Efficient edge collecting machine for degradable plastic film production and degradable plastic film production process

A technology of plastic film and edger, which is applied in the fields of plastic recycling, thin material processing, recycling technology, etc., can solve the problems of long time consumption, low winding speed, and insufficient function of edger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

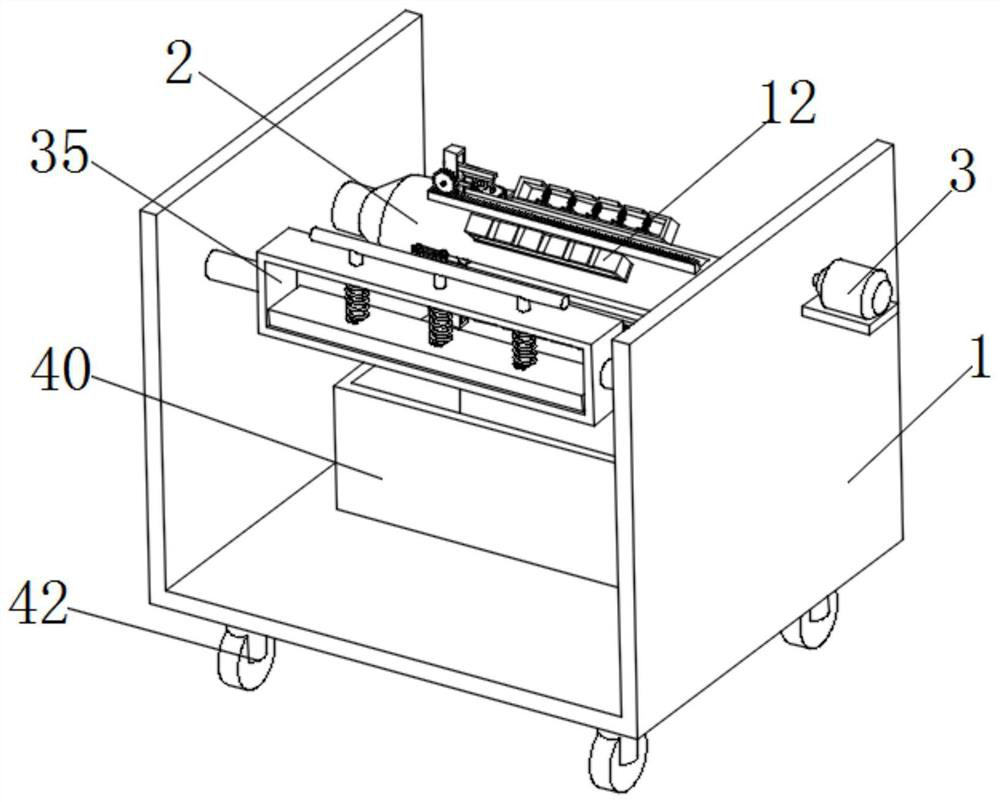

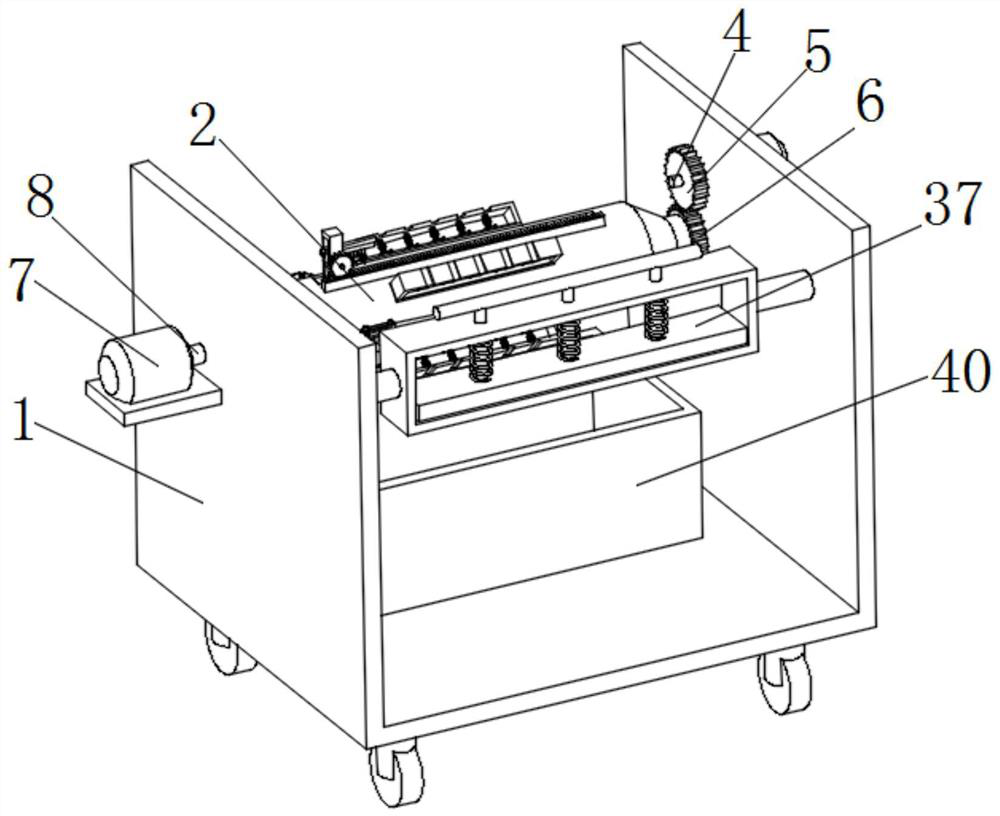

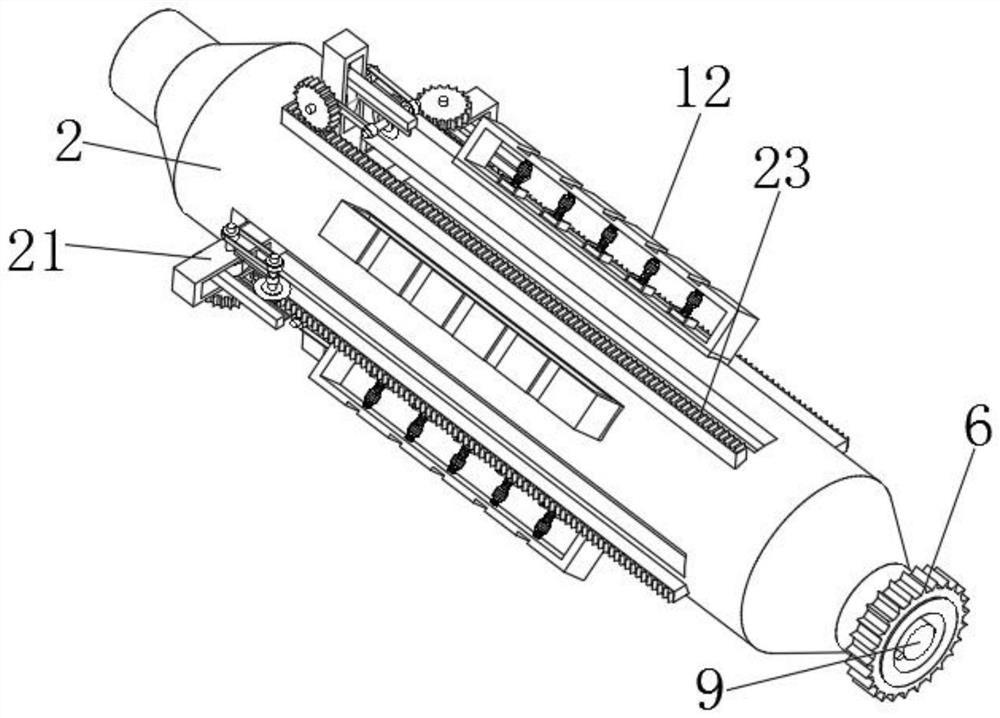

[0043] Example: Reference Figure 1-8 The high-efficiency trimming machine for the production of degradable plastic film shown includes a frame 1, and the inside of the frame 1 is rotatably connected to a reel 2, and a plurality of evenly distributed waste fixing parts are installed on the side wall of the reel 2 , both sides of the frame 1 are fixedly connected with mounting plates, the mounting plate can be any flat plate in the prior art, such as a metal plate, and the two mounting plates can be fixedly connected to both sides of the frame 1 by welding.

[0044] The two mounting plates are respectively fixedly connected, and the winding motor 3 can be any driving motor in the prior art, such as a driving motor winding motor 3 and a cutting motor 7 whose model is 5IK120RGN, and the cutting motor 7 can be a driving motor of the prior art Any one of the servo motors, such as the servo motor model 80st-m02430, the winding motor 3 and the cutting motor 7 can be fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com