Brick regenerated by using construction waste

A technology for construction waste and recycled bricks, which is applied in the field of resource utilization of construction waste, can solve the problems of looseness, low strength, and low apparent density of pavement bricks, and achieves the improvement of mechanical strength, service life and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

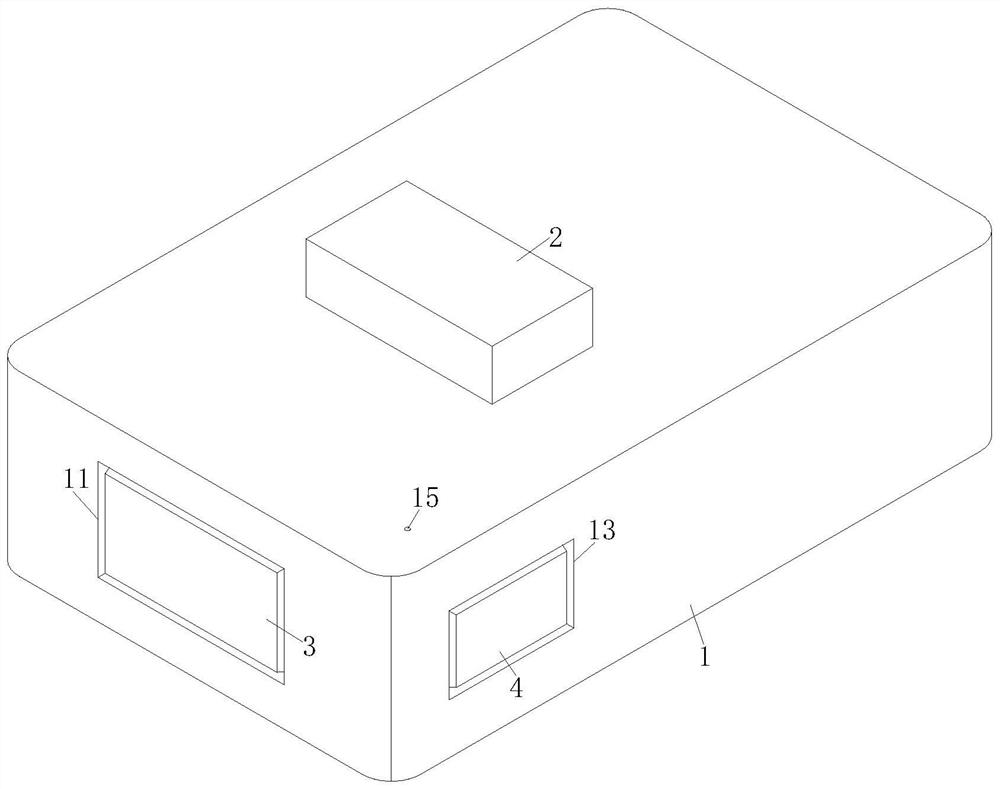

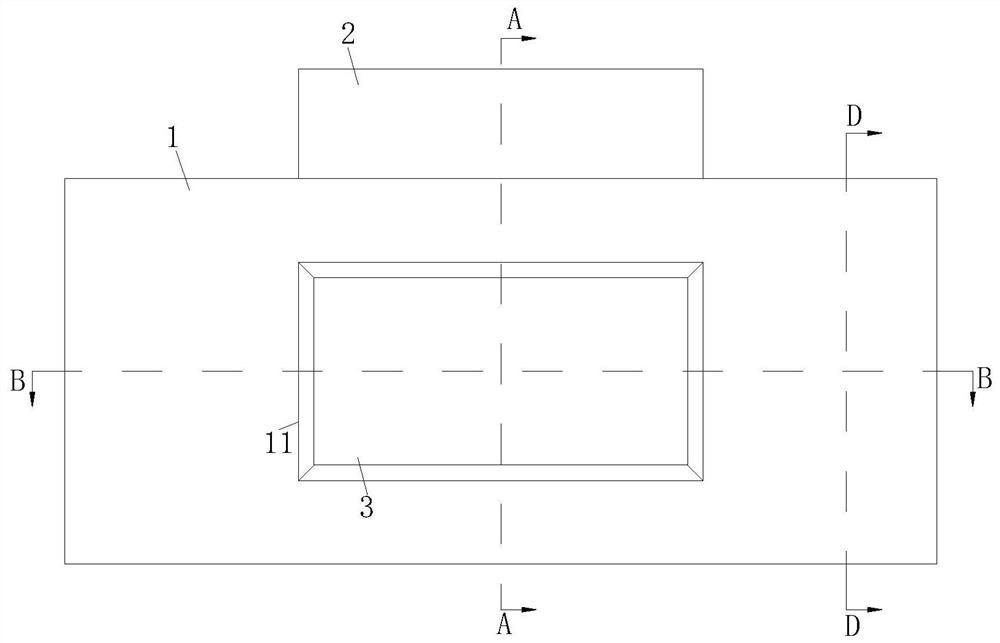

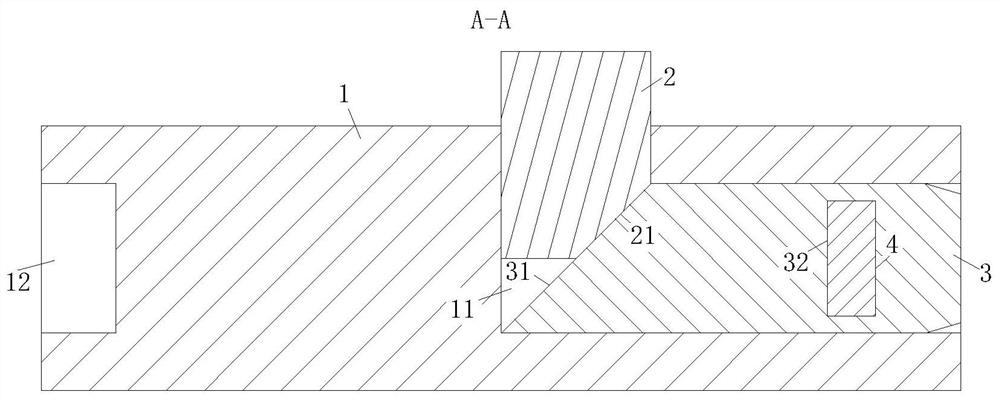

[0035] As an embodiment of the present invention, the outer wall of the brick body 1 is provided with a through groove 13; the outer wall of the brick body 1 provided with the through groove 13 is adjacent to the outer wall near the other end of the L-shaped groove 11 Setting; the cross-sectional shape of the through groove 13 is a rectangle, the through groove 13 is connected to the inside of the L-shaped groove 11, and the through groove 13 is slidably connected to the second block 4; the cross-sectional shape of the second block 4 is a right-angled trapezoid The outer wall of the No. 2 block 4 near the No. 1 block 3 is a No. 3 inclined plane 41; the outer wall of the No. 1 block 3 near the No. 2 block 4 is provided with a groove 32; the groove 32 The cross-sectional shape is a right triangle; one end of the second block 4 is stuck in the groove 32; the first block 3 can squeeze the second block 4 to slide along the groove wall of the through groove 13; the brick The outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com