A method for improving aggregate removal by protein a chromatography

A chromatography and protein technology, applied in the field of protein A chromatography to remove antibody aggregates, to reduce the burden, improve the removal ability, and improve the overall robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

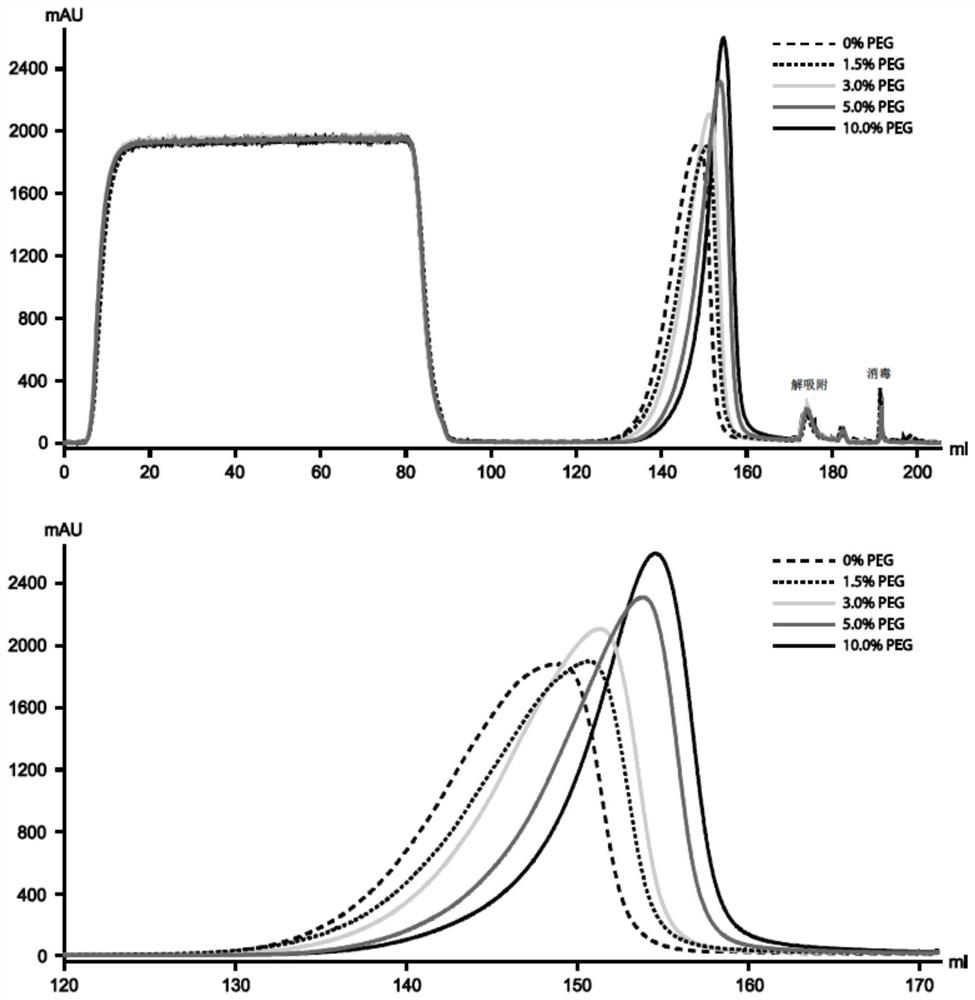

[0073] Example 1: Effect of PEG on protein A elution curve

[0074] In this study, we first investigated the effect of PEG on the eluting curve of the protein A by adding different amounts of PEG (ie 1.5%, 3%, 5% and 10%) to the cleaning and elution buffer. With the increase in PEG concentration, the retention rate of easy-to-gathered antibodies is slightly improved, and eluting peaks become sharp ( figure 1 ). However, different from other types of columns (eg, ion exchange, hydrophobic interaction, and mixing mode), PEG (up to 10%) has no effect on the monomer-aggregate separation of the protein A column. This observation explained the previous lack of reports on the application of PEG to aggregates in protein A.

Embodiment 2

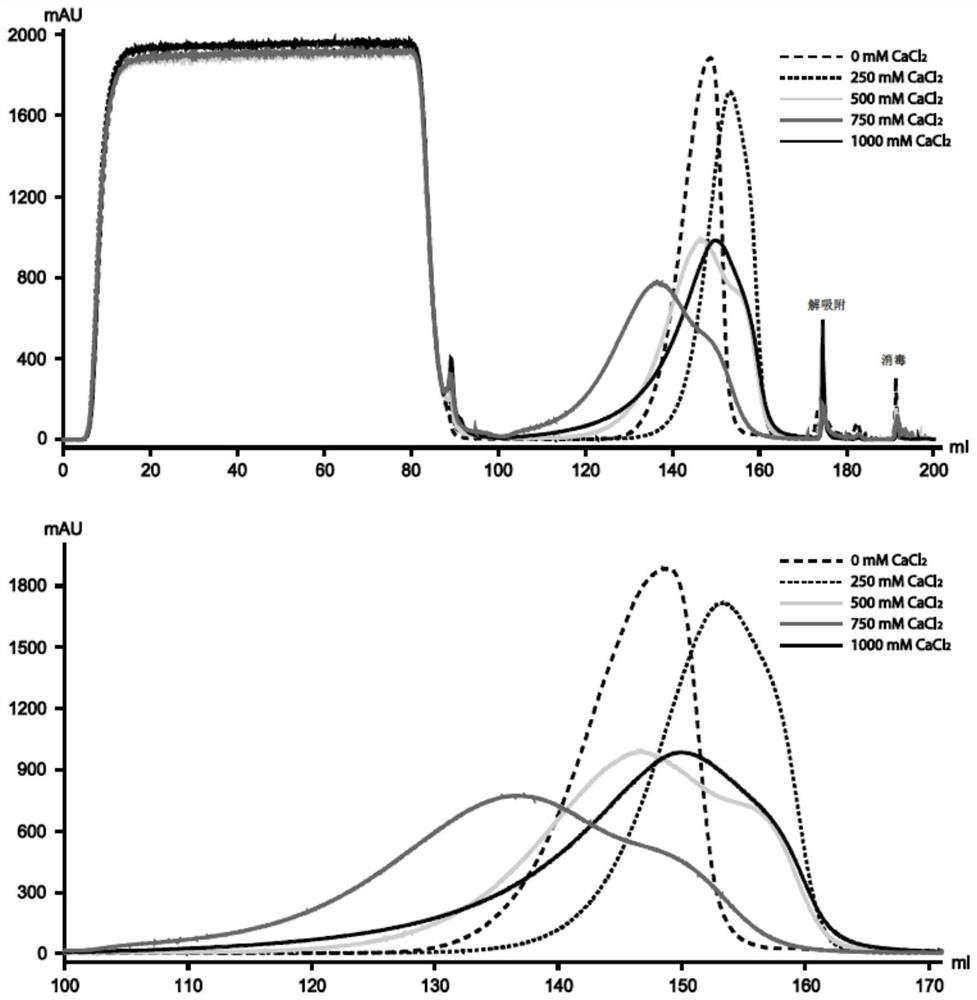

[0075] Example 2: Effect of Calcium chloride on the eluting curve of protein A

[0076] The present invention designs experiments to explore calcium chloride as a liquid phase additive to the separation of monomer - aggregate. For the case studied, different amounts of calcium chloride (ie 250 mm, 500 mM, 750 mM, and 1M) were added to the protein A cleaning and elution buffer.

[0077] Adding Calcium chloride to the flow phase showed awareness but not significant effect on the separation and retention time ( figure 2 ). At low concentration (ie 250 mM), calcium chloride has little effect on separation, and eluting peaks are similar to the elution peaks that do not contain the salt (in both cases, eluting peaks are relatively sharp) ). However, calcium chloride in this concentration increases the retention time of the target protein. At an increased concentration (i.e., 500 mM and 750 mM), calcium chloride showed a small amount of impact on the separation. Under these two condition...

Embodiment 3

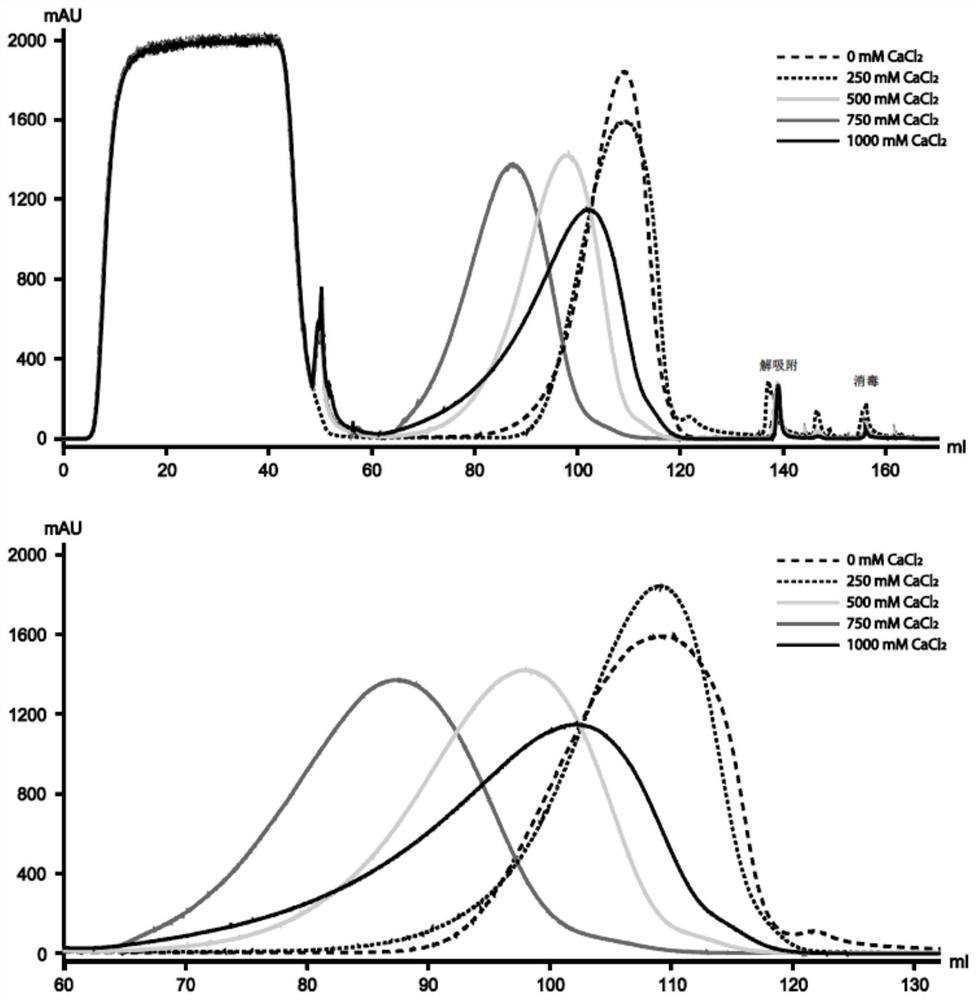

[0079] Example 3: Synergistic effect of PEG and calcium chloride on protein A separation

[0080] Although calcium chloride increases the monomer-aggregate separation at 500 mm and 750 mm, the separation of two substances under these conditions is still not complete enough. Therefore, the inventors will then attempt to combine PEG / chloride. Since PEG itself has little effect on elution curve at different concentrations, the inventors in this study have arbitrarily selected 5% PEG and different amounts of calcium chloride. In the calcium chloride concentration (i.e., 150 mm and 250 mm), this combination did not show significant effects, and the elution curve was almost consistent with only 5% PEG. Figure 4 A). However, the combination of 500 mM Calcium chloride and 5% PEG exhibits a stringent synergistic effect, resulting in a significant increase in the separation of monomers and aggregates ( Figure 4 B). The monomers in the eluent were raised from 80% (cleaning 2 and the elutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com