Process method for obtaining standard substance of metal material

A technology of metal materials and process methods, which is applied in the direction of testing metals, analyzing materials, and material inspection products, etc., can solve the problems of chip surface pollution, oxidation, and short chips, etc., to improve chip hardness, save manpower, and reduce cutting feed Small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

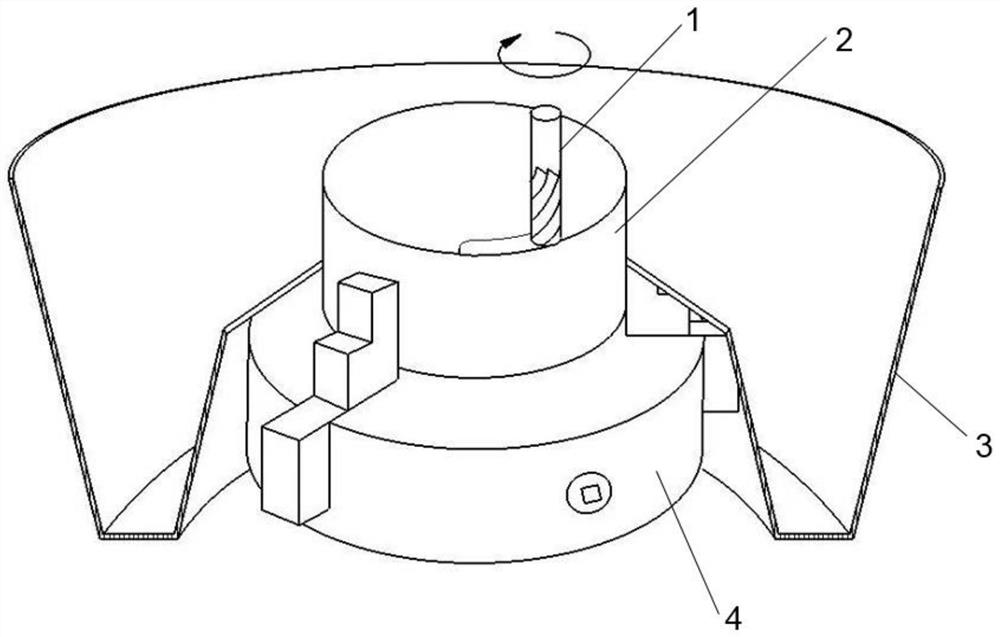

[0040] The metal material sample selected in this embodiment is a cylindrical titanium alloy TA1 with a diameter of 150 mm; the cutting adopts a diameter of 6 mm, the material is a tungsten-cobalt cemented carbide, and the cutter head is a four-blade flat end mill; the vertical processing used for cutting The central equipment model is FVP-800A.

[0041] The processing method of obtaining metal material standard substance in the present embodiment comprises the following steps:

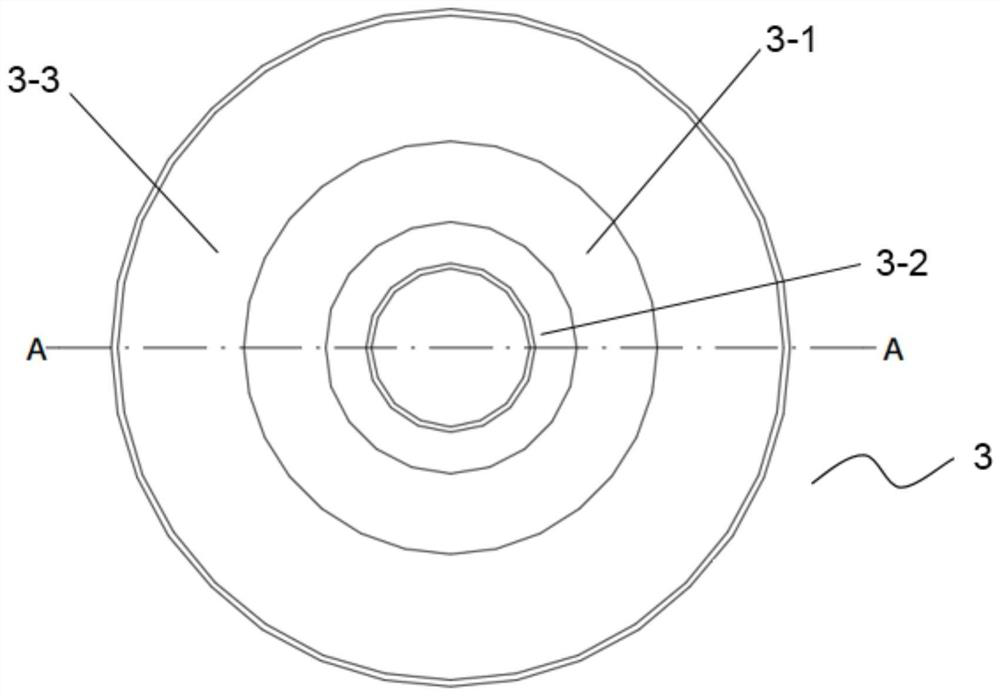

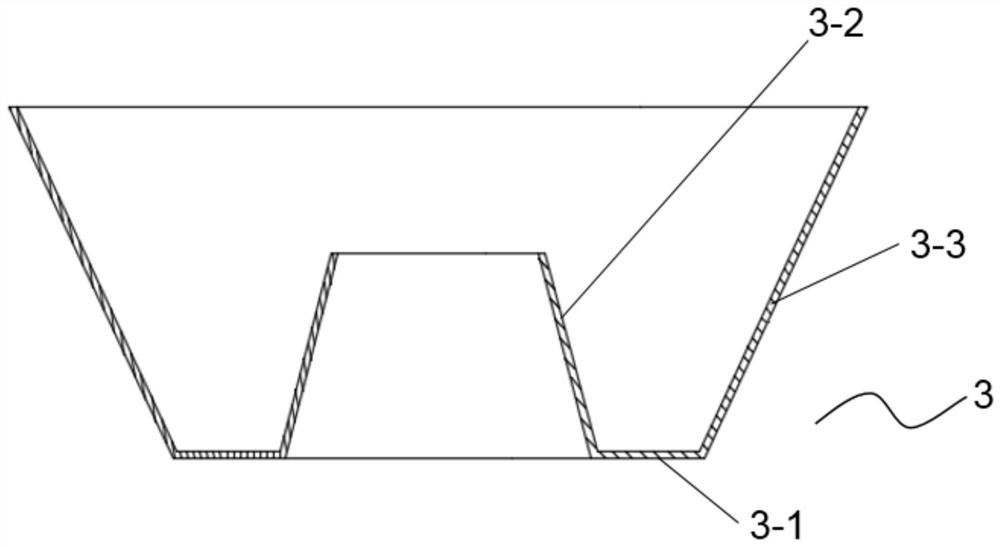

[0042] Step 1. Fix the three-jaw chuck 4 on the workbench of the vertical machining center, clamp the titanium alloy TA1 sample on the three-jaw chuck 4 and level it, and then place the inner wall plate 3 of the collector 3 The upper end of -2 is attached to the side wall of the three-jaw chuck 4, and the upper end of the inner wall plate 3-2 of the collector 3 is sleeved with a socket 5 matching the diameter of the cylindrical titanium alloy TA1 sample, and then the end mill Tool 1 is clamped on the...

Embodiment 2

[0051] The metal material sample selected in this embodiment is a cylindrical zirconium alloy N18 with a diameter of 150 mm; the cutting adopts an end mill with a diameter of 5 mm, the material is cermet, and the cutter head is a four-blade flat end mill; the model of the vertical machining center equipment used for cutting For FVP-800A.

[0052] The processing method of obtaining metal material standard substance in the present embodiment comprises the following steps:

[0053] Step 1. Fix the three-jaw chuck 4 on the workbench of the vertical machining center, clamp the zirconium alloy N18 sample on the three-jaw chuck 4 and perform leveling, and then close the inner surface of the outer wall collector 3 The upper end of the coaming plate 3-2 is attached to the side wall of the three-jaw chuck 4, and the upper end of the inner coaming plate 3-2 of the collector 3 is sleeved with a socket 5 matching the diameter of the cylindrical zirconium alloy N18 sample, and then Clamp t...

Embodiment 3

[0062] The metal material sample selected in this embodiment is a cylindrical hafnium alloy H01 with a diameter of 150 mm; the cutting adopts an end mill with a diameter of 4 mm, the material is tungsten-cobalt cemented carbide, and the cutter head is a four-blade flat end mill; the vertical processing used for cutting The central equipment model is FVP-800A.

[0063] The processing method of obtaining metal material standard substance in the present embodiment comprises the following steps:

[0064] Step 1. Fix the three-jaw chuck 4 on the workbench of the vertical machining center, clamp the hafnium alloy H01 sample on the three-jaw chuck 4 and level it, and then place the inner wall plate 3 of the collector 3 -2 The upper end is attached to the side wall of the three-jaw chuck 4, and the sleeve 5 matching the diameter of the cylindrical hafnium alloy H01 sample is socketed on the upper end of the inner wall plate 3-2 of the collector 3, and then the end mill Tool 1 is clam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap