Efficient coal injection machine

A coal injection machine, high-efficiency technology, applied in the direction of combustion method, block/powder supply/distribution, supply configuration, etc., can solve the problems of inability to raise the temperature of the smelting furnace and reduce the smelting efficiency, so as to reduce the grinding process and shorten the smelting Time, the effect of improving smelting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

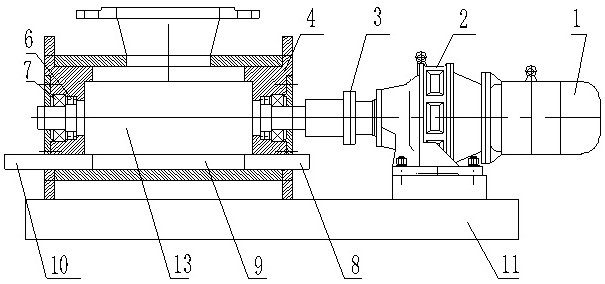

[0021] Embodiment 1: The coal injection machine includes: a motor 1, a reducer 2, a coupling 3, a base 11 and a coal mixer; the coal mixer is installed on the base 11, and there is a feed port at the upper end of the coal mixer; There is a reducer 2 at one end of the coal mixer, the input shaft of the reducer 2 is connected with the output shaft of the motor 1, and the output shaft of the reducer 2 is connected with the rotor shaft 12 of the coal mixer through a coupling 3.

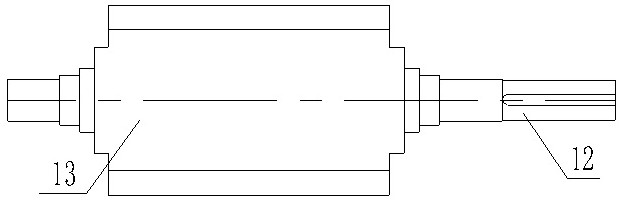

[0022] The coal mixer includes: body 4, sealing ring 6, bearing 7, air inlet 8, coal injection outlet 10, rotor shaft 12, rotor 13 and fins 14; both ends of rotor 13 are connected to the body through bearing 7 At both ends of 4, a seal ring 6 is connected to the rotor shaft inside the bearing 7; in the middle of the body 4 there is a rotor cavity matched with the rotor 13, and the rotor is located in the rotor cavity; on the side wall of the body 4 there is The coal inlet corresponding to the feed port, t...

Embodiment 2

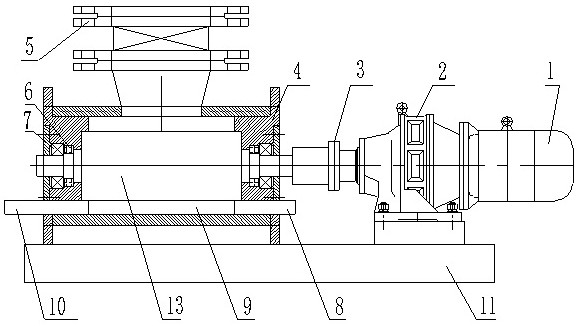

[0028] Example 2: figure 2 Among them, the coal injection machine also includes: a coal inlet valve 5; a coal inlet valve 5 is installed on the feed port at the upper end of the coal mixer. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com