistant, high-strength diaphragm, comprising the following steps:

[0047] 1) Coat the water-based ceramic slurry on the base film by means of micro-gravure roll coating, the base film is PE, so that a ceramic coating with a thickness of 3 μm is formed on the base film, and dry at 75°C for 2 minutes to obtain a ceramic coating diaphragm;

[0048] 2) Coating aramid slurry on the ceramic coating by micro-gravure roller coating to form an aramid coating with a thickness of 1 μm on the ceramic coating, and extracting to obtain a high-temperature-resistant, high-strength diaphragm; , the extractant used in the extraction is a mixed solution, the mixed solution is a mixture of water and DMAC, and the concentration of DMAC in the mixed solution is 40wt%,

[0049] The method for preparing the water-based ceramic slurry is as follows: add 6 parts by mass of alumina powder and 0.11 parts by mass of dispersant to 12 parts by mass of dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com