Full-rubber-powder elastomer material capable of being repeatedly processed and preparation method of full-rubber-powder elastomer material

An elastomer material and a technology for repeated processing, which is applied in the field of preparation of all rubber powder elastomer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) 40 mesh waste rubber powder and tetramethylpiperidine nitroxide free radical phosphite triester are according to the ratio of mass and number of 100:10 on the open mill and mixed evenly at room temperature to obtain the mixed rubber, and the mixed rubber was Thermal crosslinking at 140°C for 30 minutes, followed by cold pressing at room temperature for 5 minutes to obtain a full-rubber powder elastomer with repeatable processing properties.

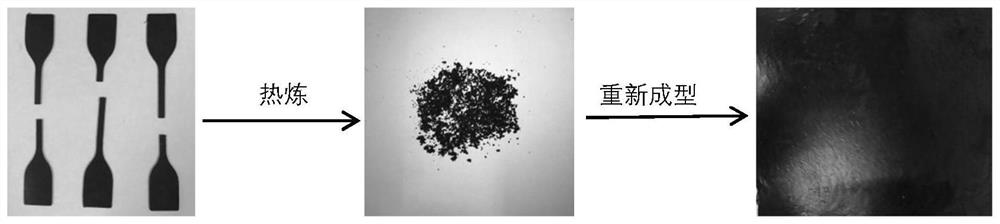

[0029] (2) The repeated processing of the elastomer material is to heat the used all-rubber powder elastomer into powder on a 140°C open mill, and then open the mill at room temperature to produce sheets, and then place it on a flat vulcanizer at 140°C Heat cross-linking for 30 minutes, and finally cold pressing at room temperature for 5 minutes to obtain a full rubber powder elastomer that can be repeatedly processed. The repeated processing process is as follows: figure 1 shown.

[0030] (3) The tensile test experiment shows...

Embodiment 2

[0032] (1) 120 mesh waste rubber powder and 1,10-sebacic acid-4,4'-bis(1-oxidation-2,2,6,6-tetramethyl)piperidinate are prepared according to the ratio of parts by mass Mix 100:1 on an open mill at room temperature to obtain a compound rubber, heat crosslink the compound rubber at 120°C for 60 minutes, and then cold press it at room temperature for 5 minutes to obtain a full-rubber powder elastomer with repeatable processing properties.

[0033] (2) The repeated processing of the elastomer material is to heat the used all-rubber powder elastomer on a 120°C open mill to form a powder, and then roll out the sheet at room temperature, and then place it on a flat vulcanizer at 120°C Heat cross-linking for 60 minutes, and finally cold pressing at room temperature for 5 minutes to obtain a repeat-processed full rubber powder elastomer. The repeat process is as follows: figure 1 shown.

[0034] (3) The full-rubber powder elastic body obtained in Example 2 also has good mechanical stre...

Embodiment 3

[0036] (1) First synthesize a compound containing two stable nitroxide free radicals: dissolve 17.2g of 4-hydroxyl-2,2,6,6-tetramethylpiperidine-1-oxyl free radical in 20ml of toluene, drop slowly Add 11.1 g of isophorone diisocyanate, place the reaction at 80° C., and react for 8 hours under a nitrogen atmosphere to obtain a compound containing two stable nitroxide radicals.

[0037] (2) Mix the 10-mesh waste rubber powder and the synthesized compound containing two stable nitrogen-oxygen free radicals according to the ratio of mass and number of 100:15 on the open mill at room temperature to obtain the mixed rubber, and mix the mixed rubber at 180 Thermal crosslinking at ℃ for 30 minutes, and then cold pressing at room temperature for 5 minutes to obtain a full-rubber powder elastomer with repeatable processing properties.

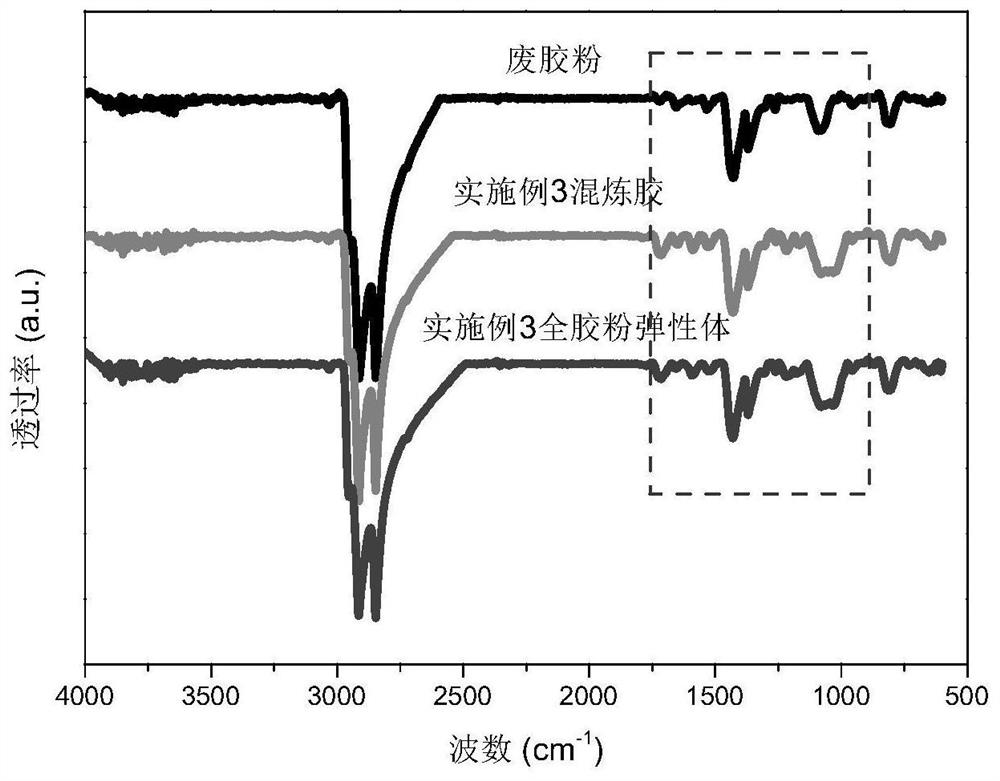

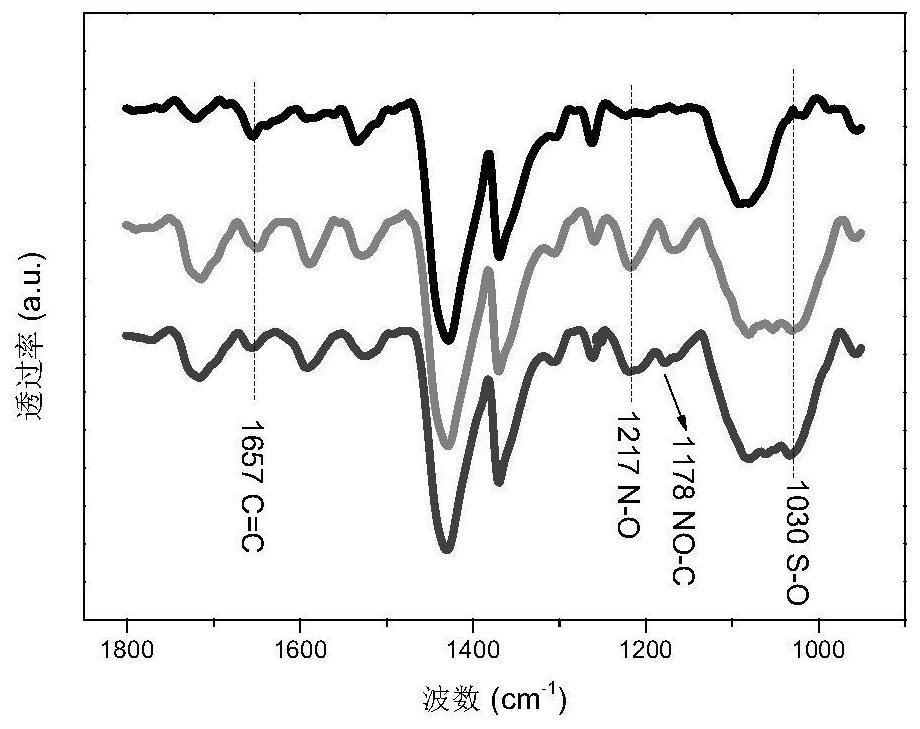

[0038] (3) The infrared spectrogram of waste rubber powder, rubber compound in embodiment 3 and full rubber powder elastomer material in embodiment 3 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com