A kind of imitation ant nest hydration ionic liquid gel platform and its preparation method and application

A technology of hydrated ions and liquid gels, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrolytes, etc., can solve the problems of wasting three-dimensional network formation space, low porosity, and limiting the transmission efficiency of gel materials, etc., and achieve excellent Ionic conductivity, ultra-high ionic conductivity, and the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

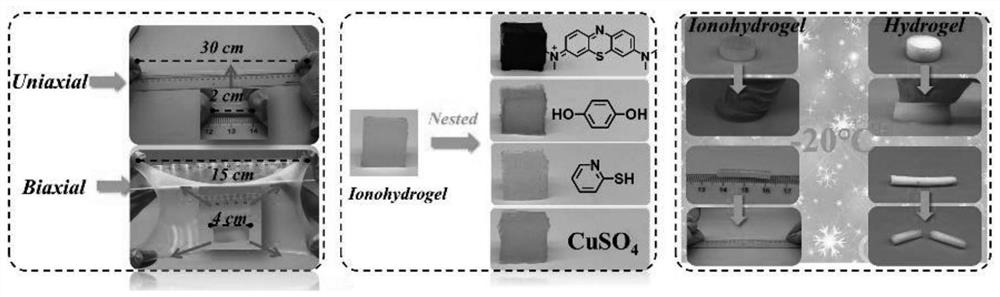

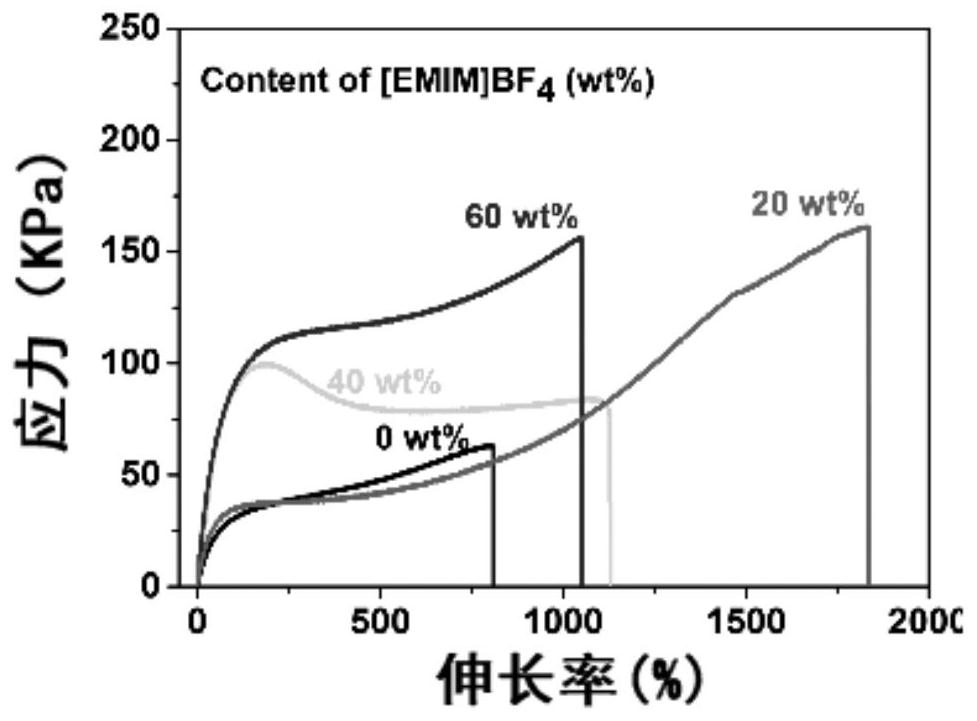

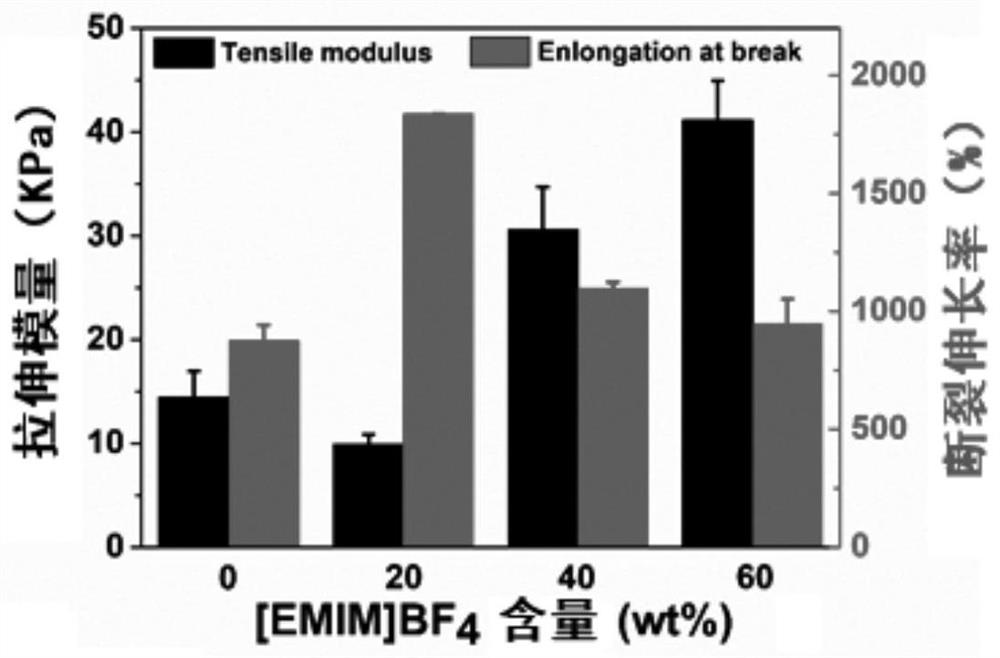

Embodiment 1

[0070] 200mg Acrylamide (AAm), 10mg Acrylated Chondroitin Sulfate (CSMA), 20mg NaHCO 3 and 10 μL of 2,2-diethoxyacetophenone (DEAP) were added to 1000 μL of hydrated ionic liquid (1-ethyl-3-methylimidazolium tetrafluoroborate ([EMIM][BF]) 4 ]): H 2 O=1:4), stir well until uniform. Subsequently, the solution was placed in a mold and placed under an ultraviolet lamp for 30 min to obtain a hydrated ionic liquid gel. Its compressive strength is 455.8KPa, which can withstand 90% of its own deformation; the tensile modulus is 9.9KPa, and the maximum tensile deformation is 1836.9%. The redox substance hydroquinone (HQ) was added to the 1 mol / L sulfuric acid solution, and its mass fraction was 5%, and the solution was fully stirred at 40° C. until the solid was completely dissolved. Then, the newly prepared hydrated ionic liquid gel was immersed in the etching solution under vigorous stirring. After the bubbles stopped generating, the etched hydrated ionic liquid gel was taken out,...

Embodiment 2

[0096] 200mg Acrylamide (AAm), 10mg Acrylated Chondroitin Sulfate (CSMA), 20mg NaHCO 3 and 10 μL of 2,2-diethoxyacetophenone (DEAP) were added to 1000 μL of hydrated ionic liquid (1-ethyl-3-methylimidazolium tetrafluoroborate ([EMIM][BF]) 4 ]): H 2 O=2:3), fully stir until uniform. The solution was then placed in a mold and placed under UV light for 30 min. The redox substance hydroquinone (HQ) was added to the 1 mol / L sulfuric acid solution, and its mass fraction was 5%, and the solution was fully stirred at 40° C. until the solid was completely dissolved. Then, the newly prepared hydrated ionic liquid gel was immersed in the etching solution under vigorous stirring. After the bubbles stopped generating, the etched hydrated ionic liquid gel was taken out, and the liquid on the surface of the gel was wiped off with a sponge to obtain An ant nest-like hydrated ionic liquid gel platform.

Embodiment 3

[0098] 200mg Acrylamide (AAm), 10mg Acrylated Chondroitin Sulfate (CSMA), 20mg NaHCO 3 and 10 μL of 2,2-diethoxyacetophenone (DEAP) were added to 1000 μL of hydrated ionic liquid (1-ethyl-3-methylimidazolium tetrafluoroborate ([EMIM][BF]) 4 ]): H 2 O=3:2), fully stir until uniform. The solution was then placed in a mold and placed under UV light for 30 min. The redox substance hydroquinone (HQ) was added to the 1 mol / L sulfuric acid solution, and its mass fraction was 5%, and the solution was fully stirred at 40° C. until the solid was completely dissolved. Then, the newly prepared hydrated ionic liquid gel was immersed in the etching solution under vigorous stirring. After the bubbles stopped generating, the etched hydrated ionic liquid gel was taken out, and the liquid on the surface of the gel was wiped off with a sponge to obtain An ant nest-like hydrated ionic liquid gel platform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com