Ceramic article production method and ceramic article

A technology for ceramic products and manufacturing methods, which is applied in the direction of ceramic products, ceramic layered products, manufacturing tools, etc., and can solve the problems of crack formation, inability to obtain high-strength porous structures, and difficulty in obtaining ceramic molding products with modeling precision porous structures, etc. achieve high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0119] In this example, a porous portion was fabricated with a grid-like pattern. The porous portion roughly corresponds to the case where the hole pitch of the grid-like pattern is 175 μm.

[0120]

[0121] prepared α-Al 2 o 3 Powder, Gd 2 o 3 Powder and Tb 2 o 3.5 Powder (Tb 4 o 7 powder), the powder is weighed so that its molar ratio is Al 2 o 3 :Gd 2 o 3 :Tb 2 o 3.5 =77.4:20.8:1.8. The weighed powders were mixed with a dry ball mill for 30 minutes to obtain mixed powders (material powders).

[0122] When the composition of the above-mentioned material powder is analyzed by ICP emission spectrometry, the content of zirconia is less than 0.1 mol%.

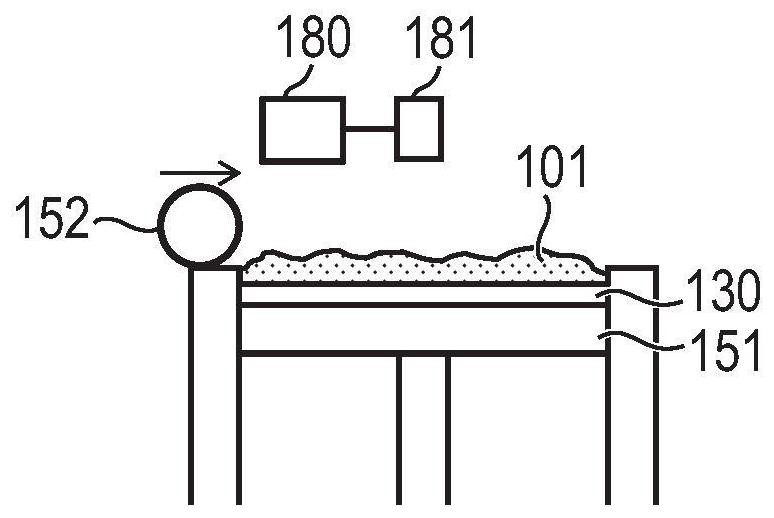

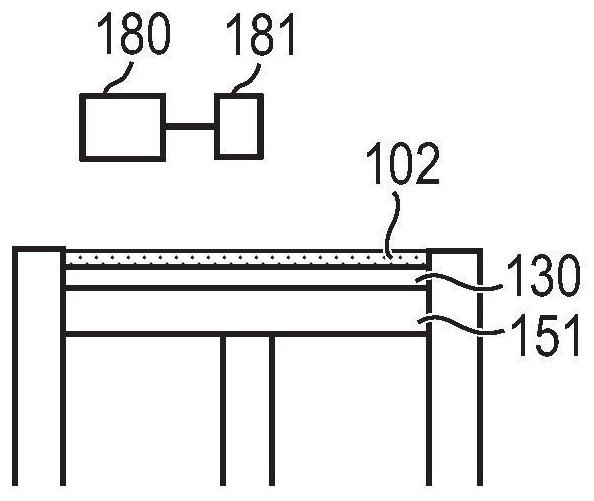

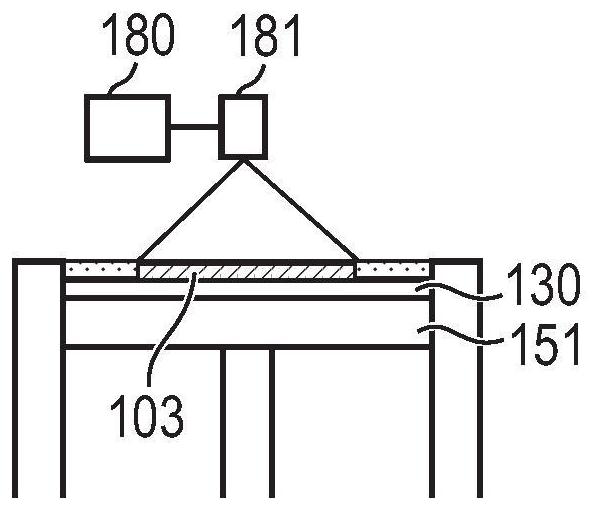

[0123] Next, pass the above Figure 1A to Figure 1H The steps shown are essentially the same steps to form the shaped article of Example 1.

[0124] For forming the molded article, ProX DMP 100 (product name) manufactured by 3D SYSTEMS on which a 50W Nd:YAG laser (beam diameter: 65 μm) was mounted was used.

...

example 2

[0142] This example is an example in which the content of the zirconium component in the porous portion is different.

[0143] Porous ceramics were produced under the same conditions as in Example 1 except that the immersion step (step (iii)) and the heating step (step (iv)) in the zirconium-containing component liquid were each alternately repeated twice. The produced porous ceramic product was evaluated in the same manner as in Example 1.

example 3

[0145] This example is one in which the arrangement of the openings in the porous portion is random.

[0146] A porous ceramic product was produced under the same conditions as in Example 1 except that the stretching speed was set at 220 mm / s, and the stretching pitch was set at 125 μm, to obtain a porous portion with randomly arranged open cells. The optical microscopic image of the porous part as Figure 4B shown. The produced porous ceramic product was evaluated in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com