Flotation reagent and bismuth-zinc-sulfur polymetallic sulfide ore flotation separation method

A reagent and flotation technology, applied in flotation, solid separation, etc., can solve the problems of increasing the difficulty of separating bismuth, zinc and sulfur, the separation effect needs to be improved, and high sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

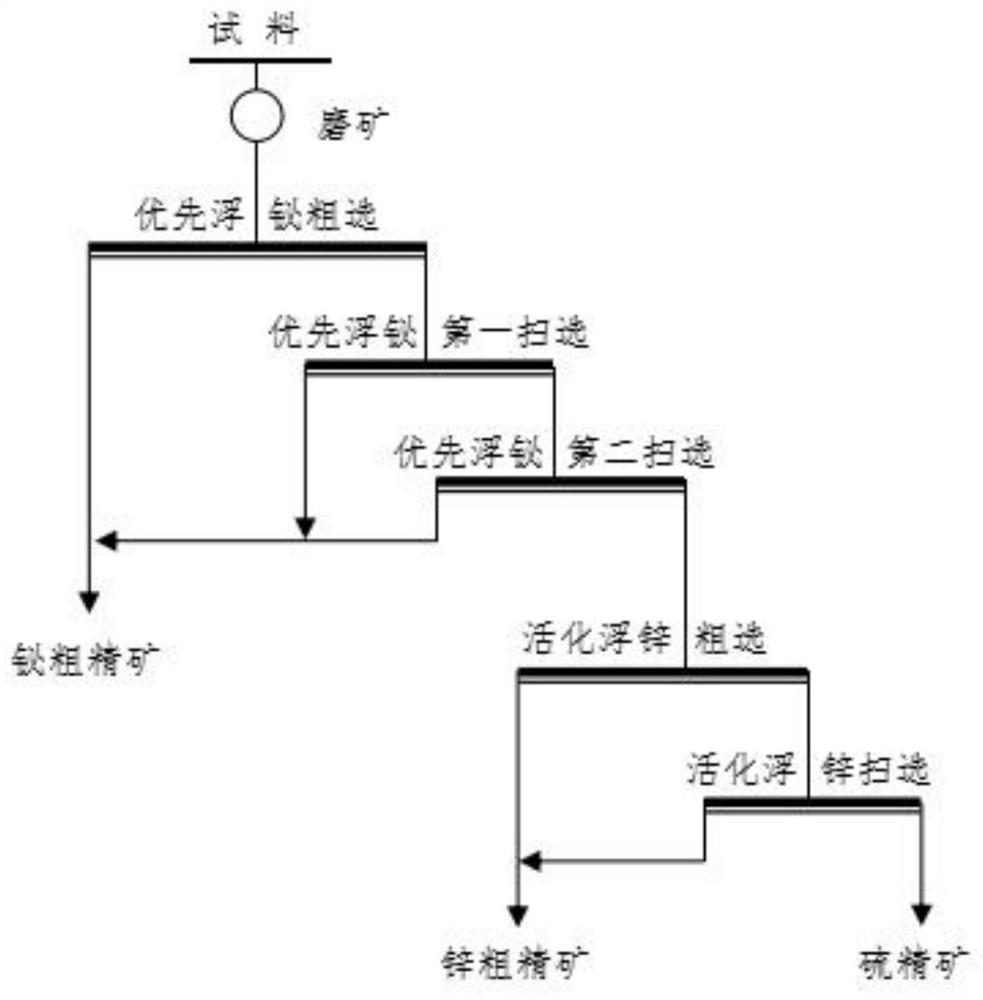

Method used

Image

Examples

Embodiment 1

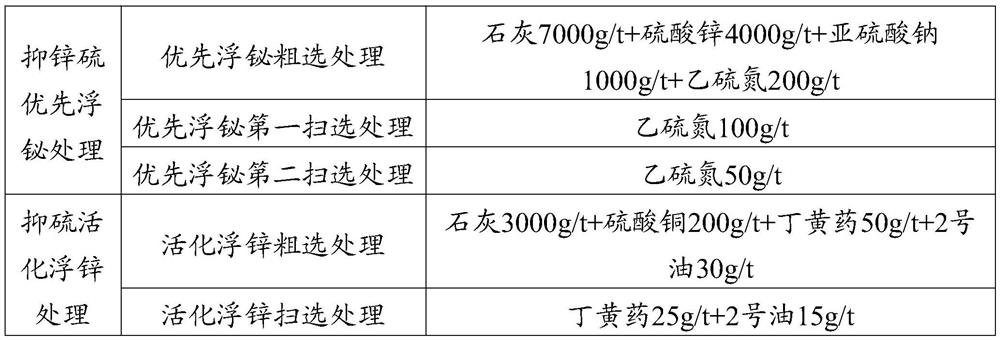

[0056] According to the method of comparative example 1, bismuth-zinc-sulfur polymetallic sulfide ore is carried out flotation separation, the difference is:

[0057] The medicament used in the priority floating bismuth roughing treatment in step (2) is 8000g / t of lime, 300g / t of sodium thioglycolate and 160g / t of ethionazide, and the medicament used in the first scavenging process of priority floating bismuth is ethionazol 80g / t, the agent used in the second sweeping treatment of preferential floating bismuth is ethionyl 40g / t;

[0058] The medicament used in the roughing treatment of activated zinc floating in step (3) is copper sulfate 200g / t, 40g / t and No. 2 oil 30g / t, and the medicament used in the scavenging process of activated floating zinc is 20g fenugreek / t and No. 2 oil 15g / t.

[0059] See Table 2 for the types and dosages of medicaments in each step in this embodiment.

[0060] Medicament type and consumption in table 2 embodiment 1

[0061]

[0062] The tes...

Embodiment 2

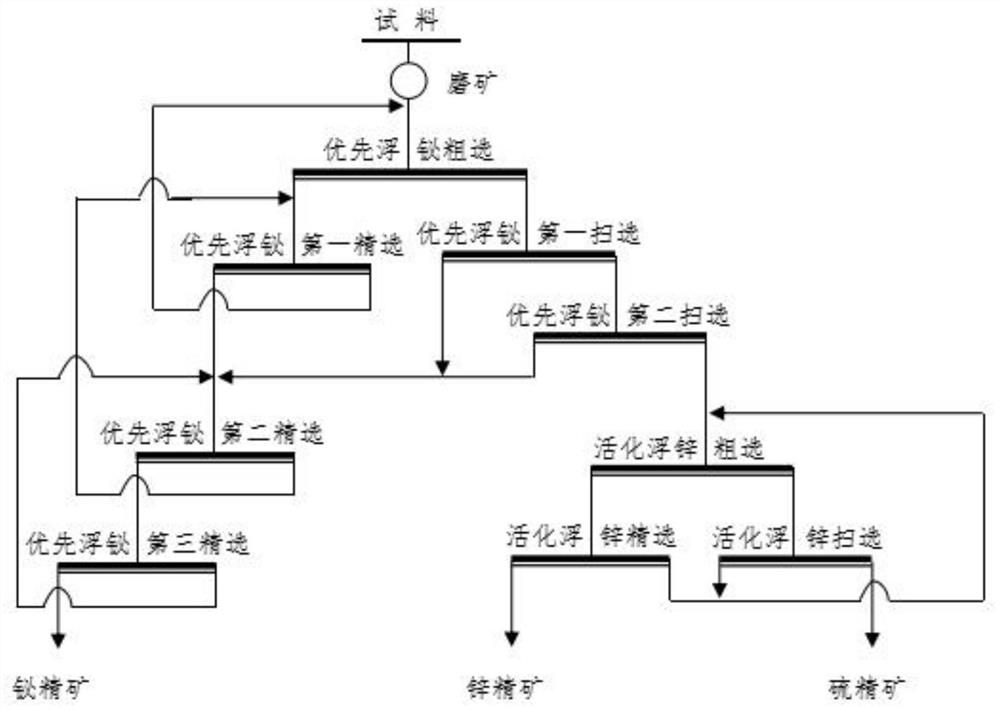

[0067] according to figure 2 Shown flow process (closed circuit test), bismuth-zinc-sulfur polymetallic sulfide ore is carried out flotation separation, comprises the following steps:

[0068] (1) After the bismuth-zinc-sulfur polymetallic sulfide ore is crushed to -2mm, it is ground by a ball mill until the ore whose grinding fineness is -0.074mm accounts for 70% of the total ore, and the ore pulp to be selected is obtained; The content of Bi in the bismuth-zinc-sulfur polymetallic sulfide ore is 1.01%, the content of Zn is 4.66%, and the content of S is 43.56%;

[0069](2) add lime 8000g / t, sodium mercaptoacetate 300g / t and ethyl disulfide nitrogen 160g / t in the described ore pulp to be selected, carry out preferential floating bismuth roughing treatment, obtain roughing concentrate and roughing tailings; The rougher concentrate is subjected to the first beneficiation treatment of preferentially floating bismuth (i.e. the first blank beneficiation treatment) to obtain the ...

Embodiment 3

[0080] According to the method for embodiment 2, bismuth zinc sulfur polymetallic sulfide ore is carried out flotation separation, difference is:

[0081] In the bismuth-zinc-sulfur polymetallic sulfide ore described in step (1), the Bi content is 0.93%, the Zn content is 4.90%, and the S content is 42.68%. 65%;

[0082] The consumption of lime is 6000g / t, the consumption of ethyl disulfide nitrogen in the described priority floating bismuth roughing process of step (2) is 200g / t, and the consumption of described priority floating bismuth first scavenging process is 100g / t t, the amount of ethylsulfide nitrogen in the second scavenging treatment of the priority floating bismuth is 50g / t;

[0083] The consumption of sodium thioglycolate is 150g / t in the second concentrating treatment of the priority floating bismuth described in step (3), and 20g / t of ethyl disulfide is added simultaneously; In the third concentrating treatment of the priority floating bismuth, no ethyl disulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com