Freeze-dried powder preparation with multiple effects of moisturizing, whitening, relieving and repairing and preparation method of freeze-dried powder preparation

A freeze-dried powder and preparation technology, which is applied to skin care preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problem of inability to achieve skin conditioning, inability to comprehensively satisfy consumers, and poor whitening and soothing effects. and other problems, to achieve the effect of less water content, stable properties, and stable structure of peptide substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

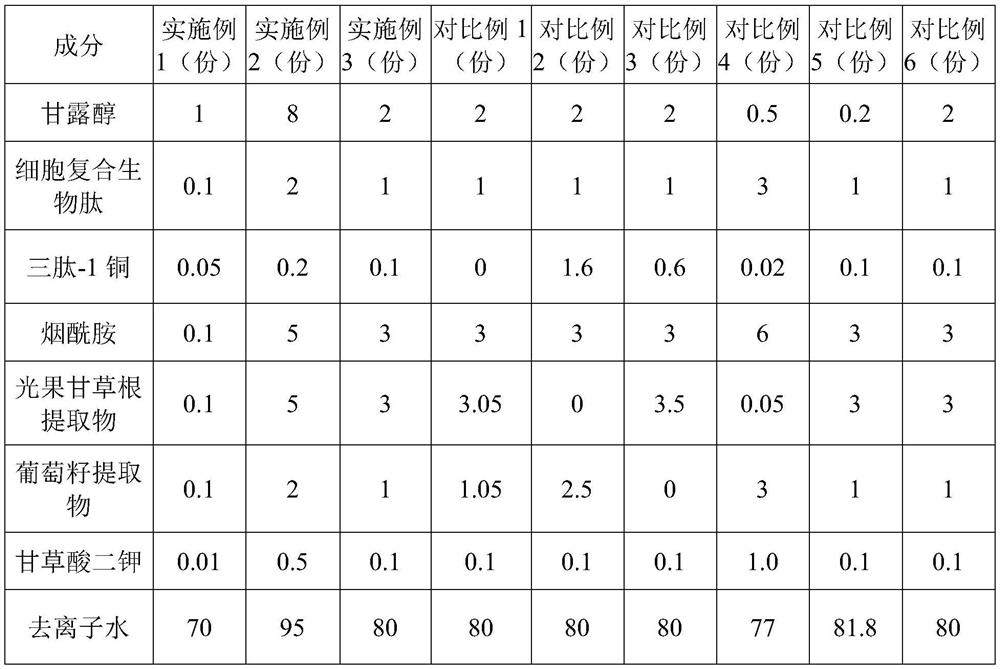

[0043] The raw materials of this embodiment are as shown in Table 1, and its preparation process is as follows:

[0044] (1) Use deionized water to stir and dissolve the above-mentioned various ingredients evenly, filter and sterilize, divide into vials, and place them in a vacuum freeze dryer with a half stopper;

[0045] (2) Lower the temperature to -40°C and keep it for 12 minutes;

[0046] (3) Heat up to -37°C within 160min, and keep at -37°C for 160min;

[0047] (4) Warm up to -18°C within 350min, start sublimation dehydration, keep warm at -18°C for 950min, replenish purified air while vacuuming, keep vacuum at 12Pa, sublimation dehydration;

[0048] (5) Increase the temperature to 28°C within 350 minutes, replenish the purified air while vacuuming, keep the vacuum at 13Pa, and continue sublimation and dehydration;

[0049] (6) Insulate at 28°C for 380 minutes, replenish purified air while vacuuming, keep the vacuum at 13Pa, and continue sublimation and dehydration;

...

Embodiment 2

[0053] The raw materials of this embodiment are as shown in Table 1, and its preparation process is as follows:

[0054] (1) Use deionized water to stir and dissolve the above-mentioned various ingredients evenly, filter and sterilize, divide into vials, and place them in a vacuum freeze dryer with a half stopper;

[0055] (2) Lower the temperature to -50°C and keep it for 8 minutes;

[0056] (3) Warm up to -32°C within 200min, and keep at -32°C for 140min;

[0057] (4) Raise the temperature to -12°C within 370 minutes, start sublimation dehydration, keep warm at -12°C for 850 minutes, replenish and purify air while vacuuming, keep the vacuum at 12Pa, and start sublimation dehydration;

[0058] (5) Warm up to 35°C within 370 minutes, replenish and purify air while vacuuming, keep the vacuum at 12Pa, and continue sublimation and dehydration;

[0059] (6) Insulate at 35°C for 340 minutes, replenish purified air while vacuuming, keep the vacuum at 12Pa, and continue sublimation...

Embodiment 3

[0063] The raw materials of this embodiment are as shown in Table 1, and its preparation process is as follows:

[0064] (1) Use deionized water to stir and dissolve the above-mentioned various ingredients evenly, filter and sterilize, divide into vials, and place them in a vacuum freeze dryer with a half stopper;

[0065] (2) Lower the temperature to -44°C and keep it for 10 minutes;

[0066] (3) Heat up to -35°C within 180min, and keep at -35°C for 150min;

[0067] (4) Raise the temperature to -15°C within 360min, start sublimation dehydration, keep warm at -15°C for 900min, supplement the purified air while vacuuming, keep the vacuum degree at 12Pa, sublimation dehydration;

[0068] (5) Increase the temperature to 30°C within 360 minutes, supplement the purified air while vacuuming, keep the vacuum at 12Pa, and continue sublimation and dehydration;

[0069] (6) Insulate at 30°C for 360 minutes, replenish purified air while vacuuming, keep the vacuum at 13Pa, and continue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com