Floor slab through type steel-concrete combined flat beam floor system structure and building thereof

A concrete and floor technology, applied to floors, buildings, building components, etc., can solve problems such as difficulty in implementation, poor anti-corrosion and fire protection performance, and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

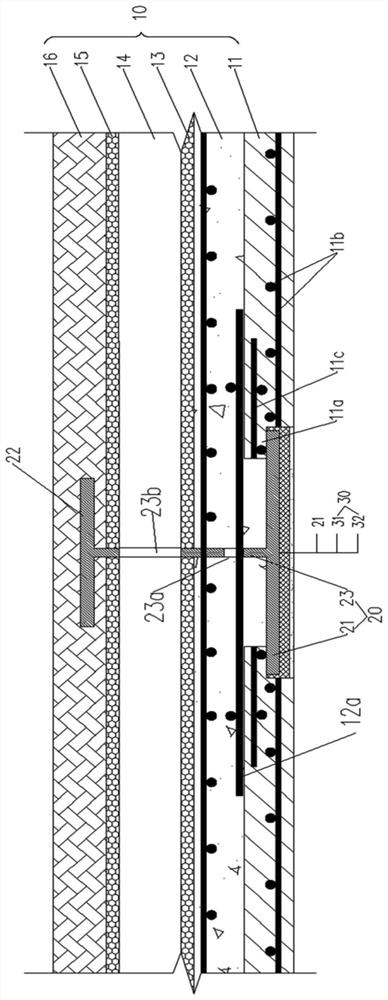

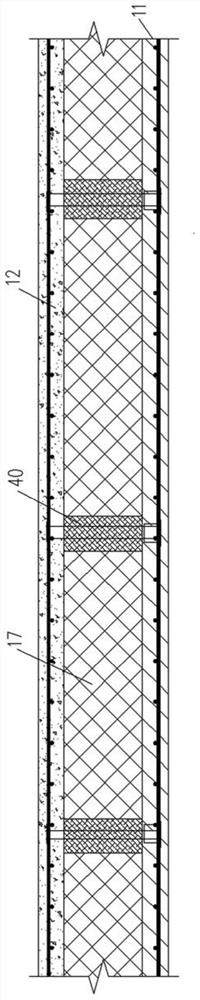

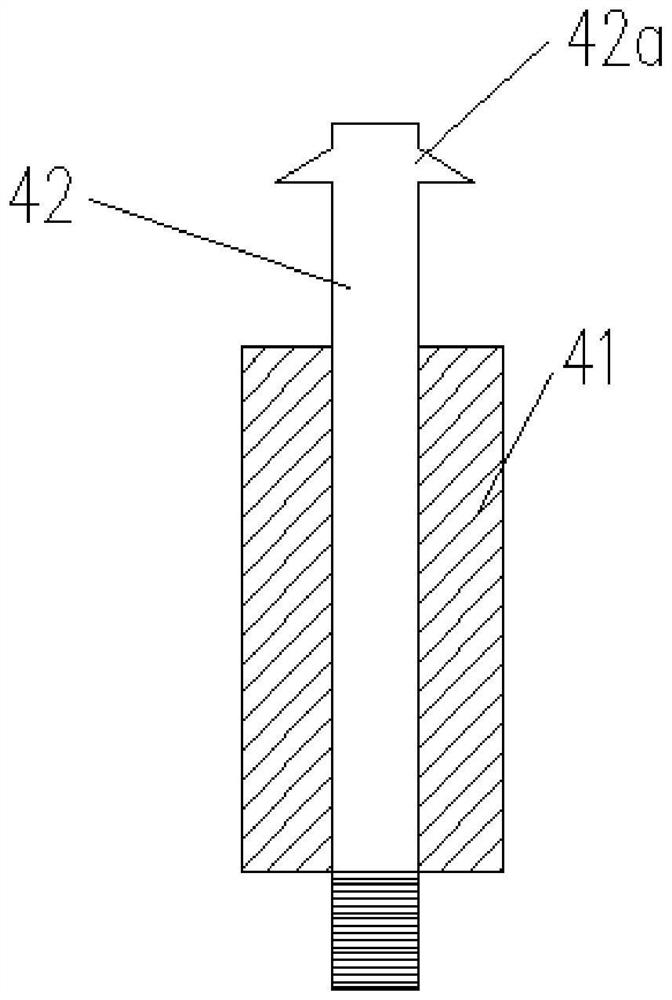

[0058] like figure 1 As shown, the under-floor steel-concrete composite flat beam floor structure provided in this embodiment includes: a floor 10 and a steel beam 20; the steel beam 20 is hidden within the height range of the floor 10 .

[0059] The floor 10 includes a concrete precast slab 11 and an existing structural layer; the steel beam 20 includes an upper flange 22, a lower flange 21 and a web 23; the end of the concrete precast slab 11 includes an overlapping portion 11a , the overlapping portion 11a is overlapped on the lower flange 21; the existing structural layer is laid above the concrete prefabricated slab 11, and the upper flange 22 is embedded in the existing structural layer . The web 23 is provided with a reinforcement hole 23a and a pipeline hole 23b at intervals, which are respectively used for piercing the perforated steel bar and the pipeline of the ground heating layer 14, and allows the concrete on both sides of the web 23 to pass through to improve ...

Embodiment 2

[0087]The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0088] like Figure 7 As shown, the steel beam 20 is an equal-flange steel beam 20, and one or several gaps 22b are opened on the upper flange 22, and the overlapping portion 11a of the prefabricated concrete slab 11 is inserted into the upper flange 22 from the outside through the gap. and the lower flange 21 , the rear translations are arranged side by side in sequence, and finally lapped on the lower flange 21 .

[0089] like Figure 8 As shown, it also includes a rib plate 60 for covering the gap and reinforcing the gap; after the prefabricated concrete panel 11 is installed, the rib plate covers the gap, and the two ends of the rib plate pass through The bolts are fixedly connected to the edges on both sides of the gap in the upper flange 22 .

[0090] The upper flange 22 and the lower flange 21 of the equal-flange steel beam 20 clamp the overlapping portion ...

Embodiment 3

[0092] This embodiment discloses a building adopting the above-mentioned under-floor steel-concrete composite flat beam floor structure, which also includes a composite column for supporting the steel beam.

[0093] like Figure 15 As shown, the two ends of the steel beam 20 are connected to the steel pipe 110 in the laminated column 100 through the extended corbel 160 , and the steel beam 20 is hidden within the height range of the floor 10 .

[0094] like Figure 9 As shown, the composite column 100 includes a steel pipe 110, a concrete column 120 filled in the tube, a concrete layer 130 outside the tube, and a steel skeleton; the steel tube 110 is provided with a concrete column 120 filled in the tube formed by filling and pouring during prefabrication; the concrete layer 130 outside the tube is wrapped in The outer side of the steel pipe 110; the steel skeleton is buried in the concrete layer 130 outside the pipe; the two ends of the steel pipe 110 are respectively provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com