A self-pulsation and continuous output silicon-based integrated semiconductor laser based on fano resonance and its preparation method

A laser and self-pulsation technology, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of low coupling efficiency and large transmission loss, and achieve high injection efficiency, large process tolerance, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

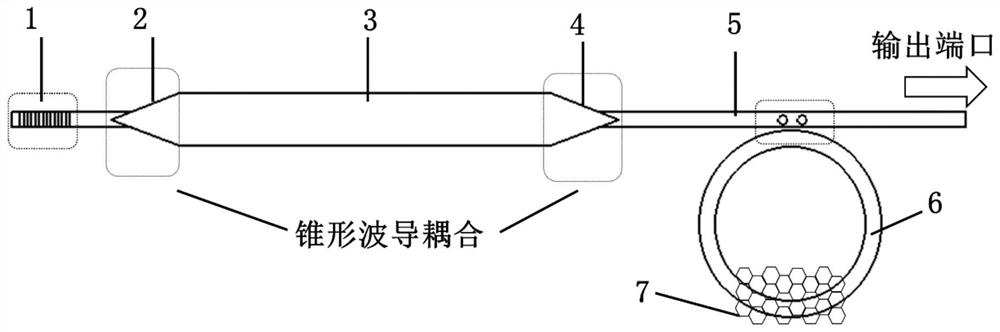

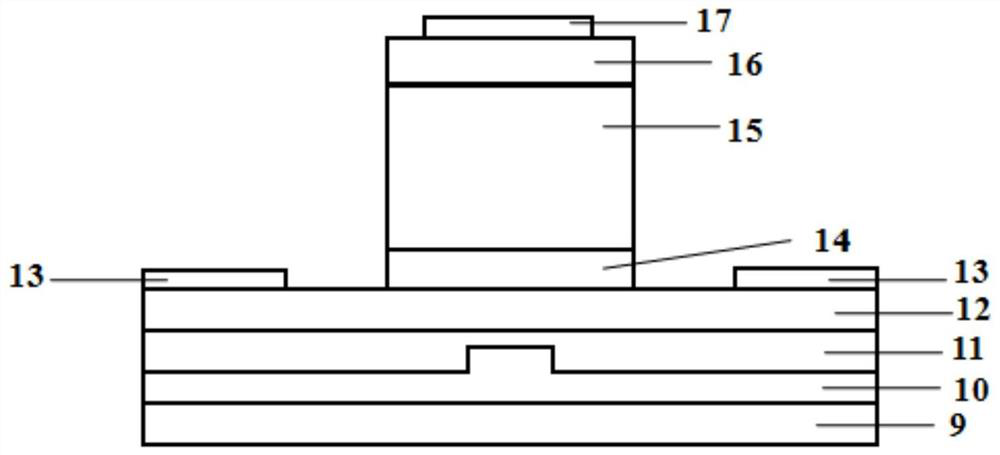

[0078] A silicon-based integrated laser with self-pulsing and continuous output, such as figure 1 As shown, the laser includes a substrate and a Bragg mirror 1, a first tapered waveguide 2, a III-V multi-quantum well active region 3, and a second tapered waveguide 4 arranged on the substrate from left to right And Fano reflector, substrate adopts SOI substrate in the present embodiment, and SOI substrate comprises SiO 2 Substrate 9 and silicon waveguide layer 10.

[0079] The Bragg reflector 1 is connected with the narrow end of the first tapered waveguide 2, and the wide end of the first tapered waveguide 2 is connected with one end of the III-V family multi-quantum well active region 3, and the III-V group multi-quantum well The other end of the active region 3 is connected to the wide end of the second tapered waveguide 4, and the narrow end of the second tapered waveguide 4 is connected to the Fano mirror;

[0080] The Fano reflector comprises a straight waveguide 5 and ...

Embodiment 2

[0088] According to the silicon-based integrated laser with self-pulse and continuous output provided in Embodiment 1, the difference lies in:

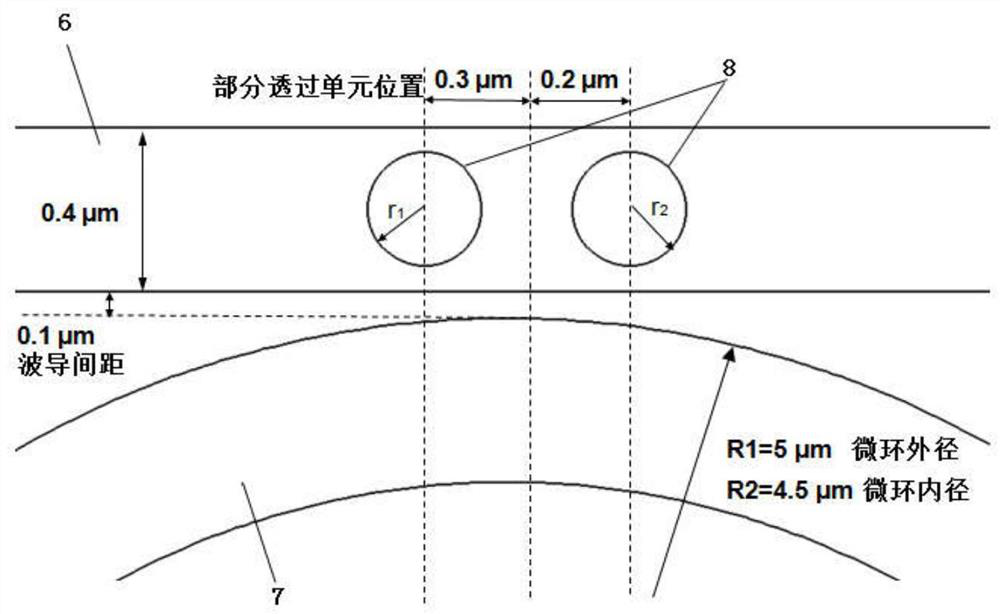

[0089] Such as Figure 1a As shown, the distance between the straight waveguide 5 and the microring is 0.1 μm; the width of the straight waveguide 5 is 0.4 μm; the outer diameter of the microring is 5 μm, and the inner diameter of the microring is 4.5 μm.

[0090] The partially permeable unit 8 includes two air holes, and the two air holes are arranged on both sides of the vertical line from the center of the microring waveguide 6 to the straight waveguide 5; and the distances from the two air holes to the vertical line are different.

[0091] This design is mainly to obtain the optimal Fano reflection spectrum, which maximizes the additional phase shift Δφ, thereby maximizing the symmetry and reflection intensity of the reflection spectrum.

[0092] Introduce a radius r into the straight waveguide 5 1 and r 2 After two air holes, ...

Embodiment 3

[0121] A silicon-based integrated laser with self-pulse and continuous output provided according to Embodiment 2, the difference is that:

[0122] The shape of the air hole is ellipse, the side length of the long axis of the ellipse is 0.22-0.3 μm, and the side length of the short axis is 0.16-0.28 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com