Waste lithium ion power battery pack shell cutting system

A power battery pack and cutting system technology, applied in secondary batteries, battery recycling, circuits, etc., can solve problems such as potential safety hazards, inability to cool down the cutting disc, and affecting the service life of the cutting disc, so as to improve the service life and increase the cooling speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

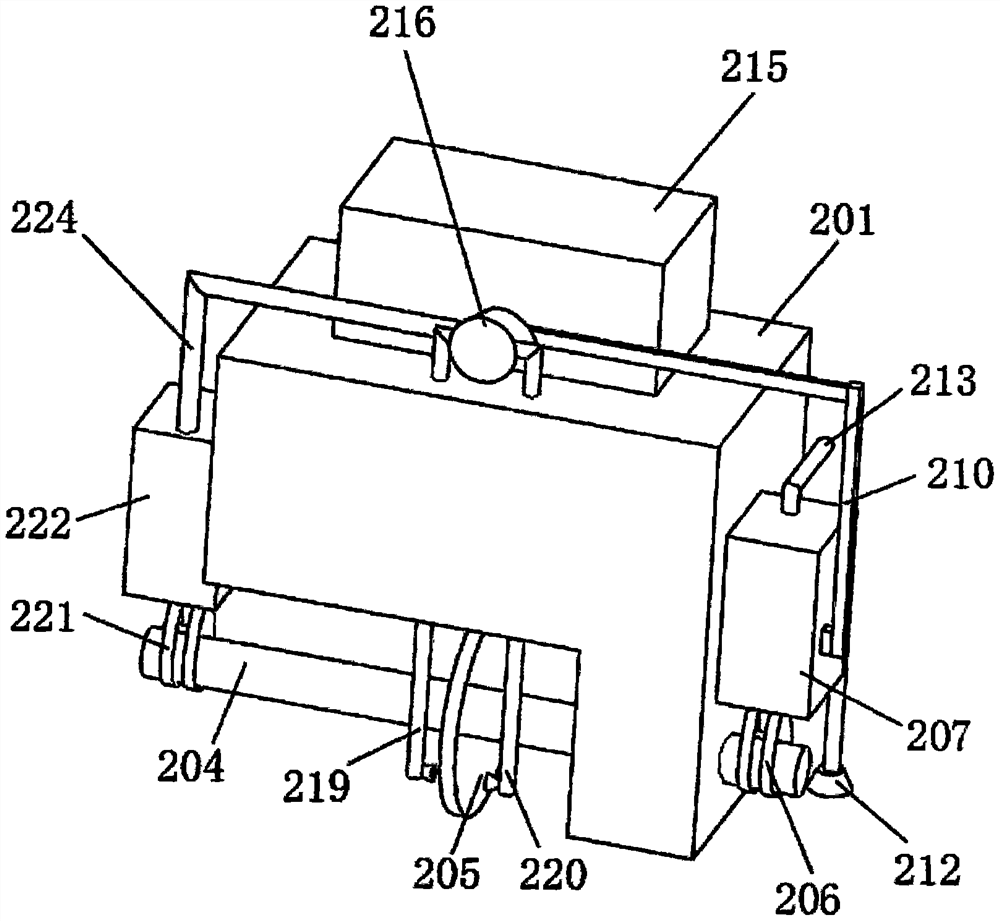

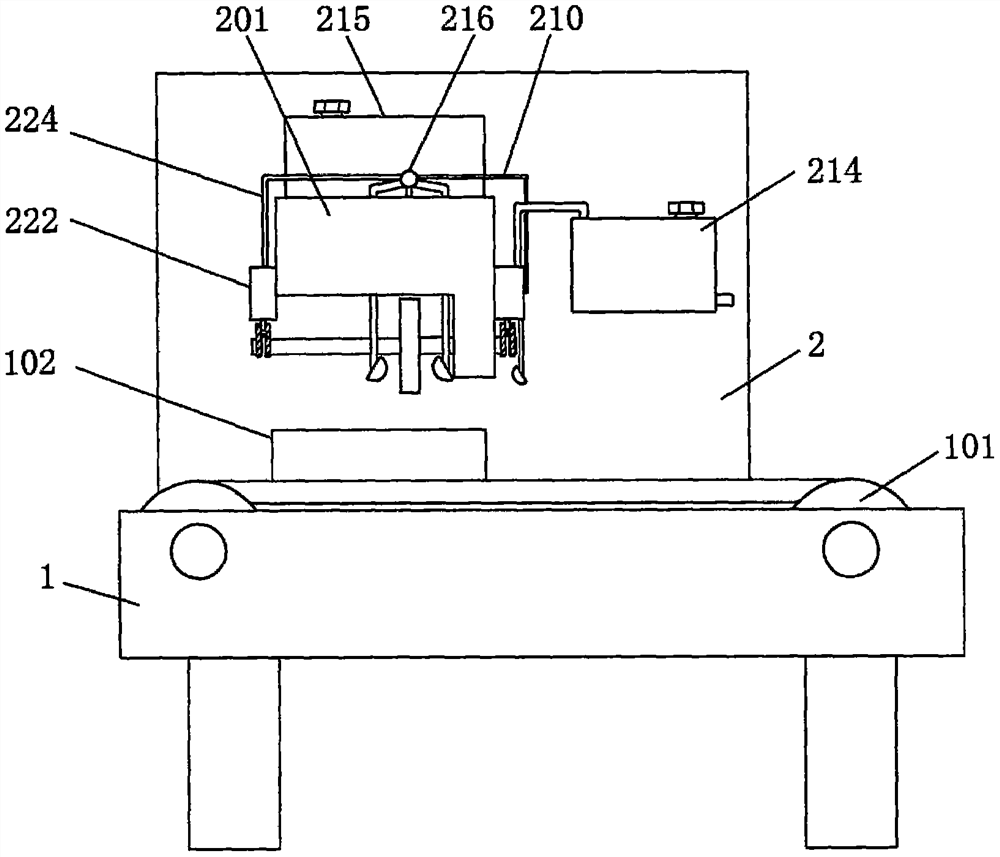

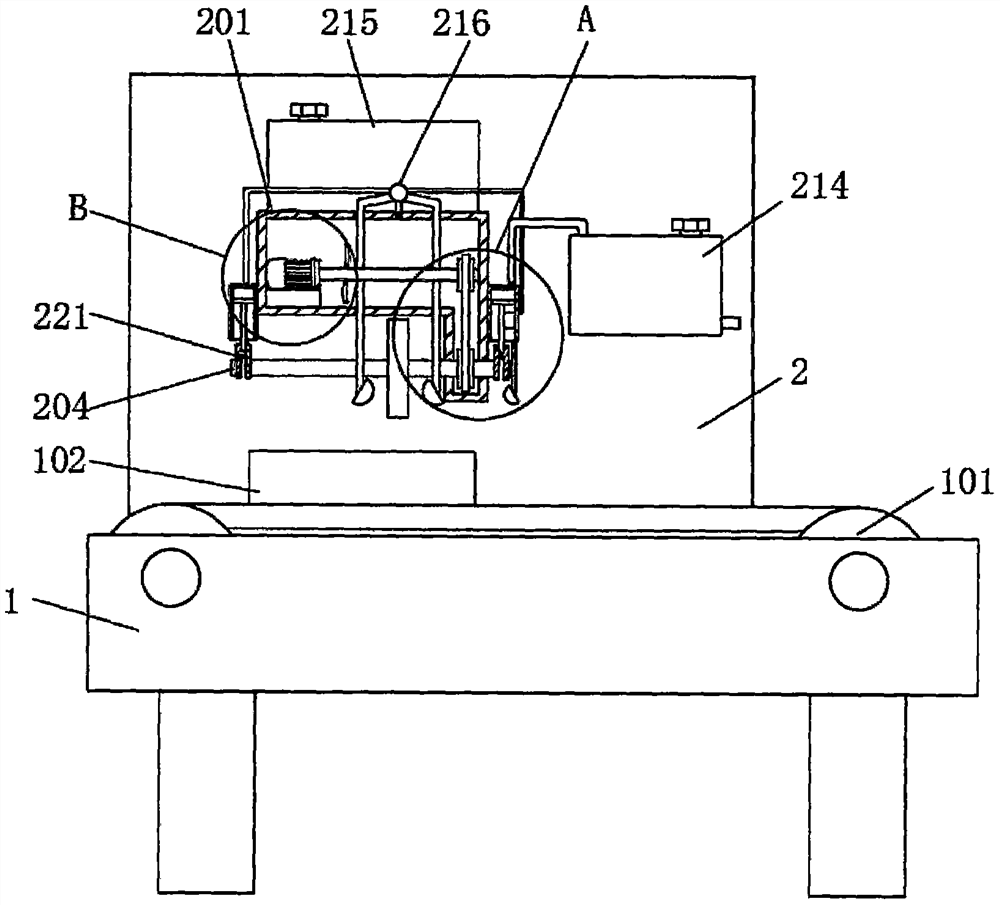

[0032] refer to Figure 1-7 , a waste lithium-ion power battery case cutting system, including a workbench 1, a conveyor belt 101 and a battery pack body 102, the conveyor belt 101 is set on the workbench 1, the battery pack body 102 is placed on the conveyor belt 101, and also includes: a riser 2. It is fixedly connected to the workbench 1; the connecting shell 201 is fixedly connected to the side wall of the riser 2; the cutting mechanism is set in the connecting shell 201 for cutting the battery pack body 102; the cooling mechanism is set in the connecting shell 201 on, used to cool down the cutting device; the heat conduction mechanism is arranged on the connecting shell 201, and is used to conduct the heat generated by cutting to the cooling mechanism; the motor 202 is fixedly connected in the connecting shell 201; it is used to drive the cutting mechanism, cool down Mechanism and heat conduction mechanism work.

[0033] When performing cutting work, the battery pack bod...

Embodiment 2

[0035] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 7, is basically the same as Embodiment 1, furthermore, in order to cut the battery pack body 102, the cutting mechanism includes a first heat conducting rod 204 and a cutting disc 205, the output end of the motor 202 is fixedly connected with a rotating shaft 203, and the first heat conducting rod 204 Rotationally connected to the bottom of the connecting shell 201, the first pulley is connected on the rotating shaft 203, the second pulley matched with the first pulley is connected on the first heat conducting rod 204, the first pulley and the second pulley A belt is connected, and the cutting disc 205 is fixedly connected to the first heat conducting rod 204 .

[0036] When cutting, turn on the motor 202, and the rotating shaft 203 on the output end of the motor 202 drives the second pulley to rotate through the first pulley, thereby driving the first heat conducting rod 204 to rotate, an...

Embodiment 3

[0038] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 7 , is basically the same as Embodiment 1, furthermore, in order to transfer the heat generated by cutting to the cooling mechanism, the heat conduction mechanism includes a first crankshaft 206, a first connection box 207, a heat conduction plate 209 and a second heat conduction rod 210, the first The crankshaft 206 is fixedly connected to the first heat conducting rod 204, the first connection box 207 is fixedly connected to the side wall of the connection shell 201, and the outer wall of the first crankshaft 206 is rotatably connected to the first connecting rod 208, which is far away from the first connecting rod 208. One end of a crankshaft 206 is connected in the first connection box 207, the heat conduction plate 209 is fixedly connected in the first connection box 207, the outer wall of the first connection rod 208 is attached to the outer wall of the heat conduction plate 209, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com