High-stability concentrated tea extracting solution and extracting method

A technology with high stability and extraction method, which is applied in tea extraction, pre-extraction tea treatment, tea, etc., can solve the problems of poor stability, easy aggregation and settlement, etc., to reduce long-term storage deterioration, not easy to coagulate and deteriorate, The effect of strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

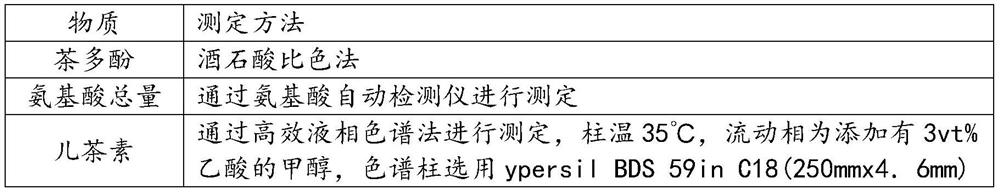

Image

Examples

Embodiment 1~20

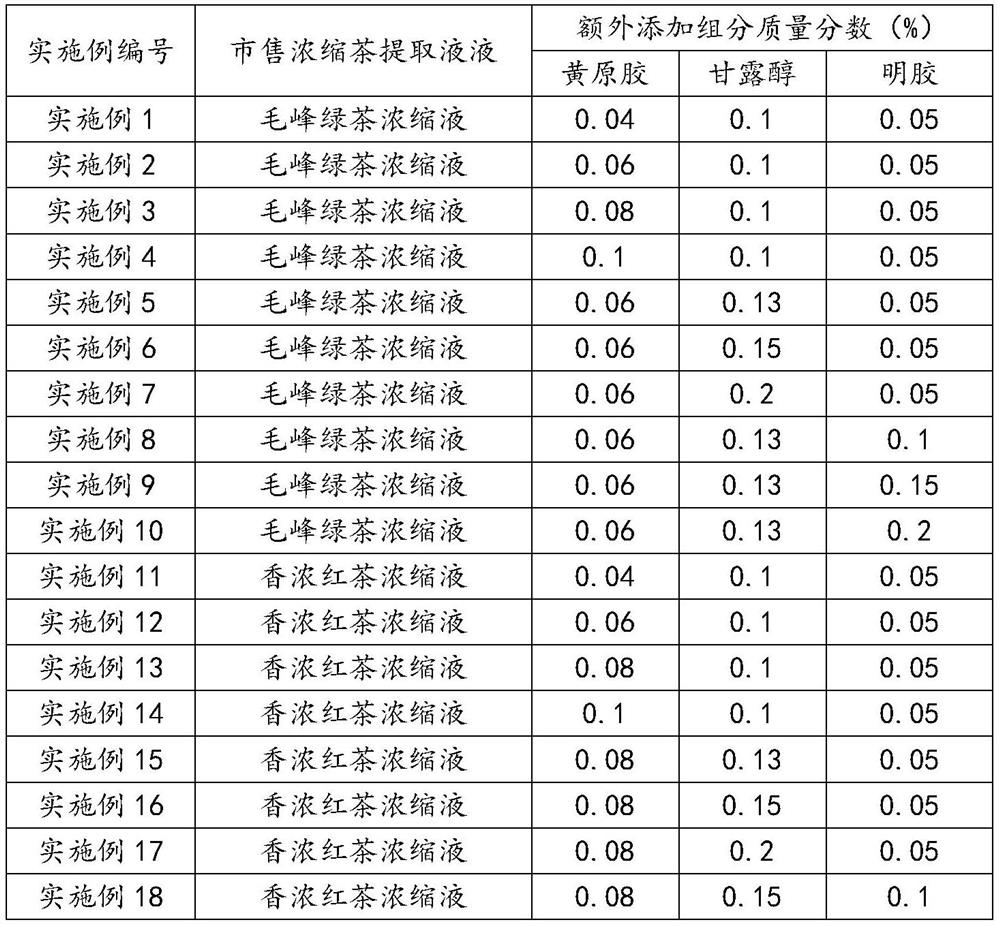

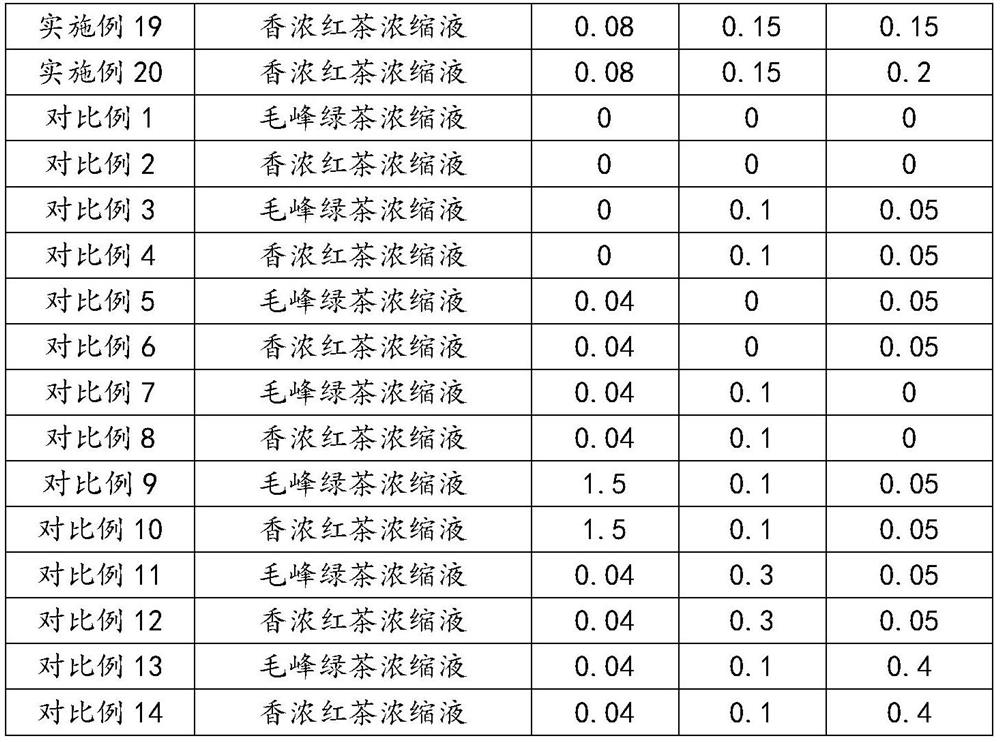

[0053] Examples 1-20, a concentrated tea extract with high stability, on the basis of the existing commercially available concentrated tea extract, additionally added xanthan gum, mannitol and gelatin. The selection of the commercially available concentrated tea extract and the specific dosages of xanthan gum, mannitol and gelatin are shown in Table 3.

[0054] In addition, comparative examples 1 to 20 are set up, all of which are concentrated tea extracts obtained by adding the components with mass fractions shown in Table 3 to commercially available concentrated tea extracts.

[0055] Material proportioning in table 3, embodiment 1~20

[0056]

[0057]

[0058] Experiment 1 was carried out on the above-mentioned embodiment, and the results are shown in Table 4.

[0059] Table 4, Examples 1-20 and comparative examples 1-14 stability test results

[0060]

[0061] The above experimental data can be verified. In this application, the composite system of xanthan gum, ...

Embodiment 21~32

[0064] Examples 21-32 are concentrated tea extracts with high stability, which are obtained by adding the ingredients shown in Table 5 on the basis of Example 8.

[0065] Table 5. Further adjustment plan of Maofeng green tea concentrate

[0066]

[0067] Examples 33-44 are highly stable concentrated tea extracts, which are obtained based on Example 19 by adding the ingredients shown in Table 6.

[0068] Table 6. Further adjustment plan for fragrant black tea concentrate

[0069]

[0070] Experiment 1 was carried out on Examples 21-44, and the results are shown in Table 7.

[0071] Table 7, embodiment 21~44 stability experiment results

[0072]

[0073] In the above-mentioned embodiment, further optimization was carried out, and the above-mentioned result was obtained. Among them, in Examples 21 to 24 and Examples 33 to 36, β-cyclodextrin is added, and β-cyclodextrin can accommodate and coat some molecules of medium molecular weight in the concentrated tea extract, ...

Embodiment 45

[0077] Example 45, high stability concentrated tea extract, its preparation steps are as follows:

[0078] S1. Break the tea leaves, and then process them under microwaves. Corresponding to each kilogram of tea leaves, use 120kw microwaves to process them for 20 seconds to obtain preliminary processed tea leaves;

[0079] S2. Add the preliminarily treated tea leaves to water in an amount of 0.3kg / L, mix the first enzyme with a concentration of 1g / L, control the temperature at 34°C, enzymatically treat for 80min, and then separate by suction filtration to obtain the first mixed solution and first filter residue;

[0080] S3. Add the first filter residue to water in an amount of 0.5 kg / mL, add a second mixed enzyme at a concentration of 1 g / L, perform enzymatic hydrolysis at 37° C. for 45 minutes, and filter out solid residues therein to obtain a second mixed solution;

[0081] S4. Combine the first mixed solution and the second mixed solution, heat to 90°C to inactivate the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com