Gap-removing and bubble-removing type mutual inductor glue sealing process

A transformer and plastic sealing technology, applied in the field of transformers, can solve the problems of short service life of transformers, serious discharge phenomenon of transformers, and potential safety hazards, and achieve the effects of avoiding discharge phenomena, not easy to loosen, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

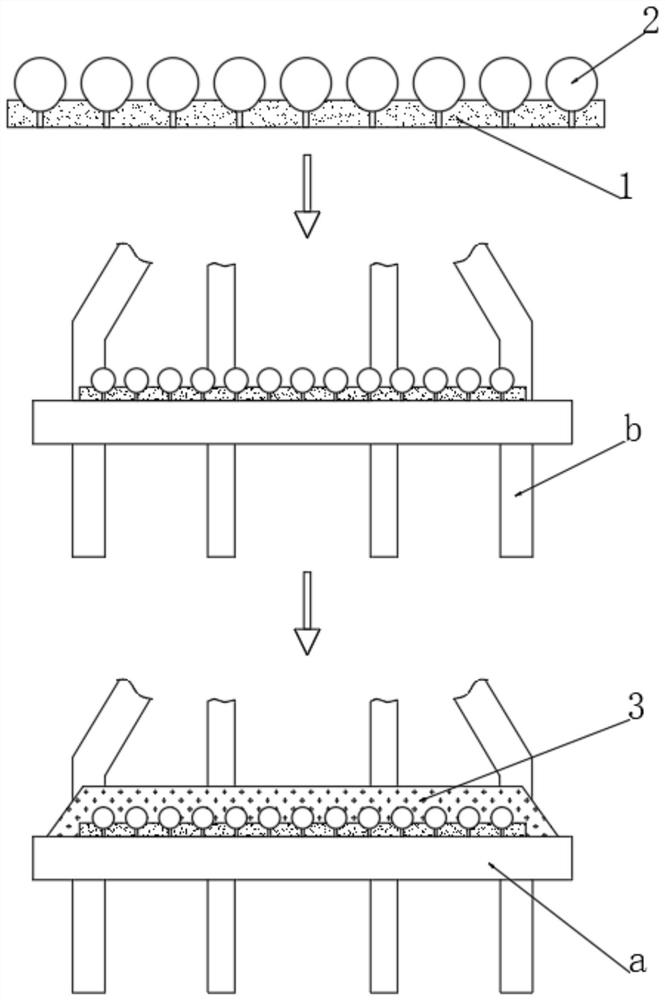

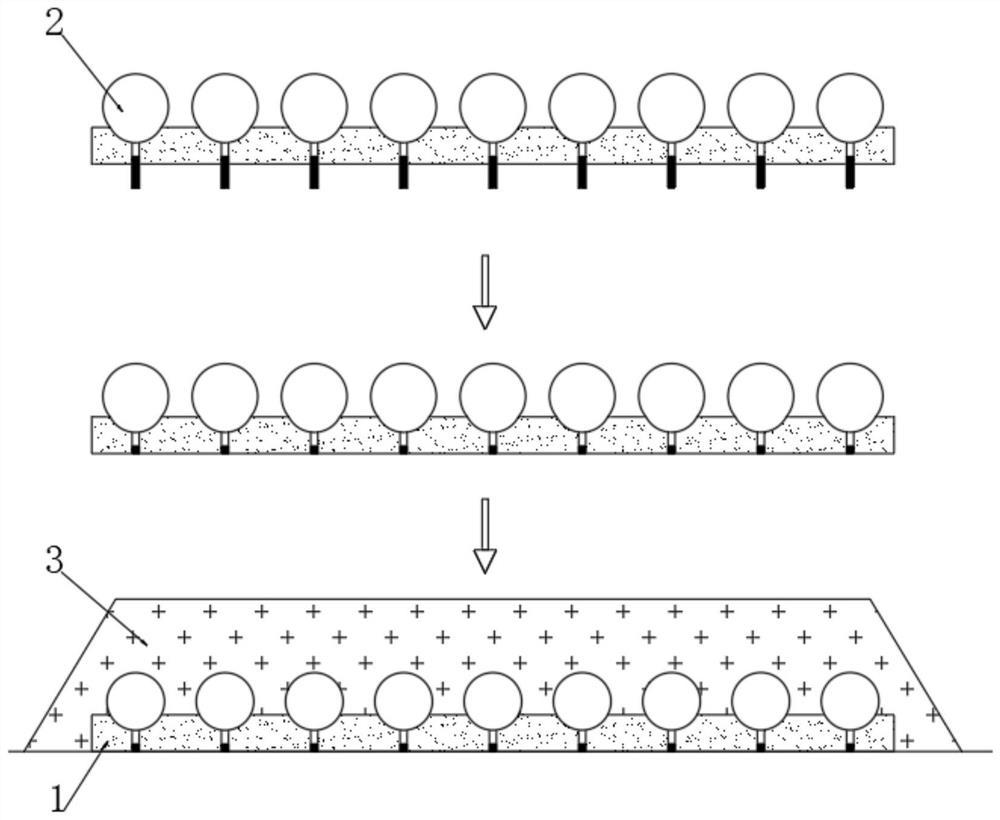

[0046] see Figure 1-2 , in the figure, a represents the bottom plate, and b represents the part where the winding is in contact with the bottom plate. A seam-removing and bubble-removing type transformer glue sealing process includes the following steps:

[0047] S1. First make the epoxy resin heat shrinkable board 1, and then evenly lay the epoxy resin heat shrinkable board 1 on the bottom plate of the transformer around the winding and the shell;

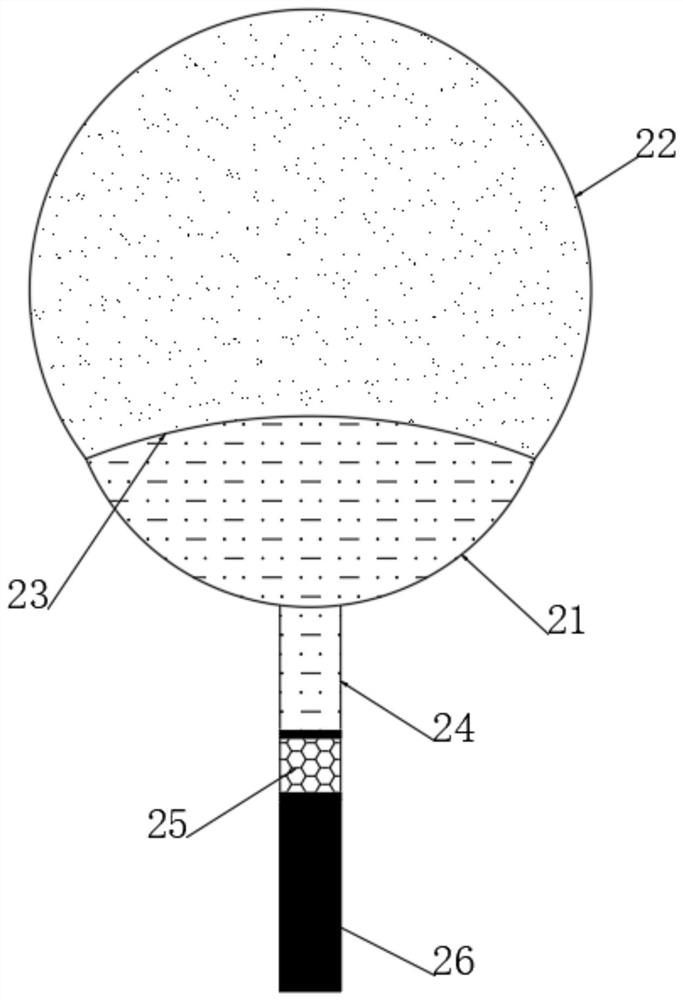

[0048] S2. Then pour molten epoxy resin onto the top of the epoxy resin heat-shrinkable plate 1, and heat the bottom plate at the same time, and the heating will soften or melt the bottom of the epoxy resin heat-shrinkable plate 1, so that the degree of bonding between the epoxy resin heat-shrinkable plate 1 and the bottom plate is improved. Well, let the bottom of the epoxy resin heat shrinkable board 1 be heated and softened, and the high-permeability glue inside overflows and infiltrates between the epoxy resin heat shrinkable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com