Solid state fermentation device and solid state fermentation method

A solid-state fermentation and fermenter technology, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning hollow objects, etc., can solve the problem that the temperature of the upper and lower layers and the temperature of the inner and outer layers are not the same, affecting product quality stability and typical style, fermentation Solve the problems of different quality of fermented grains, achieve good practical value, improve the degree of production automation, and promote the effect of anaerobic fermentation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

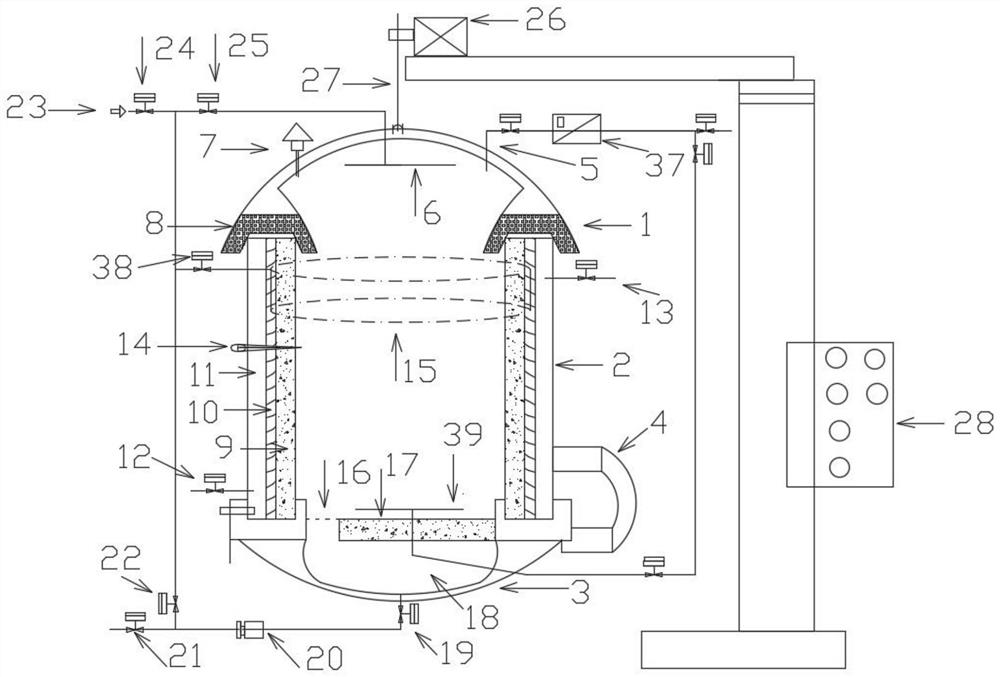

[0059] The solid-state fermentation device in the present invention includes a cover plate 1, a fermentation tank 2, a bottom cover tank 3, a connecting device 4, a lifting device 26, a water pump 20, a vacuuming device 37, a squeezing device 29 and a cleaning device 31.

[0060] Among them, the cover plate 1 is a circular arched heat-preservation stainless steel cover plate with a diameter of 1.5 meters. The cover is provided with an annular shower pipe as the shower device 6, and is connected with the external pipeline, and a vacuum suction pipe 5 is provided on its circular arched cover, and is connected with the vacuum device 37.

[0061] Among them, the fermentation tank 2 is a cylindrical stainless steel tank body with a diameter of 1.5 meters and a height of about 2.5 meters. The innermost side is a pit mud casing 9, the middle is a water-retaining spongy casing 10, and the outer side is an outer casing with a thermal insulation cavity. 11. The thickness of the three-la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com