Lifting equipment with high safety coefficient for high-precision machining

A safety factor, machining technology, applied in the direction of metal processing equipment, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of rapid falling of lifting equipment, endanger the personal safety of staff, hidden dangers, etc., and increase the airflow rate. , the effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

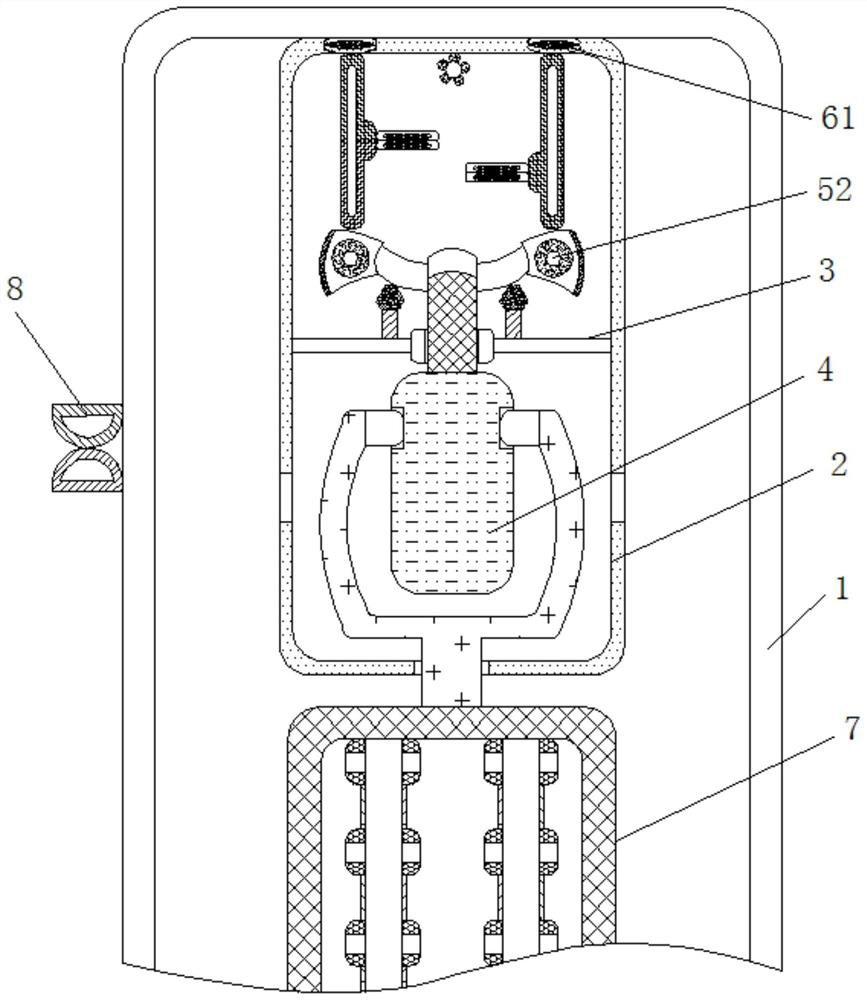

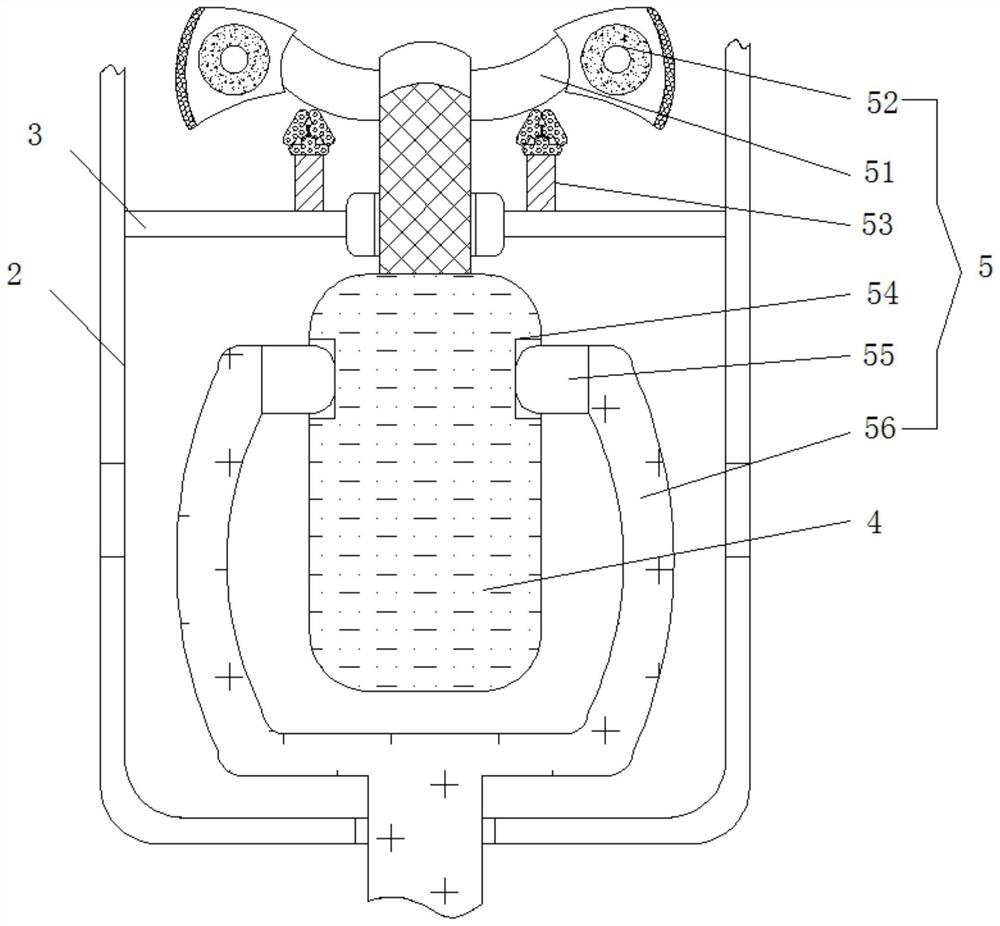

[0026] see Figure 1-3 , a lifting device for high-precision machining with a high safety factor, including a device housing 1 and a lifting table 7, the device housing 1 is fixedly connected with an installation housing 2, and the installation housing 2 is fixedly connected with a limiting plate 3 The inside of the limiting plate 3 is movably connected with a rotating main shaft 4, the outer side of the rotating main shaft 4 is fixedly connected with a movable sensing mechanism 5, the inside of the installation shell 2 is fixedly connected with a control mechanism 6, and the inside of the equipment housing 1 is movably connected with a lifting table 7;

[0027] The movable induction mechanism 5 includes a connecting rod 51, the outer side of the connecting rod 51 is fixedly connected with a rotating fin 52, the top of the limit plate 3 is fixedly connected with a magnetostrictive shaft 53, and the inside of the rotating main shaft 4 is provided with a wave groove 54, and the w...

Embodiment 2

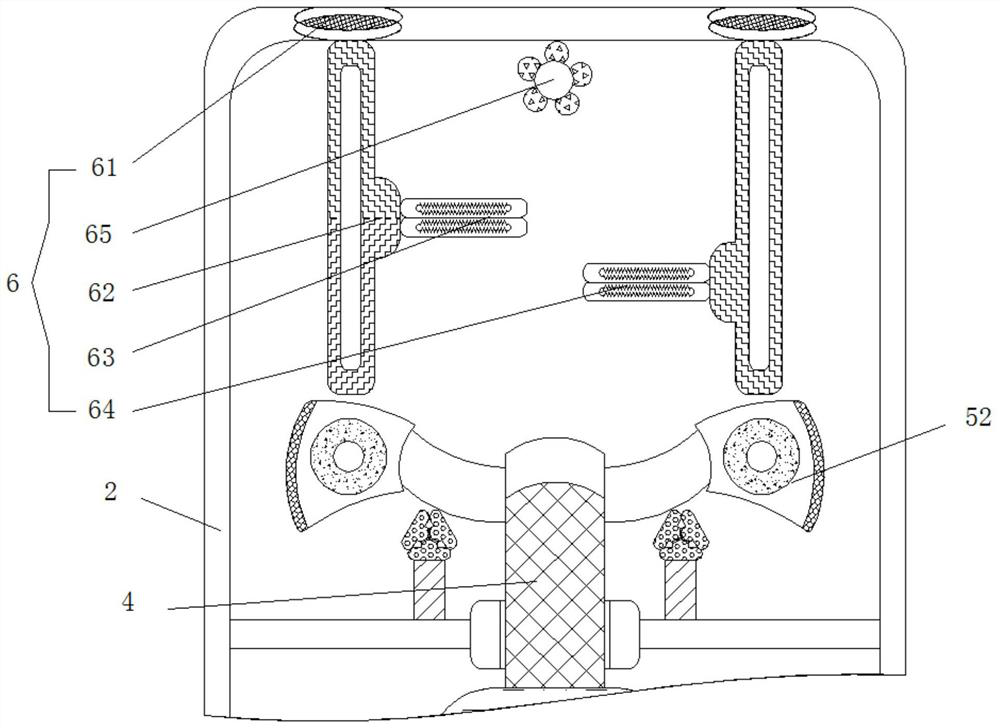

[0029] see figure 1 with Figure 4 , a lifting device for high-precision machining with a high safety factor, including a device housing 1 and a lifting table 7, the device housing 1 is fixedly connected with an installation housing 2, and the installation housing 2 is fixedly connected with a limiting plate 3 The inside of the limiting plate 3 is movably connected with a rotating main shaft 4, the outer side of the rotating main shaft 4 is fixedly connected with a movable sensing mechanism 5, the inside of the installation shell 2 is fixedly connected with a control mechanism 6, and the inside of the equipment housing 1 is movably connected with a lifting table 7;

[0030] The control mechanism 6 includes an elastic connector 61, the flexible plate 62 is fixedly connected to the bottom of the elastic connector 61, the positive plate 63 is fixedly connected to the inner side of the flexible plate 62, the negative plate 64 is fixedly connected to the inner side of the flexible ...

Embodiment 3

[0032] see Figure 1-4 , a lifting device for high-precision machining with a high safety factor, including a device housing 1 and a lifting table 7, the device housing 1 is fixedly connected with an installation housing 2, and the installation housing 2 is fixedly connected with a limiting plate 3 The inside of the limiting plate 3 is movably connected with a rotating main shaft 4, the outer side of the rotating main shaft 4 is fixedly connected with a movable sensing mechanism 5, the inside of the installation shell 2 is fixedly connected with a control mechanism 6, and the inside of the equipment housing 1 is movably connected with a lifting table 7;

[0033] The movable induction mechanism 5 includes a connecting rod 51, the outer side of the connecting rod 51 is fixedly connected with a rotating fin 52, the top of the limit plate 3 is fixedly connected with a magnetostrictive shaft 53, and the inside of the rotating main shaft 4 is provided with a wave groove 54, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com